Substrate for inversely installed LED chip and manufacturing method thereof

A technology of LED chip and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that the quantum efficiency in the LED chip cannot be fully exerted, destroy the light output effect of the flip-chip LED chip, and reduce the light output efficiency, etc., so as to avoid Lithographic alignment is difficult, suitable for large-scale commercial production, and the effect of improving internal quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

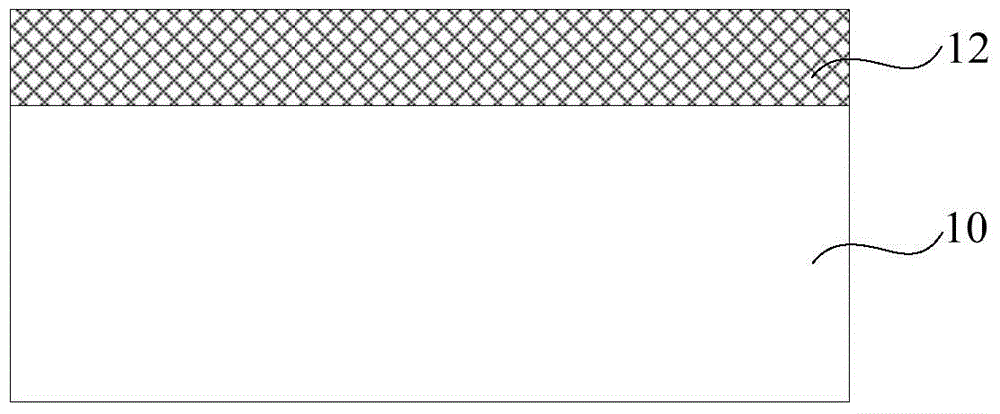

[0067] Figure 10 It is a top view of a substrate for flip-chip LED chips according to Embodiment 1 of the present invention, Figure 9 yes Figure 10 Schematic cross-sectional view of the structure shown along the direction AA'. Such as Figure 9-10 As shown, the substrate for a flip-chip LED chip includes: a support substrate 10, a lattice matching layer 11 having the same crystal structure as the epitaxial layer of the flip-chip LED chip, and a dielectric layer 12, wherein the dielectric layer 12 is a columnar structure arranged in an array, the lattice matching layer 11 is formed on the support substrate 10 , and the columnar structure is embedded in the lattice matching layer 11 .

[0068] Wherein, the columnar structure may be a columnar structure, an elliptical columnar structure, or a polygonal columnar structure. In this embodiment, the columnar structure is a hexagonal columnar structure. Of course, since the supporting substrate 10 is a circular substrate, the ...

Embodiment 2

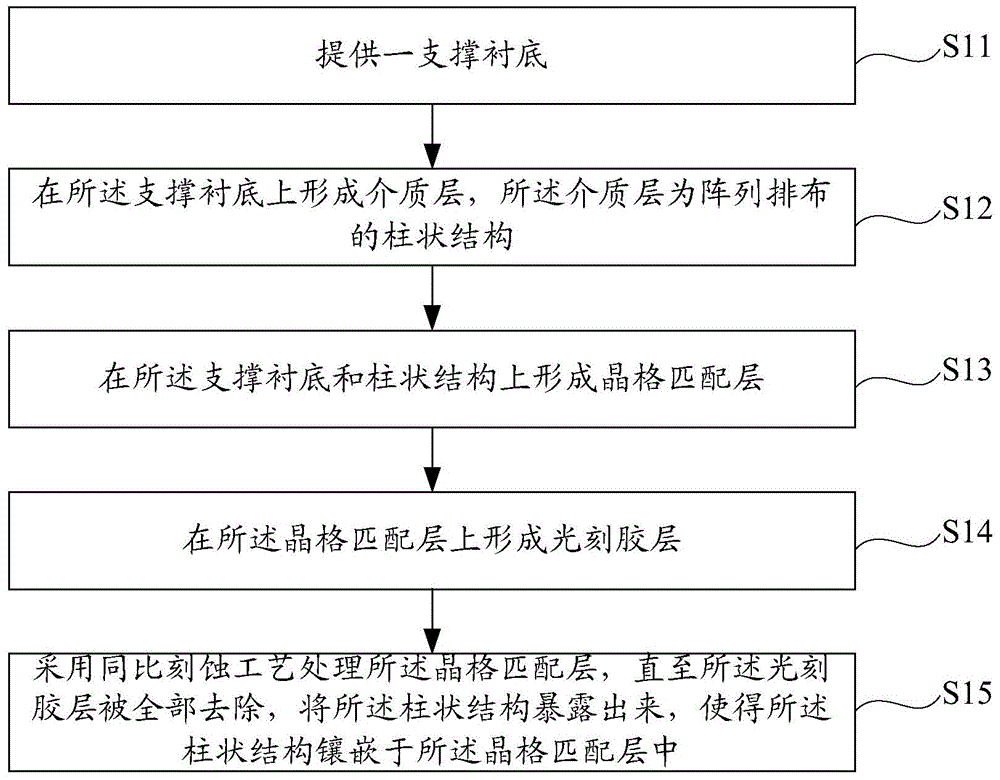

[0090] The structure of the substrate for flip-chip LED chips in this embodiment is the same as that of Embodiment 1, but the manufacturing method adopted in this embodiment is different, such as Figure 11 As shown, the manufacturing method for the substrate of the flip-chip LED chip provided by the present invention comprises the following steps:

[0091] S21: providing a supporting substrate;

[0092] S22: forming a lattice matching layer on the support substrate, the lattice matching layer having columnar holes arranged in an array;

[0093] S23: forming a dielectric layer on the support substrate and the lattice matching layer;

[0094] S24: forming a photoresist layer on the dielectric layer;

[0095] S25: performing a backlighting and developing process on the support substrate, and removing the photoresist layer directly above the lattice matching layer;

[0096] S26: Etching and removing the dielectric layer directly above the lattice matching layer to form a colum...

Embodiment 3

[0109] The difference between the substrate for flip-chip LED chips in this embodiment and the first embodiment is that the lattice matching layer 11 is a columnar structure, and the dielectric layer 12 is formed on the supporting substrate 10, so The dielectric layer 12 has columnar holes arranged in an array, and the lattice matching layer 11 is embedded in the dielectric layer 10 through the columnar holes.

[0110] Figure 30 It is a top view of a substrate for flip-chip LED chips according to Embodiment 3 of the present invention, Figure 29 yes Figure 30 Schematic cross-sectional view of the structure shown along the direction AA'. Such as Figures 29-30 As shown, the substrate for the flip-chip LED chip includes: a support substrate 10, a lattice matching layer 11 having the same crystal structure as the epitaxial layer of the flip-chip LED chip, and a dielectric layer 12, wherein the lattice The matching layer 11 is a columnar structure arranged in an array, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com