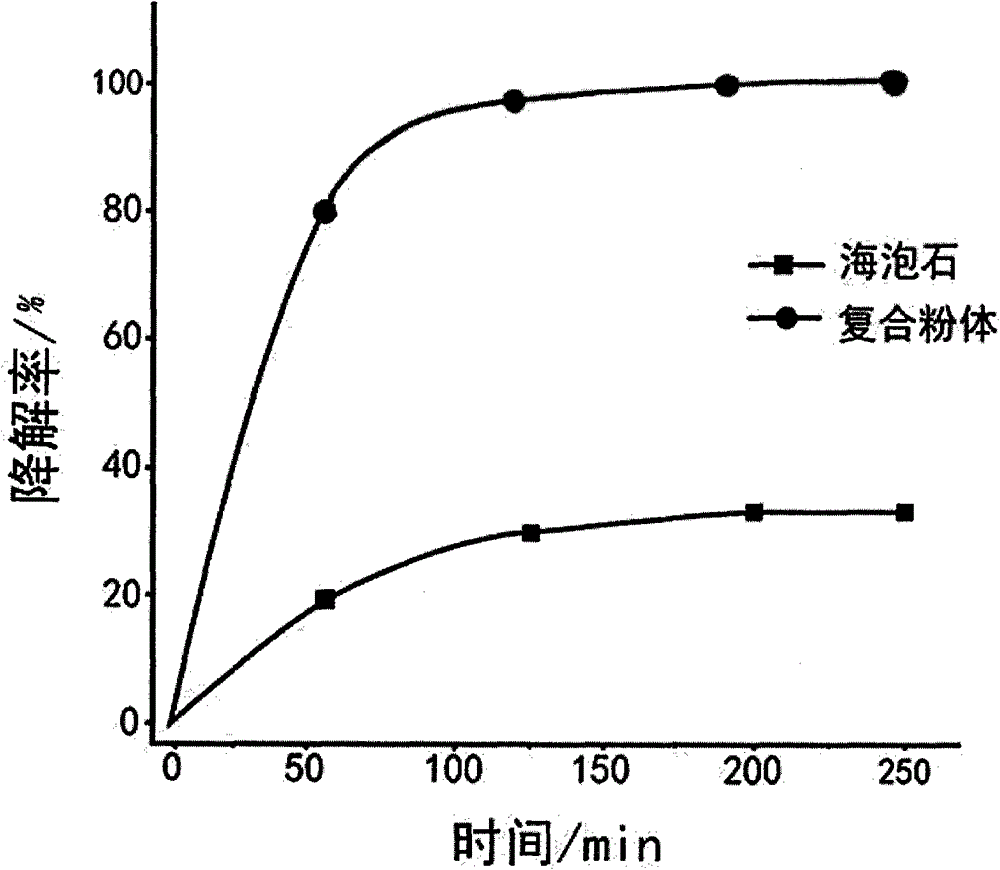

Preparation method and use of nano TiO2/sepiolite composite material

A composite material and sepiolite technology, which is applied in the field of preparation of nano-TiO2/sepiolite composite materials, can solve the problems of harsh conditions, complex process, difficult operation, etc., and achieves low production cost, simple process steps, and control of formaldehyde. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: this embodiment provides a kind of nano-TiO 2 / The preparation method of sepiolite composite material, it comprises the following steps:

[0036] (1) Stir and mix sepiolite and water with a solid-to-liquid ratio of 0.5 to 1.5: 9 to 11 to obtain the first mixed solution; the solid-to-liquid ratio of sepiolite and water is preferably 1: 10; and the stirring and mixing time is 25 ~35 min, preferably 30 min.

[0037] (2) Select the intermediate suspension suspended in the middle of the first mixed solution; specifically, it includes the following steps: (2.1) after the first mixed solution is left to stand for 25 to 35 minutes, preferably after 30 minutes, remove the supernatant and For the sediment at the bottom, take the intermediate suspension; (2.2) stir and disperse the intermediate suspension for 25 to 35 minutes, preferably after 30 minutes, then let it stand for 25 to 35 minutes, preferably 30 minutes; (2.3) remove the static mixture in step (2.2). The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com