Bleaching and dyeing wastewater treatment method with combination of advanced oxidation and ultrafiltration

An advanced oxidation and wastewater treatment technology, applied in the field of water treatment, can solve the problems of lack of water treatment technicians in bleaching and dyeing factories, the inability to meet the outlet of bleaching and dyeing wastewater, and the difficulty of long-term stable operation of biological methods, so as to achieve excellent effluent quality and eliminate concentration extremes The effect of modernization and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

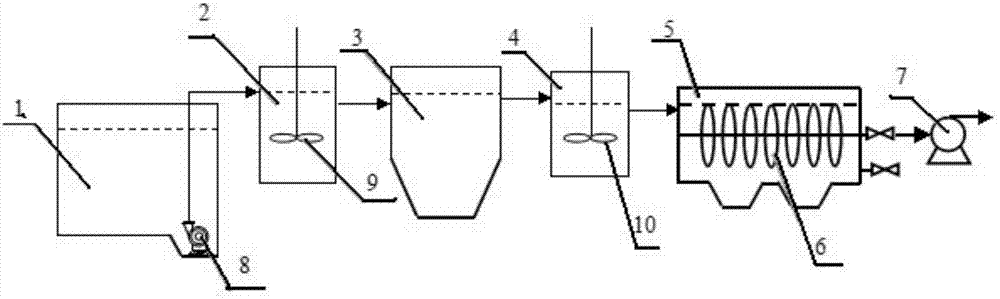

[0029] This embodiment discloses a bleaching and dyeing wastewater treatment method combining advanced oxidation and ultrafiltration membrane separation, including the following steps:

[0030] The first step, pretreatment in the adjustment tank: put several kinds of bleaching and dyeing wastewater in the adjustment tank, adjust the water volume and pH of the bleaching and dyeing wastewater, and adjust the pH value of the bleaching and dyeing wastewater to 3.0-4.0.

[0031] The second step, first-level advanced oxidation treatment: transport the bleaching and dyeing wastewater in the adjustment tank to the first-level advanced oxidation tank, add ferrous ions and hydrogen peroxide, and oxidize and decompose the dyes and part of COD in the bleaching and dyeing wastewater. The wastewater treated by advanced oxidation enters the sedimentation tank. The amount of ferrous ions and hydrogen peroxide added is: 0.2-0.4mg / L ferrous ions, 0.6-1.2ml / L hydrogen peroxide, after adding the ...

Embodiment 2

[0042] In Example 2, the bleaching and dyeing wastewater treatment was carried out with the combination of secondary advanced oxidation and ultrafiltration membrane separation technology disclosed in Example 1: the original wastewater COD was about 760mg / L, and the chromaticity was 824 times. After the combined system in Example 1: After the secondary advanced oxidation and ultrafiltration membrane separation process, the effluent COD<200mg / L, chroma<10, characteristic pollutant indicators and conventional water quality indicators meet the "Water Pollutant Discharge Standard for Textile Dyeing and Finishing Industry" (GB4287-2012).

[0043] It can be seen from this that the bleaching and dyeing wastewater treatment method of the present invention aims at the problem that the bleaching and dyeing wastewater is difficult to degrade, by setting up a secondary advanced oxidation tank, under the action of an advanced oxidant, the macromolecular refractory organic matter in the bleach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com