Super capacitor battery

A super capacitor and battery technology, applied in lead-acid batteries, lead-acid battery electrodes, hybrid capacitor electrodes, etc., can solve problems such as high energy density and power density, poor utilization of active materials and electron transfer capacity, and plate thickness. , to achieve the effect of strong electrical conductivity, increased effective contact area, and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: The supercapacitor storage battery provided in this embodiment is mainly used for the No. 1 rechargeable battery.

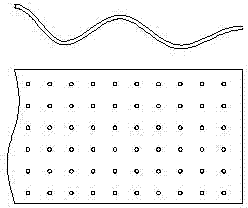

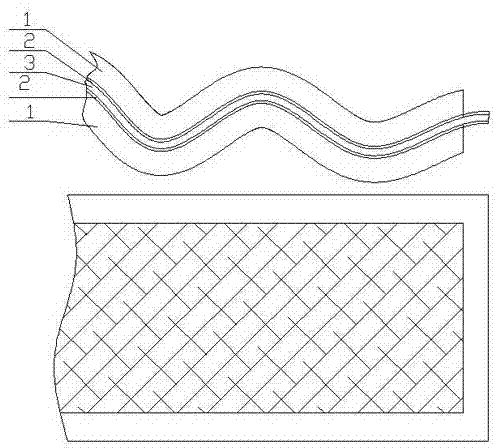

[0024] Choose a lead foil with a thickness of 0.05mm, spray a mixture of PTFE, graphene, and activated carbon with a thickness of 0.01mm, and the ratio of PTFE, graphene, and activated carbon is 1:1:8, and then treat it according to the conventional formula. After coating the lead foil, the total thickness of the plate after coating the lead paste is 0.2mm, and then select a separator with a thickness of 0.2mm, and wrap the sheet according to the method of separator-negative plate-separator-positive plate. A super capacitor is wound into a battery, and the dimensions of the battery are as follows: hollow 5mm, diameter 30mm, height 50mm. Its capacity can reach 4Ah. Performance and cost performance are higher than AA rechargeable Ni-MH batteries of the same size.

Embodiment 2

[0025] Embodiment 2: The supercapacitor battery provided in this embodiment is mainly used for electric bicycle batteries.

[0026] Choose a lead foil with a thickness of 0.1mm, spray a mixture of PTFE, graphene, and activated carbon with a thickness of 0.02mm, and the ratio of PTFE, graphene, and activated carbon is 1:2:7, and then treat it according to the conventional formula The final lead foil is coated, and the total thickness of the plate is 0.3mm after the lead paste is coated, and then a separator with a thickness of 0.3mm is selected, and the plate is actually wrapped according to the method of separator-negative plate-separator-positive plate, and the production A supercapacitor is wound into a battery, and then a battery pack is made by connecting in series and parallel. The dimensions of the wound battery are as follows: hollow 8mm, diameter 85mm, and height 170mm. Its capacity can reach 30Ah. The charging acceptance capacity and high current discharge capacity a...

preparation example 1

[0029] Take 1Kg of water, add 20g of PTFE under the condition of constant stirring, after the PTFE is completely dissolved, continue to stir, add 20g of graphene, after the graphene is added, disperse the mixed solution with a high-speed disperser, and finally process it The active material composite layer material was loaded into the spray gun, and a uniform layer of active material composite layer material with a thickness of 5 μm was sprayed on both sides of the 0.05 mm thick lead foil. Compared with the wound lead-acid battery that has not been treated with the lead foil, the wound lead-acid battery prepared with the lead foil treated with the active material composite layer material has a very large advantage in life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com