Method for preparing sandwich structure diamond-Al composite material

A composite material and diamond technology, applied in the field of preparation of sandwich structure diamond-Al composite materials, can solve problems such as difficulty in controlling the thickness of the copper layer, and achieve the effects of machinability, low thermal resistance, and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

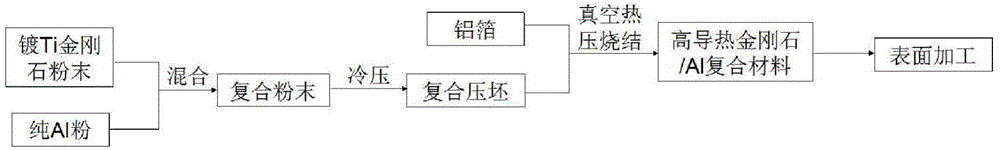

Method used

Image

Examples

Embodiment 1

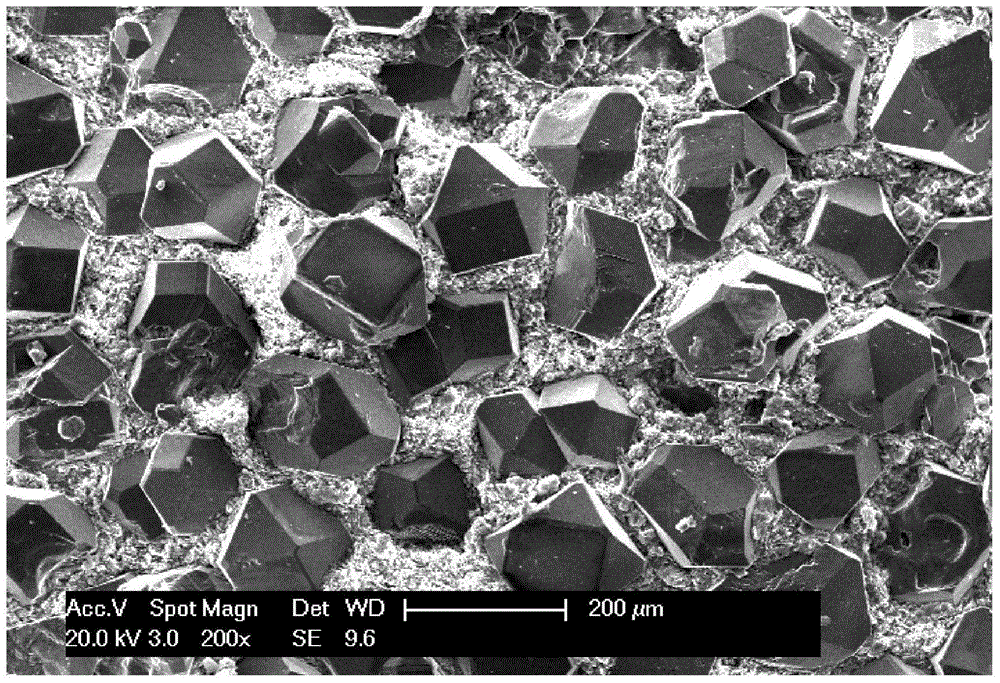

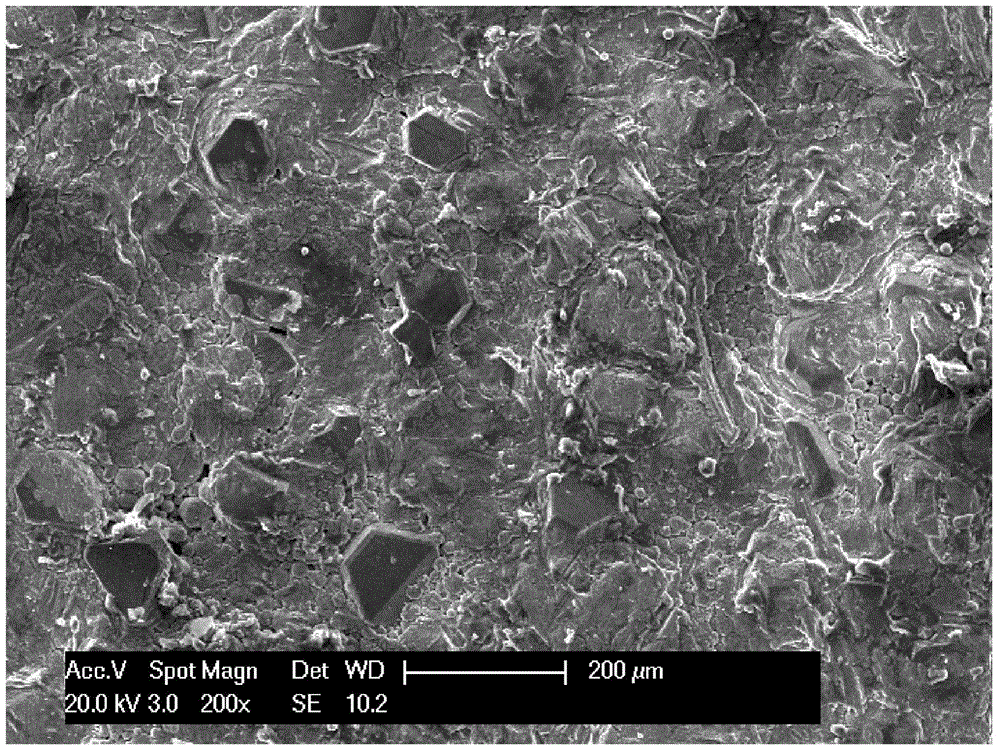

[0034] Put Ti-coated diamond particles (particle size: 104-124 μm) with a volume fraction of 45% and aluminum powder (nitrogen atomization, particle size: 20-30 μm) with a volume fraction of 55% on a three-dimensional planetary mixer for 6 hours . The diamond-Al composite powder was cold-pressed under a hydraulic press with a pressing pressure of 200 MPa to obtain a diamond-Al powder compact with a diameter of 20 mm. Aluminum foils with a diameter of 20 mm and a thickness of 400 μm were cut, respectively placed on the upper and lower surfaces of the compact, and molded. Sinter the compact in a vacuum hot-press furnace at a temperature of 650°C, a sintering pressure of 50 MPa, and a vacuum degree of 10 -3 Pa, holding time 90min, obtain sandwich structure diamond-Al composite material (such as Figure 4Shown), the measured thermal conductivity is 467W / m·K. The surface of the sandwich structure is polished with 800 and 1200 mesh sandpaper, and the thickness of the residual alu...

Embodiment 2

[0036] Put Ti-coated diamond particles (particle size: 89-104 μm) with a volume fraction of 50% and aluminum powder (nitrogen atomization, particle size: 20-30 μm) with a volume fraction of 50% on a three-dimensional planetary mixer for 6 hours . The diamond-Al composite powder was cold-pressed under a hydraulic press with a pressing pressure of 200 MPa to obtain a diamond-Al powder compact with a diameter of 20 mm. Aluminum foils with a diameter of 20 mm and a thickness of 150 μm were cut, respectively placed on the upper and lower surfaces of the compact, and molded. Sinter the compact in a vacuum hot-press furnace at a temperature of 640°C, a sintering pressure of 70MPa, and a vacuum degree of 10 -3 Pa, the holding time is 60min, and the sandwich structure diamond-Al composite material is obtained after cooling, and the measured thermal conductivity is 424W / m·K. The surface of the sandwich structure is polished with 800 and 1200 mesh sandpaper, and the thickness of the re...

Embodiment 3

[0038] Put Ti-coated diamond particles (particle size: 150-178 μm) with a volume fraction of 55% and aluminum powder (nitrogen atomization, particle size: 20-30 μm) with a volume fraction of 45% on a three-dimensional planetary mixer for 6 hours . The diamond-Al composite powder was cold-pressed under a hydraulic press with a pressing pressure of 200 MPa to obtain a diamond-Al powder compact with a diameter of 20 mm. Aluminum foils with a diameter of 20 mm and a thickness of 200 μm were cut, respectively placed on the upper and lower surfaces of the compact, and molded. Sinter the above compact in a vacuum hot press furnace at a temperature of 650°C, a sintering pressure of 30MPa, and a vacuum degree of 10 -3 Pa, the holding time is 120min, and the sandwich structure diamond-Al composite material is obtained after cooling, and the measured thermal conductivity is 448W / m·K. The surface of the sandwich structure is polished with 800 and 1200 mesh sandpaper, and the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com