Secondary pyrolysis and waste heat recycling system for biomass pyrolysis gas

A biomass pyrolysis and secondary high temperature technology, which is used in the catalytic conversion of impurities, gas purification, gas dust removal, climate sustainability, etc. and other problems, to achieve the effect of improving the purification effect and energy utilization efficiency, increasing the applicability, and facilitating adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

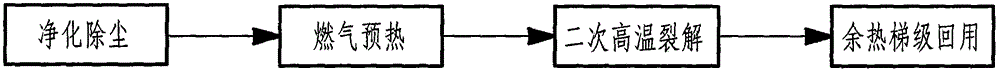

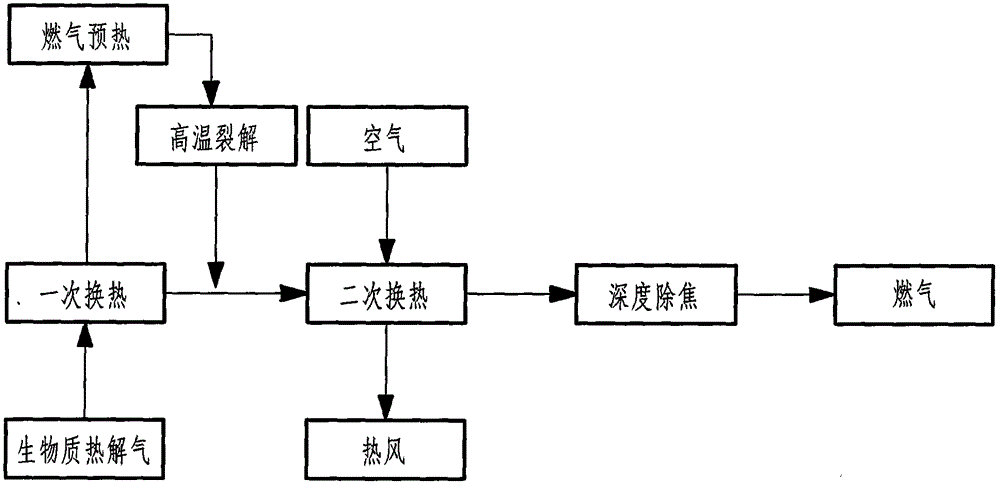

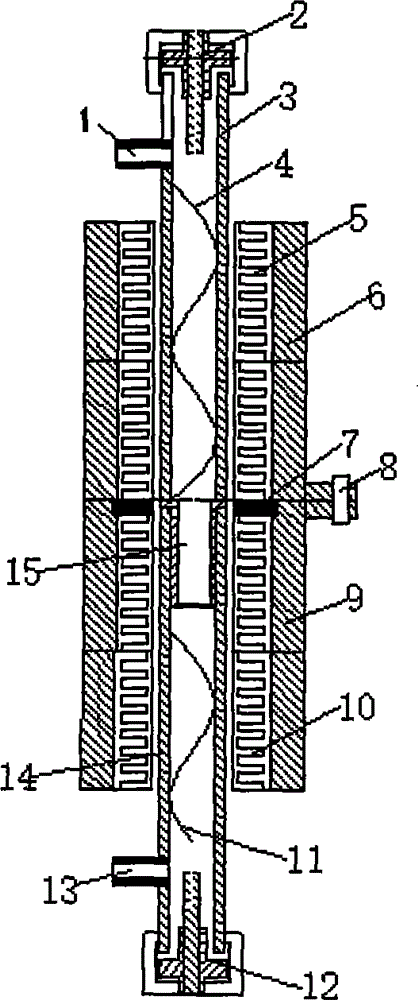

[0032] This embodiment is a small-scale production system of biomass pyrolysis gas and carbon co-production. The following describes the embodiment of the present invention in conjunction with the accompanying drawings: the production system performs secondary high-temperature cracking and waste heat recovery on biomass pyrolysis gas, including heat It is composed of degassing purification and dust removal, gas preheating, secondary pyrolysis and waste heat cascade reuse process. The secondary pyrolysis process is the core of the system. The waste heat cascade reuse includes a two-stage heat exchange system, which can realize the efficient utilization of waste heat. The specific steps include: a) purification and dust removal, the high-temperature pyrolysis gas generated after biomass pyrolysis is firstly subjected to dust removal and purification; b) gas preheating, preheating the pyrolysis gas generated by biomass pyrolysis, so that the pyrolysis gas After reaching the high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com