Screen protecting film for electronic product

A technology for electronic products and protective films, applied in the field of shielding protective films for electronic products, can solve the problems of metal sheet or mesh weight, labor and time, human health hazards, etc. The effect of wave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

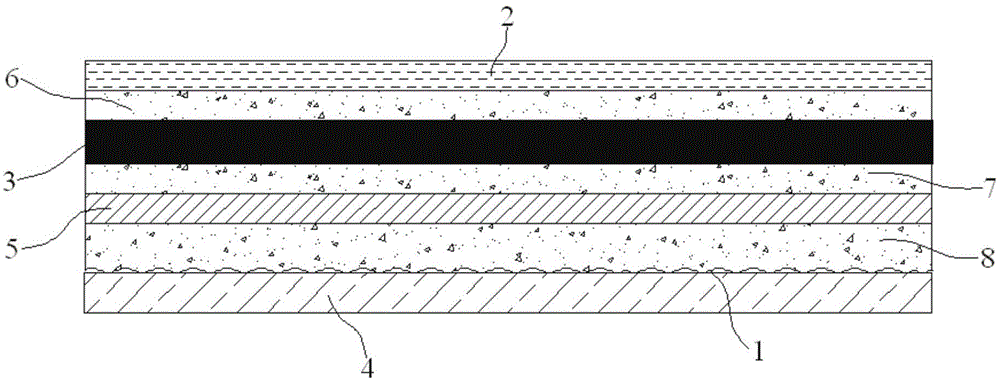

[0033] Embodiments 1 to 4: A shielding protective film for electronic products, comprising a metal layer 2, a wave-absorbing layer 3 and a release material layer 4; a first adhesive layer 5 is arranged between the PET insulating layer 1 and the metal layer 2, A second adhesive layer 6 is provided between the metal layer 2 and the wave-absorbing layer 3; a third adhesive layer 7 and a polypropylene film layer 5 are sequentially provided between the wave-absorbing layer 3 and the release material layer 4 And the fourth adhesive layer 8 ; the surface of the fourth adhesive layer 8 in contact with the release material layer 4 has several bumps 1 .

[0034] The components and contents of the absorbing layer 3 are as shown in Table 1:

[0035] Table 1

[0036] Example 1 Example 2 Example 3 Example 4 100 parts of absorbing powder 100 copies 100 copies 100 copies 100 copies 25~35 parts of butyl acrylate 25 copies 32 copies 30 copies 28 cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com