Method for controlling amount of hydrated silicatein crystal water in high-silicon-copper-matte oxygen-pressure acid leaching

A sulfonium oxybaric acid and silicoprotein technology, which is applied in the direction of improving the process efficiency, can solve the problems of not mentioning the form of silica, not involving the sedimentation performance of the leaching pulp, the volume content of the filter cake and the water content, etc. Conducive to the process volume balance, reducing the amount of washing water and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

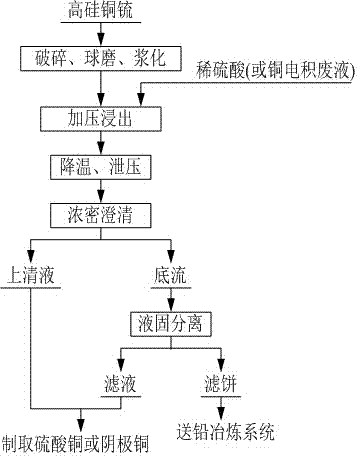

Image

Examples

Embodiment 1

[0019] The method for controlling the crystallization water amount of hydrated silicon protein in the described high-silicon copper sulfonium oxygen pressure acid leaching adopts the following steps to realize:

[0020] (1) After the high-silicon copper matte is crushed and ball-milled, it is slurried with clear water, and the concentration of the slurry is controlled to 0.8g / mL according to the silica content of the raw material;

[0021] (2) Separately and continuously pump the ore pulp and copper electrowinning waste liquid into the autoclave, and control the liquid-solid ratio of the raw material into the autoclave to 5:1 according to the silica content of the raw material;

[0022] (3) Oxygen is continuously introduced into the autoclave;

[0023] (4) According to the silicon dioxide content of the raw material, the temperature in the autoclave is controlled to 130°C, the total pressure is 0.6Mpa, and the reaction time is 2.0h. The silicon dioxide in the copper matte is ...

Embodiment 2

[0030] The method for controlling the crystallization water amount of hydrated silicon protein adopts the following steps to realize during the described high-silicon copper sulfonium oxygen pressure acid leaching:

[0031] (1) After the high-silicon copper matte is crushed and ball-milled, it is slurried with clean water, and the concentration of the slurry is controlled to 1.1 g / mL according to the silica content of the raw material.

[0032] (2) Separately and continuously pump the ore pulp and copper electrowinning waste liquid into the autoclave, and control the liquid-solid ratio of the raw material into the autoclave to be 4:1 according to the silica content of the raw material.

[0033] (3) Oxygen is continuously introduced into the autoclave.

[0034] (4) According to the silicon dioxide content of the raw material, the temperature in the autoclave is controlled to 140°C, the total pressure is 0.7Mpa, and the reaction time is 2.5h. The silicon dioxide in the copper m...

Embodiment 3

[0041] The method for controlling the crystallization water amount of hydrated silicon protein adopts the following steps to realize during the described high-silicon copper sulfonium oxygen pressure acid leaching:

[0042] (1) After the high-silicon copper matte is crushed and ball-milled, it is slurried with clean water, and the concentration of the slurry is controlled to 1.4 g / mL according to the silica content of the raw material.

[0043] (2) Separately and continuously pump the ore pulp and copper electrowinning waste liquid into the autoclave, and control the liquid-solid ratio of the raw material into the autoclave to be 3:1 according to the silica content of the raw material.

[0044] (3) Oxygen is continuously introduced into the autoclave.

[0045] (4) According to the silicon dioxide content of the raw material, the temperature in the autoclave is controlled to 150°C, the total pressure is 0.8Mpa, and the reaction time is 3.0h. The silicon dioxide in the copper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com