Special mineral magnetic separator conveying belt composite material and manufacturing method thereof

A technology of composite materials and magnetic separators, applied in conveyors, chemical instruments and methods, transportation and packaging, etc., can solve the problems of rough surface, low tensile strength, affecting mineral screening, etc., and achieve low friction coefficient and flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

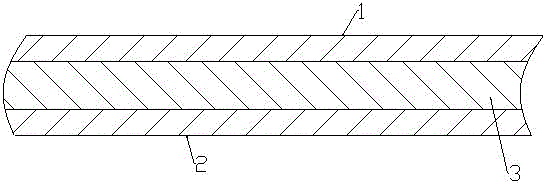

[0026] see figure 1 , a special conveyor belt composite material for mineral magnetic separators, including an upper surface layer, a lower surface layer and a sandwich layer. The upper surface layer is a polytetrafluoroethylene layer, the lower surface layer is a rubber layer, and the sandwich layer is an aramid fiber layer. The aramid fiber layer is It is a network structure woven by several aramid fiber filaments in a certain order, and its strength is greater than the modulus of 25 g / denier.

[0027] The said aramid fiber layer is formed by laminating and weaving one or more layers of aramid fiber network structure.

[0028] The aramid fibers are para-aramid fibers and meta-aramid fibers.

[0029] The para-aramid fibers may be all-para-ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com