A micro-scale dynamic dispersion glue

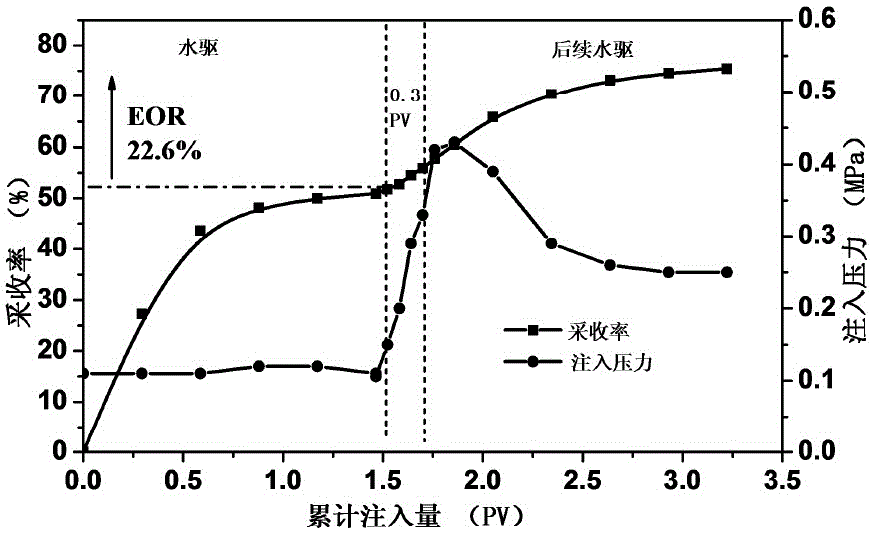

A dispersant and micro-scale technology, which is applied in the field of nano-micro materials and oilfield chemistry, can solve the problems that polymers cannot form colloidal dispersants, difficult gelation, poor adaptability, etc., and achieve excellent long-term stability and extended water flooding Excellent effect on sweep coefficient and erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 each component weight ratio is:

[0031] 1. Main agent hyperbranched polymer: 0.075% to 0.175%,

[0032] 2. Cross-linking agent citrate: 0.005% to 0.0125%,

[0033] 3. Cross-linking agent aluminum trichloride: 0.0075% to 0.0175%,

[0034] 4. Stabilizer sulfite: 0.005% to 0.01%,

[0035] 5. The rest is water.

[0036] The hyperbranched polymer mother liquor with a mass concentration of 0.5% was prepared with suction-filtered oilfield injection water (see Table 1 for the ion composition), and was left to stand for 24 hours before use. Distilled water was used to prepare 1.0% lemon salt solution, 1.0% aluminum chloride solution and 1.0% sulfite solution respectively. Add a certain amount of 0.5% hyperbranched polymer mother liquor, 1.0% lemon salt solution, 1.0% aluminum chloride solution, and 1.0% sulfite to a 120ml jar according to the set system concentration solution, add quantitative oil field injection water, and prepare 100ml of micro-scale dynamic...

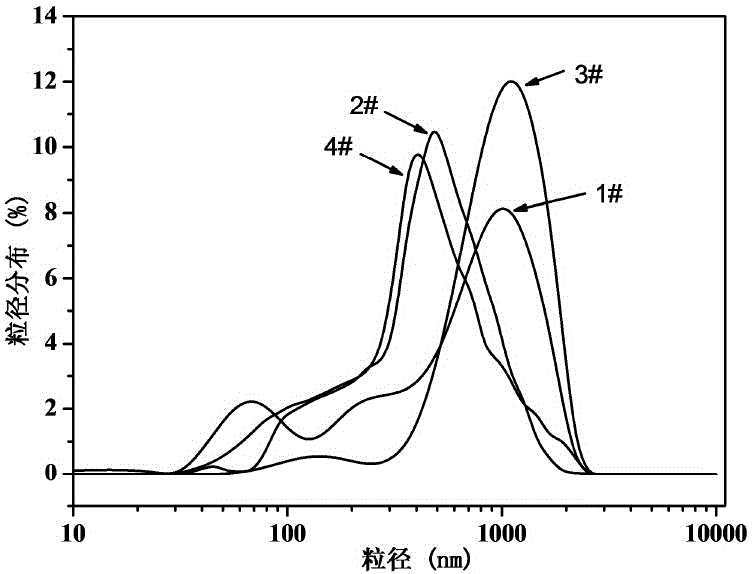

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com