Nanometer porous gold composite electrode material modified by nanometer metal oxide and preparation method thereof

A nanoporous gold and nanometal technology, applied in nanotechnology, battery electrodes, nanotechnology, etc. for material and surface science, can solve the problems of loss of catalytic activity, high cost, poisoning, etc., and achieve improved anti-poisoning performance, The effect of low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

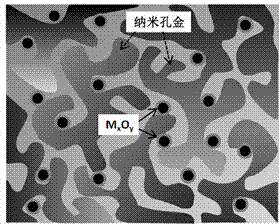

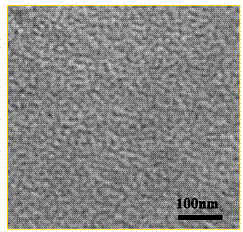

[0034] A nanoporous gold composite electrode material modified by nanometer metal oxides, that is, nanoscale metal oxides are filled in the pores of the nanoporous gold film, and the pore size of the nanoporous gold film needs to be the size of the metal oxide particle 2-4 times, the schematic diagram of its structure is as follows figure 1 as shown, figure 1 Among them, MxOy represents nanoscale metal oxides, and nanoporous gold represents nanoporous gold films;

[0035] Its pore size of described nanoporous gold film is 8nm, and porosity is 65%;

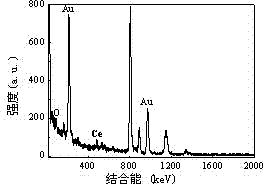

[0036] The metal oxide is Ce 2 o 3 .

[0037] A nanoporous gold composite electrode material modified by a nanometer metal oxide, which is prepared by a method comprising the following steps:

[0038] (1) Preparation of metal oxide sol:

[0039] The metal nitrate is Ce (NO 3 ) 3 Dissolve in pure water to obtain a metal salt solution with a concentration of metal Ce ions of 0.1 mM, then adjust the pH to 5 with ammonia water,...

Embodiment 2

[0046] A nanoporous gold composite electrode material modified by nanometer metal oxides, that is, nanoscale metal oxides are filled in the pores of the nanoporous gold film, and the pore size of the nanoporous gold film needs to be the size of the metal oxide particle 2-14 times;

[0047] The nanoporous gold film has a size of 40nm and a porosity of 50%;

[0048] The metal oxide is TiO 2 .

[0049] A nanoporous gold composite electrode material modified by a nanometer metal oxide, which is prepared by a method comprising the following steps:

[0050] (1) Preparation of metal oxide sol:

[0051] Dissolve the metal organic acid salt, namely ethyl titanate, in ethanol to obtain a metal salt solution with a concentration of metal Ti ions of 0.1M, then adjust the pH to 9 with ammonia water, and then add the surfactant polyvinyl alcohol-400 to make the surface After the concentration of the active agent polyvinyl alcohol-400 is 0.2M, emulsify at room temperature for 10 minutes ...

Embodiment 3

[0061] A nanoporous gold composite electrode material modified by nanometer metal oxides, that is, nanoscale metal oxides are filled in the pores of the nanoporous gold film, and the pore size of the nanoporous gold film needs to be the size of the metal oxide particle 13-60 times;

[0062] The nanoporous gold film has a pore size of 120nm and a porosity of 30%;

[0063] The metal oxide is Eu 2 o 3 .

[0064] A nanoporous gold composite electrode material modified by a nanometer metal oxide, which is prepared by a method comprising the following steps:

[0065] (1) Preparation of metal oxide sol:

[0066] Metal nitrate Eu (NO 3 ) 3 Dissolve in pure water to obtain a metal salt solution with a concentration of metal Eu ions of 0.5 mM, then adjust the pH to 6 with ammonia water, and then add the surfactant trimethyl phosphate to make the concentration of the surfactant trimethyl phosphate 0.4 After mM, emulsify at room temperature for 30 minutes to obtain a metal oxide wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com