Resource reutilization method by utilization of copper-clad plate residue

A copper-clad laminate and recycling technology, which is applied in the field of resource recycling of copper-clad laminate residues, can solve problems such as waste copper-clad laminate pollution, and achieve the effects of environmental protection, good dispersion, and environmentally friendly preparation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

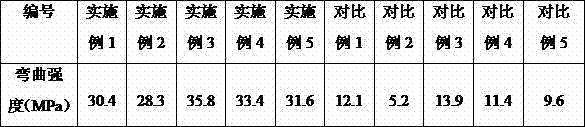

Examples

Embodiment 1

[0028] Based on the weight of the copper clad laminate residue, put the residue of the waste copper clad laminate after the copper extraction treatment (by mass percentage, the main components are 30% cured resin, 68% glass fiber, and 2.0% copper;) into 0.1% mass concentration sulfuric acid Soak in the solution for 5 hours, then add 0.5% methyl tri-tert-butyl peroxysilane coupling agent and 1.5% KH570 coupling agent, soak for another 2 hours, pick up the copper clad laminate residue and dry it at 120°C for 1 hour hour, obtain the copper clad laminate residue after pretreatment;

[0029] In terms of weight percentage, 60% of the pretreated copper-clad laminate residue, 20% of calcium carbonate powder, and 20% of m-phenylene neopentyl glycol type unsaturated polyester are weighed, stirred and mixed evenly, and molded into The uniformly mixed mixture is poured into a steel mold to make a square billet, and then cured at a constant temperature of 100°C, cut into a plate-shaped mat...

Embodiment 2

[0031] Based on the weight of the copper clad laminate residue, put the residue of the waste copper clad laminate after the copper extraction treatment (by mass percentage, the main components are 30% cured resin, 69.9% glass fiber, and 0.1% copper) into a 1.0% mass concentration sulfuric acid solution Soak for 2 hours, then add 1.5% ethylene tri-tert-butylperoxysilane coupling agent and 0.5% KH570 coupling agent, soak for another 0.5 hour, pick up the copper clad laminate residue and dry it at 100°C for 2 hours. Obtain the pretreated copper clad laminate residue;

[0032]In terms of weight percentage, 70% of the pretreated copper-clad laminate residue, 20% of calcium carbonate powder, and 10% of epoxy resin are weighed, stirred and mixed evenly, and molded by pouring to form a uniformly mixed mixture. In the steel mold, a square blank is made, and after being cured at a constant temperature of 120°C, it is cut into a plate-shaped material of 1000mm×1000mm×15mm, and the surfac...

Embodiment 3

[0034] Based on the weight of the copper clad laminate residue, put the residue of the waste copper clad laminate after the copper extraction treatment (by mass percentage, the main components are 50% cured resin, 49% glass fiber, and 1.0% copper) into 0.6% mass concentration sulfuric acid solution soak for 2.5 hours, then add 1.0% allyl tri-tert-butylperoxysilane coupling agent and 1.0% KH570 coupling agent, soak for another 1.5 hours, pick up the copper clad laminate residue and dry it at 120°C for 1 hour , to obtain the pretreated copper clad laminate residue;

[0035] In terms of weight percentage, 40% of the pretreated copper-clad laminate residue, 20% of calcium carbonate powder, and 40% of phenolic resin are weighed, stirred and mixed evenly, and molded by casting. In the mold, a square blank is made, and after being cured at a constant temperature of 100°C, it is cut into a plate-shaped material of 800mm×800mm×15mm, and the surface is polished to a mirror image glossin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com