Waste heat recycling air preheating bypass coal saving system and application thereof

A technology of air preheating and waste heat recovery, applied in the direction of reducing greenhouse gases, climate sustainability, lighting and heating equipment, etc., can solve the problem that the repair effect is difficult to achieve the ideal effect, affect the continuous production requirements of enterprises, tube sheets or welds No leakage and other problems, to achieve the effect of no safety hazard, simple and convenient operation, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

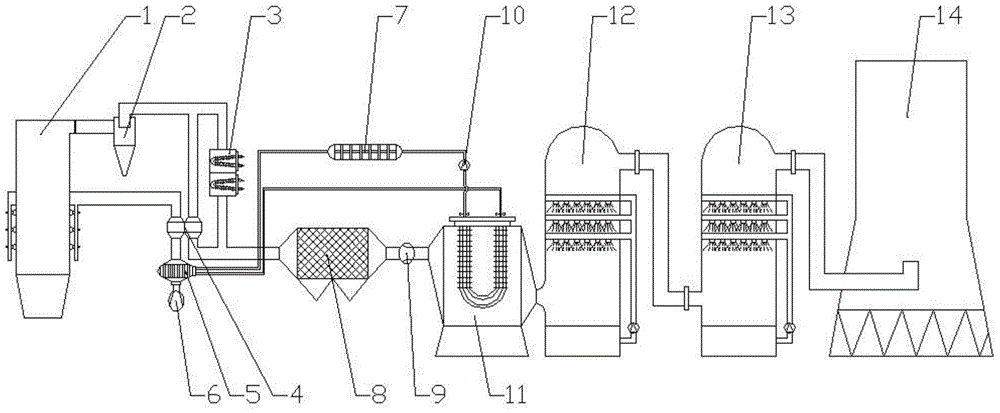

[0026] This embodiment provides a waste heat recovery air preheating bypass coal-saving system, the structure is as follows figure 1 As shown, it includes a boiler 1, a spray tower and a cooling tower 14. The exhaust gas outlet of the boiler 1 is connected to the air inlet of the cyclone dust collector 2, and the gas outlet of the cyclone dust collector 2 is connected to the heat pipe of the heat exchanger 4, and the cyclone dust collector 2 The outlet of the outlet is provided with a branch to connect the decompression device 3, and the decompression device 3 is connected in series with the heat pipe of the heat exchanger 4;

[0027] The heat pipe outlet of the heat exchanger 4 is connected to the air inlet of the electrostatic precipitator 8, and the air outlet of the electrostatic precipitator 8 is provided with a second fan 9, and the air outlet of the second fan 9 is connected to the exhaust gas cooler 11, and the upper end of the exhaust gas cooler 11 is There are two ci...

Embodiment 2

[0037] This embodiment provides a waste heat recovery air preheating bypass coal-saving system, the structure is as follows figure 1 As shown, it includes a boiler 1, a spray tower and a cooling tower 14. The exhaust gas outlet of the boiler 1 is connected to the air inlet of the cyclone dust collector 2, and the gas outlet of the cyclone dust collector 2 is connected to the heat pipe of the heat exchanger 4, and the cyclone dust collector 2 The outlet of the outlet is provided with a branch to connect the decompression device 3, and the decompression device 3 is connected in series with the heat pipe of the heat exchanger 4;

[0038] The heat pipe outlet of the heat exchanger 4 is connected to the air inlet of the electrostatic precipitator 8, and the air outlet of the electrostatic precipitator 8 is provided with a second fan 9, and the air outlet of the second fan 9 is connected to the exhaust gas cooler 11, and the upper end of the exhaust gas cooler 11 is There are two circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com