Preparation method of in-situ calcium silicate fiber pulp and calcium silicate high-filler pulp

A calcium silicate and pulp technology, applied in the field of filler filling, can solve the problems of low filler retention rate, high chemical consumption, poor binding force between calcium silicate and fiber, etc., achieving wide source of raw materials and improving bonding strength , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

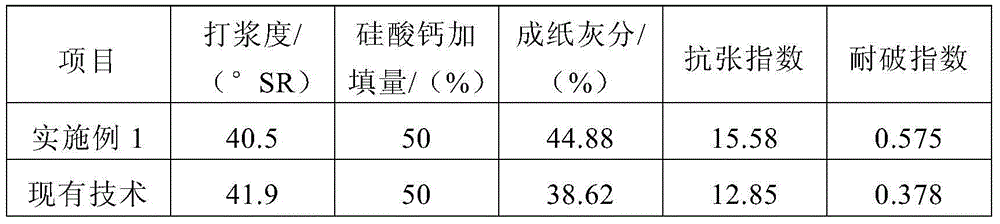

Embodiment 1

[0025] Add 20g of fly ash to 250g of sodium hydroxide solution with a concentration of 16%. At this time, the dry basis mass ratio of fly ash and sodium hydroxide is 0.50:1. After stirring, a slurry is formed, and the temperature of the slurry is raised to 120°C , desiliconization reaction under this condition for 2 hours, after the reaction, the desiliconization slurry was separated from the solid and liquid, and the separated desilication filtrate was finely filtered through a leaf filter to obtain a desiliconization solution, which was diluted to 0.123L. At this time, the SiO in the desiliconization solution 2 Concentration is 59.8g / L, it is used as the siliceous raw material of fiber in-situ synthesis calcium silicate, measures 160ml diluted desiliconization solution, and adds 20g absolute dry coniferous wood pulp fiber in the desilication solution that vector takes, fully After soaking and standing for 1 hour, use a beater to beat the pulp, and control the beating degree ...

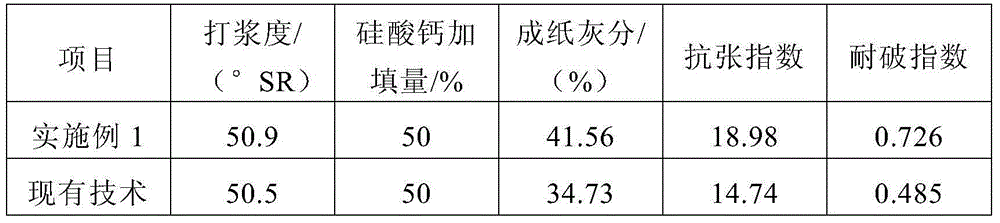

Embodiment 2

[0032] Add 19g of fly ash to 180g concentration of 15% sodium hydroxide solution, form a slurry after stirring, the dry basis mass ratio of fly ash and sodium hydroxide is 0.70:1, the temperature of the slurry is raised to 130°C, Under these conditions, desiliconization takes 2.5 hours. After the reaction, the desiliconization slurry is subjected to solid-liquid separation, and the desilication filtrate after solid-liquid separation is finely filtered through a leaf filter to obtain a desiliconization liquid, which is diluted to 0.14 L, SiO in the desiliconization solution at this time 2 The concentration is 55g / L, measure 170ml of diluted desiliconization solution, add 20g of dry broad-leaved wood pulp fiber, fully soak and let it stand for 1 hour, then use a beater to beat, control the beating degree of pulp at 45°SR~55° In the SR, adjust the pulp concentration of the pulp solution to 2% after beating, add the lime emulsion with a concentration of 150g / L to the pulp solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com