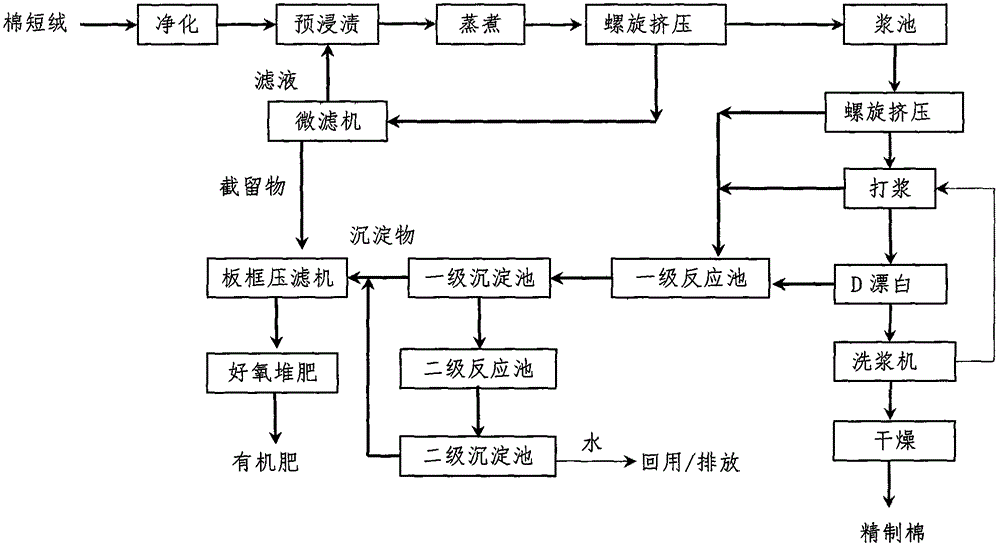

Refined cotton production and pollutant treatment method

A technology for pollutants and refined cotton, applied in pulping, papermaking or textile fields, can solve the problems of biochemical water treatment system impact, treatment efficiency discount, difficulty in emission standards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A method for preparing refined cotton and its pollutant treatment

[0027] (1) Deep purification of cotton linters

[0028]Using a mechanical disintegrator, the cotton linters, cottonseed husks, cotton boll shells, sand and dust are peeled off from each other, screened by a vibrating screen with a sieve hole of 0.5 cm, and the heavy impurities with a particle size of less than 0.5 cm are screened and removed. It is sent to the vibrating corrugated conveyor belt with a wind hood. The corrugated depth of the corrugated conveyor belt is 1cm, the width is 0.5cm, and the amplitude is 2-3cm; the cottonseed husk, boll shell and sand that have not been removed by the vibrating screen will gather in The corrugated material of the corrugated conveyor belt is sent to the heavy miscellaneous collection bin, and the dust will be collected by the upper wind hood during the vibration process.

[0029] It can effectively reduce the ash content of cotton linters, cotton seed hulls and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com