Preparation method of hybrid adsorbent for removing heavy metal nickel ions in water

A technology for removing water and adsorbents, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. Short life and other problems, to achieve the effect of improving removal effect, simple preparation method and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

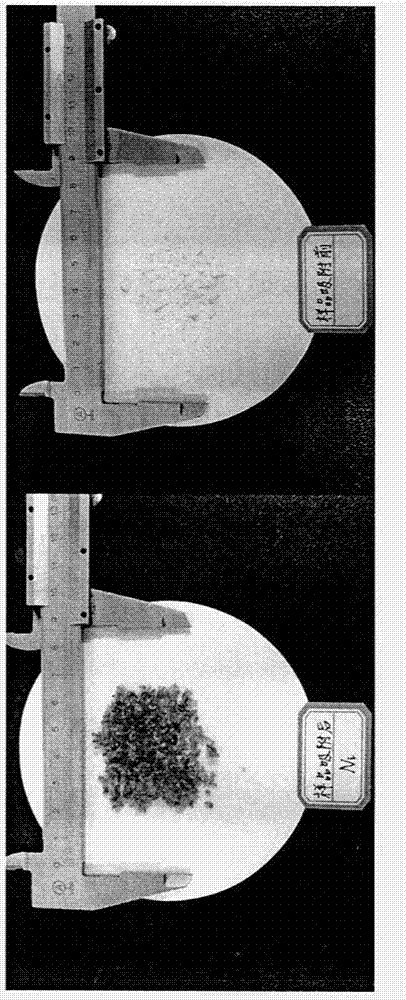

Image

Examples

Embodiment 1

[0031] Embodiment 1. prepares the hybrid adsorbent for removing heavy metal nickel ions in water with the reactant volume ratio silane coupling agent: epichlorohydrin=4:1

[0032] First put a clean beaker on a magnetic stirrer, in an air or nitrogen atmosphere, at a temperature of 25°C (usually the reaction temperature is 0-100°C, and in this embodiment, it is selected at a room temperature of 25°C) , add 4mL of silane coupling agent N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (abbreviated as A-1120) into the beaker, then add 1mL of epichlorohydrin solution dropwise, continuously Stir to make them carry out sol-gel reaction at 25°C for 4h, continue to stir for 20h to obtain the sol-gel reaction product (usually the sol-gel reaction time is 1-48h, in order to make the reaction more complete, the present embodiment The sol-gel reaction has been carried out for 24h); the sol-gel reaction product was cooled and defoamed for 24h, and then it was placed in a drying oven, and the ...

Embodiment 2

[0037] Embodiment 2. prepare the hybrid adsorbent for removing heavy metal nickel ions in water with reactant volume ratio silane coupling agent: epichlorohydrin=4:1

[0038] Using the same experimental device, operating steps and the same ingredient ratio as in Example 1, the sol-gel reaction product prepared above was directly and slowly poured onto a clean, dry polytetrafluoroethylene plate to scrape the film, and at room temperature Place it for 24 hours, then put it in a constant temperature drying oven, convectively dry it at 90°C for 24 hours, and remove the membrane from the PTFE plate after cooling in the air to obtain a membrane-shaped membrane without a support. A hybrid adsorbent for the removal of heavy metal nickel ions in water.

[0039] The results of adsorption experiments show that: at 25°C and pH=4, its 2+ The adsorption capacity is 51.09 mg / g, which shows that the hybrid adsorbent can adsorb heavy metal nickel ions in water.

[0040] To sum up: this examp...

Embodiment 3

[0041] Embodiment 3. prepare the hybrid adsorbent for removing heavy metal nickel ions in water with reactant volume ratio silane coupling agent: epichlorohydrin=4:1

[0042] Using the same experimental device, operating steps and the same proportioning ratio as in Example 1, first dissolve the silane coupling agent with 20mL of N,N-dimethylformamide, and then slowly add 1mL of epichlorohydrin solution dropwise , keep stirring to make them carry out sol-gel reaction at 25°C for 6 hours, and continue to stir for 18 hours to obtain a sol-gel reaction product. The obtained sol-gel reaction product is left standing for defoaming, and then the standing The defoamed substance was dried for 48 hours at 200°C and 90% relative humidity in nitrogen to obtain a rod-shaped hybrid adsorbent that can be used to remove heavy metal nickel ions in water.

[0043] The results of the adsorption experiment show that at 25°C and pH=5, its 2+ The adsorption capacity is 49.67 mg / g, which shows that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com