A kind of lithium-ion battery solid electrolyte membrane and preparation method thereof

A solid electrolyte membrane and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of reducing cell capacity, low-temperature performance and rate performance, and increasing ion transmission resistance, so as to reduce ion transmission resistance and speed up ion transmission. , the effect of shortening the resting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

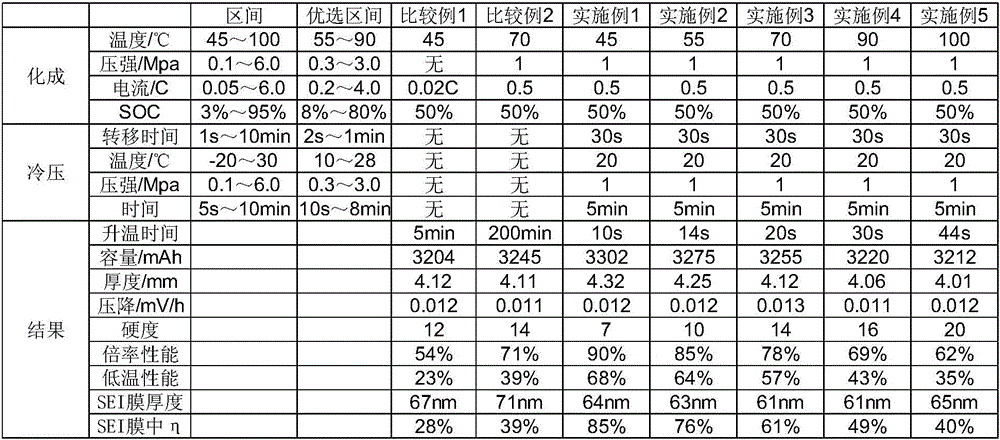

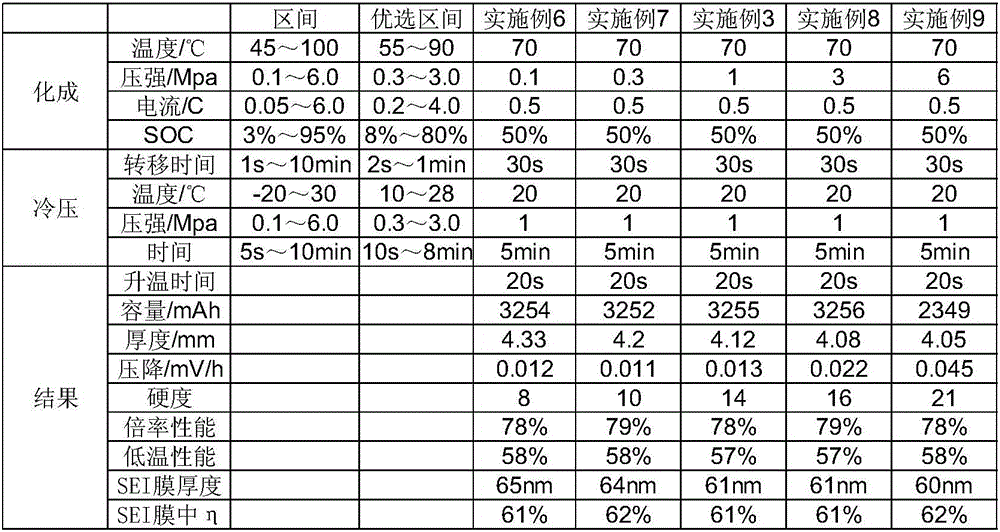

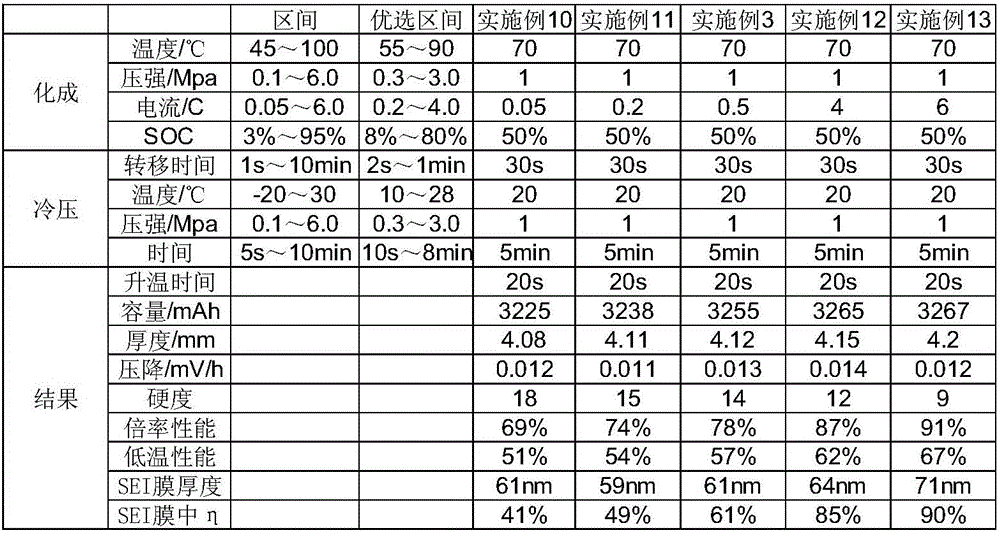

Examples

preparation example Construction

[0030] The preparation of the negative electrode sheet: the negative electrode slurry (negative electrode active material: binder: conductive agent is mixed in deionized water according to the ratio of mass ratio: 92:3:5) is coated on the negative electrode current collector, then dried, and then After cold pressing, slitting, and welding the negative tabs, the negative electrode sheet is prepared for use.

[0031] Preparation of the positive electrode sheet: the positive electrode slurry (positive electrode active material: binder: conductive agent is mixed in NMP according to the ratio of mass ratio: 93:2:5) is coated on the positive electrode current collector, then dried, and then passed After cold pressing, slitting, and welding the positive tabs, the positive electrode sheet is prepared for use.

[0032] Preparation of cells to be formed: Assemble the prepared positive electrode sheet, negative electrode sheet, and separator into a bare cell, then place it in an aluminum...

Embodiment 1

[0038] Put the cell to be formed into a hot-pressed forming fixture at a temperature of 45°C, and after applying a surface pressure of 1MPa, record the time for the cell to heat up to 45°C; then use a current of 0.5C to charge the cell to 50% SOC , after the completion of the formation, transfer the cell to a cold-pressing fixture within 30s for cold-pressing the cell. The cold-pressing temperature is 20°C, the pressure is 1MPa, and the time is 5min. Afterwards, the pressure of the cold pressing fixture is released to obtain the degassed cell.

Embodiment 2

[0040] Except following difference with embodiment 1, all the other are identical with embodiment 1:

[0041] Put the cell before formation into a hot-pressing fixture at a temperature of 55°C, and record the time required for the cell to heat up to 55°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com