Preparation method of alumina coated lithium titanate

A technology of lithium titanate and alumina, which is applied in the direction of electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of lithium titanate flatulence and other problems, achieve the effects of reducing water absorption, improving flatulence problems, and reducing decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

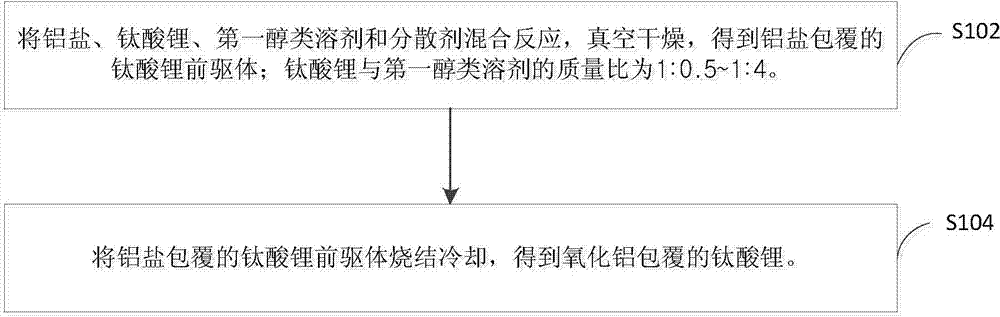

[0037] refer to figure 1 , a preferred embodiment of the present invention provides a method for preparing alumina-coated lithium titanate, comprising the following steps:

[0038] S102: Mix and react the aluminum salt, lithium titanate, the first alcoholic solvent and the dispersant, and dry in vacuum to obtain a lithium titanate precursor coated with the aluminum salt; the mass ratio of lithium titanate to the first alcoholic solvent is 1 :0.5~1:4.

[0039] S104: Sintering and cooling the aluminum salt-coated lithium titanate precursor to obtain aluminum oxide-coated lithium titanate.

[0040] During the mixing process, the first alcohol solvent is used as a dispersion medium, which can promote the dispersion of the aluminum salt and lithium titanate, avoid agglomeration, and make the aluminum salt and lithium titanate fully contact, so as to accelerate the reaction speed. Due to the low boiling point of the alcohol solvent, it volatilizes quickly during the vacuum drying ...

Embodiment 1

[0056] Add 100g of aluminum sulfide to 400g of ethanol solution, and grind in a sand mill until the D50 (median particle size) is 0.5um to obtain a suspension of aluminum sulfide in ethanol solution.

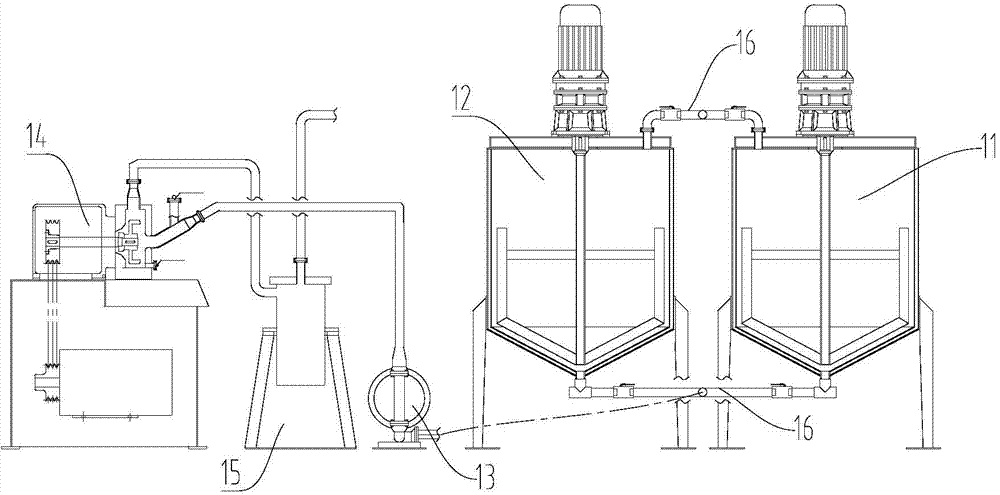

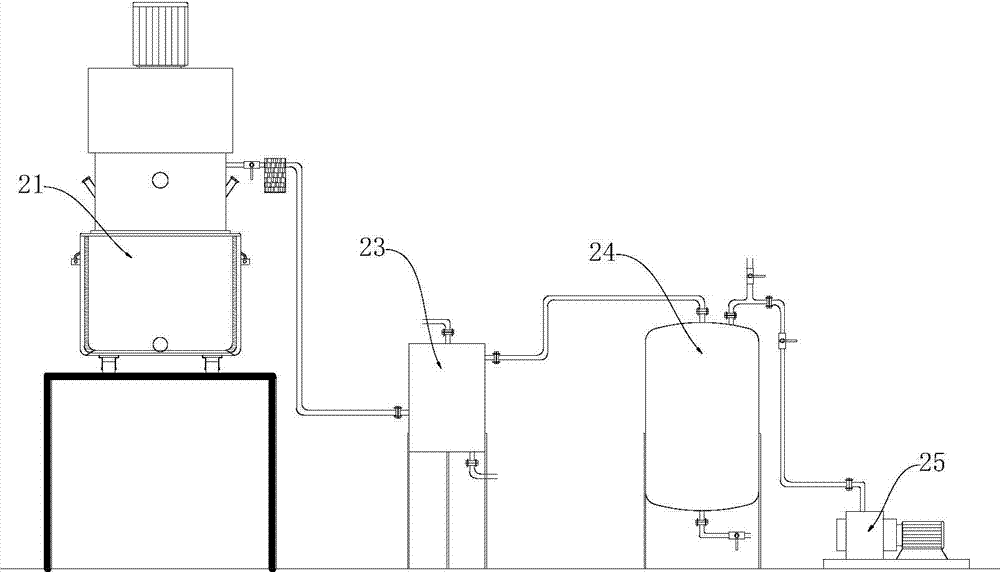

[0057] Add 1000g of lithium titanate with a particle size of 6 microns, 500g of ethanol solution and 2g of polyammonium methacrylate into the dispersion mixing tank of the multifunctional coating mixer, stir to form a lithium titanate suspension, and then add the ethanol solution of aluminum sulfide Suspension. After stirring and reacting for 30 minutes, vacuum drying was carried out at 0.4 MPa and 50° C. to obtain an aluminum salt-coated lithium titanate precursor. Condensed ethanol is recovered at the receiving tank.

[0058] The aluminum salt-coated lithium titanate precursor was sintered at 300° C. for 10 h, and then aluminum oxide-coated lithium titanate was obtained after cooling.

Embodiment 2

[0060] Add 100g of aluminum isopropoxide into 1000g of ethanol solution, and grind in a sand mill until the D50 is 0.5um to obtain a suspension of aluminum isopropoxide in ethanol solution.

[0061] Add 3000g of lithium titanate with a particle size of 30 microns, 6000g of isopropanol solution and 15g of polyammonium methacrylate into the dispersion mixing tank of the multifunctional coating mixer, stir to form a lithium titanate suspension, and then add isopropanol Aluminum suspension in ethanol. After stirring and reacting for 40 minutes, it was vacuum-dried at 0.6 MPa and 60° C. to obtain a lithium titanate precursor coated with aluminum salt. Condensed ethanol is recovered at the receiving tank.

[0062] The aluminum salt-coated lithium titanate precursor was sintered at 400° C. for 15 hours, cooled and sieved to remove iron to obtain aluminum oxide-coated lithium titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com