Solid-phase synthesis method for nano silicon dioxide particles based on histidine tag

A nano-silica and histidine-labeled technology, which is applied in the direction of silica, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of difficult separation and purification, difficult sample recovery, etc., and achieve convenient purification , The effect of simplifying the preparation process and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

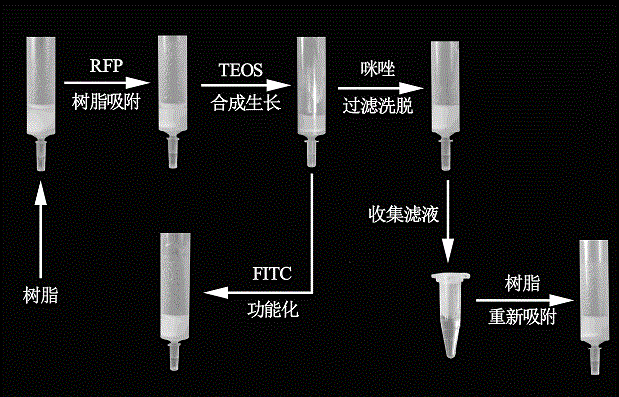

[0024] Example 1: Preparation of red fluorescent protein (RFP) nano-silica particles based on histidine tag

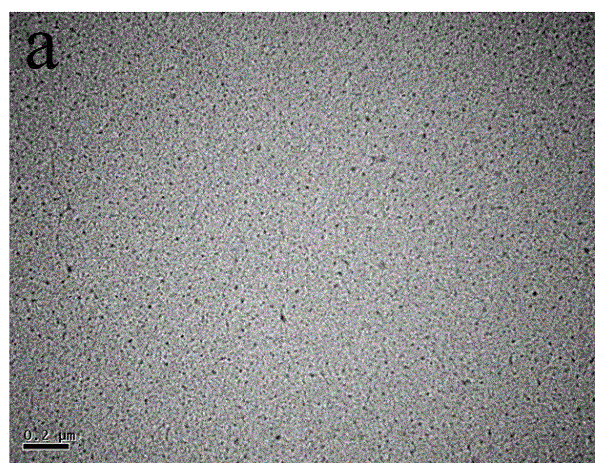

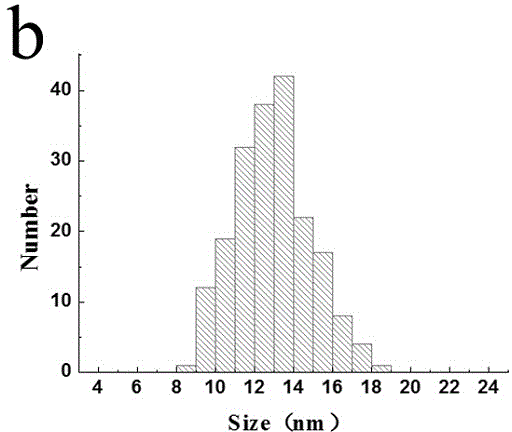

[0025] First, resin particles containing nickel ions on the surface and red fluorescent protein based on histidine tag (can be replaced by green fluorescent protein GFP, near-infrared fluorescent protein IFP, yellow fluorescent protein YFP, cyan fluorescent protein CFP and other histidine-labeled protein, etc.) according to 0.05-0.25mg protein / mg resin particles into the phosphate buffer solution of pH = 7.0-8.0, stirred to make it fully mixed and then added to the gravity settling column with filter membrane. Add (3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) in a mass ratio of 1:2-5:2 for deionization In water, shake briefly and add to the gravity column, shake for 30-60min to complete the activation of the red fluorescent protein surface. Add 5-10 μL of 3-aminopropyltriethoxysilane, shake fully to dissolve it, react f...

Embodiment 2

[0027] Example 2: Further functionalization of red fluorescent protein (RFP) nano-silica particles based on histidine tag

[0028] The surface of the nano-silica particles re-adsorbed by the resin particles in Example 1 can be further functionalized according to the requirements: add 5-10 μL of 3-aminopropyltriethoxysilane, shake it fully to dissolve it, and react 12- After 16 hours, rinse the gravity column with deionized water to remove incompletely reacted cross-linking agent and reaction by-products. After that, 0.01-0.02mM FITC was added, and after fully shaking, it was placed in a shaker and shaken at a constant speed for 8-12h. Rinse the column again with deionized water to remove incompletely reacted FITC. After a simple elution process and removal of imidazole in the solution, the FITC-labeled nano-silica particles were obtained.

Embodiment 3

[0029] Example 3: Preparation of catalase nano-silica particles based on histidine tag

[0030]First, add the resin particles containing nickel ions on the surface and the catalase based on histidine tag into the phosphate buffer solution with pH=7.0-8.0 according to 0.05-0.5 mg enzyme / mg resin particles, stir to make them fully mixed and then add to Gravity settling column with filter membrane. According to the preparation method in Example 1, it is possible to obtain silica-coated catalase nanoparticles with an average particle size of 20nm, uniform particle size, and good dispersion, and the activity of catalase encapsulated by silica It can still maintain more than 90% of the original activity, and has more excellent stability. At the same time, the histidine tag on the surface of the nanoparticles enables it to be recycled many times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com