Preparation method of banana-goat milk composite yoghourt

A technology of compounding goat lactic acid and banana, applied in dairy products, milk preparations, applications, etc., can solve the problem of goat milk and sheep having a strong smell, and achieve the effect of solving the waste of fruit resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

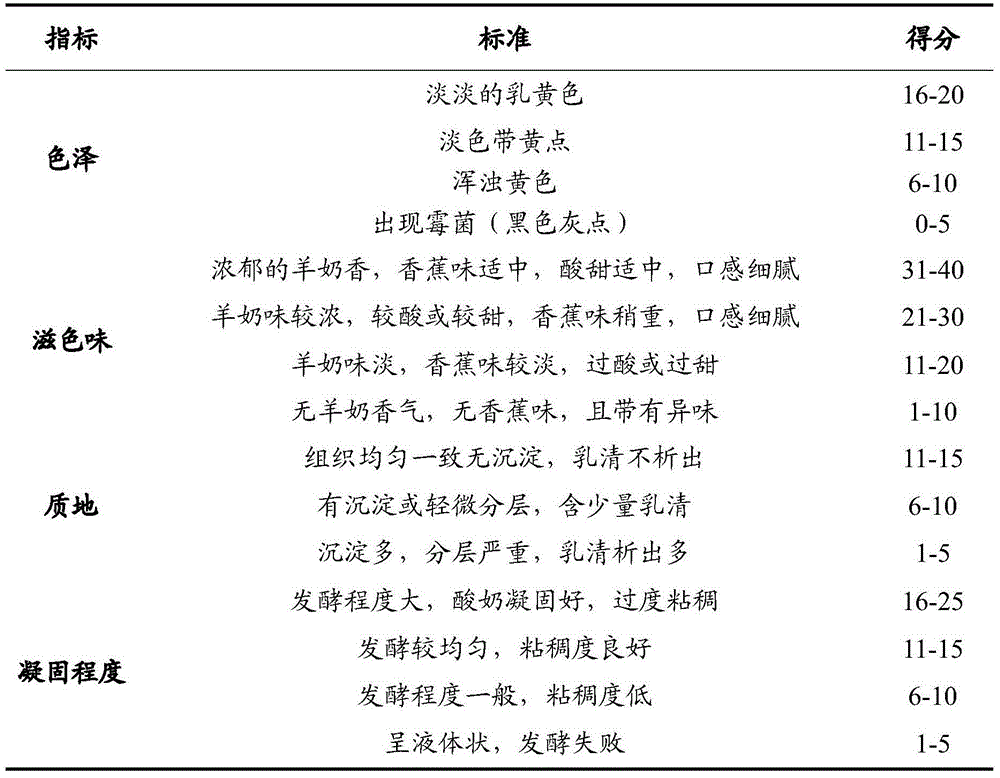

Examples

preparation example Construction

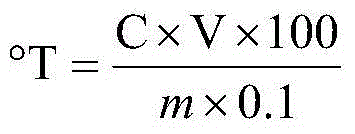

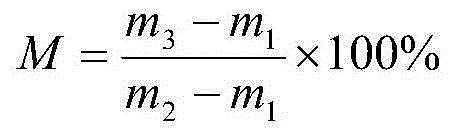

[0025] The invention provides a method for preparing banana compound goat's milk yoghurt, which is specifically implemented according to the following steps:

[0026] Step 1, the preparation of banana pulp, select eight or nine ripe, fresh, undamaged bananas. Peel the banana and cut it open, scrape off the core containing black silk, immerse in boiling water and blanch for 3-8 minutes, add 0.5% citric acid and vitamin C in total according to the weight of the banana pulp to protect the color, citric acid and vitamin C The mass ratio of banana pulp is 2:1; add water to make banana pulp, wherein, the solid-liquid ratio of banana pulp to water (g.mL -1 ) at a ratio of 1:6, heat and sterilize the banana pulp in a water bath at 75°C-85°C for 3min-8min, and filter it with two layers of gauze for subsequent use;

[0027] Step 2. Preparation of goat milk reconstituted milk. Select high-quality and standard goat milk powder, mix goat milk powder with purified water, dissolve goat milk...

Embodiment 1

[0097] A method for preparing banana compound goat's milk yoghurt, which is specifically implemented according to the following steps: select eight or nine ripe, fresh, and undamaged bananas. Peel the banana and cut it open, scrape off the core containing the black silk, immerse in boiling water for 5 minutes, add a total of 0.5% citric acid and vitamin C to protect the color according to the weight of the banana pulp, and the quality of citric acid and vitamin C The ratio is 2:1; add water to make banana pulp, wherein, the solid-liquid ratio of banana pulp to water (g.mL -1 ) at a ratio of 1:6, heat and sterilize the banana pulp in a water bath at 80°C for 5 minutes, and filter it with two layers of gauze to prepare the banana pulp for later use. Select high-quality, standard goat milk powder, mix goat milk powder with purified water, dissolve goat milk powder in water and heat to kill pathogenic bacteria and some harmful microorganisms remaining in goat milk. During the hea...

Embodiment 2

[0099] A method for preparing banana compound goat's milk yoghurt, which is specifically implemented according to the following steps: select eight or nine ripe, fresh, and undamaged bananas. Peel the banana and cut it open, scrape off the core containing black silk, immerse in boiling water for 3 minutes, add 0.5% citric acid and vitamin C in total to protect the color according to the weight of the banana pulp, and the quality of citric acid and vitamin C The ratio is 2:1; add water to make banana pulp, wherein, the solid-liquid ratio of banana pulp to water (g.mL -1 ) at a ratio of 1:6, heat and sterilize the banana pulp in a water bath at 75°C for 3 minutes, and filter it with two layers of gauze to prepare the banana pulp for later use. Select high-quality, standard goat milk powder, mix goat milk powder with purified water, dissolve goat milk powder in water and heat to kill pathogenic bacteria and some harmful microorganisms remaining in goat milk. During the heating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com