Multifunctional antibacterial haze-prevention self-cleaning macromolecule nano composite material and application thereof

A nanocomposite material, self-cleaning technology, applied in application, bactericide, filtration and separation, etc., can solve the problems of reduced filtration efficiency, inability to clean, repeated use, bacterial growth, etc., to achieve clear structure and functionality, and optimize filtration efficiency and air resistance parameters, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

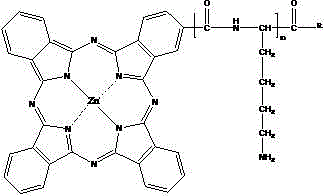

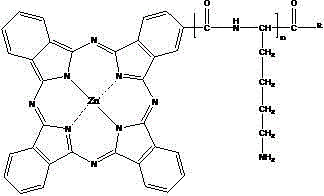

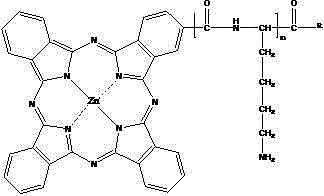

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of multifunctional antibacterial anti-haze self-cleaning macromolecule nanocomposite material, the bamboo fiber non-woven fabric described in table 1 is as base material, the antibacterial agent of certain quality is weighed and cold catalyst and binding agent are mixed according to a certain ratio , using printing and dyeing technology to form an antibacterial self-cleaning polymer composite material, and then form a nanofibrous web through a spinning process on either side of the antibacterial self-cleaning polymer composite material surface to form an antibacterial and anti-haze self-cleaning polymer nanocomposite material. The material contains 0.1mg / m 2 Antimicrobial agent, 0.1 g / m 2 Cold catalyst and 0.1g / m 2 The nanofiber membrane can provide antibacterial effect, anti-smog effect and self-cleaning effect.

Embodiment 2

[0047] The preparation method of multifunctional antibacterial and haze-proof self-cleaning macromolecule nanocomposite material, the cotton fiber non-woven fabric described in Table 1 is used as base material, and the antibacterial agent of certain quality is weighed and mixed with cold catalyst and binder according to a certain ratio , using printing and dyeing technology to form an antibacterial self-cleaning polymer composite material, and then form a nanofibrous web through a spinning process on either side of the antibacterial self-cleaning polymer composite material surface to form an antibacterial and anti-haze self-cleaning polymer nanocomposite material. Material contains 5mg / m 2 Antimicrobial agent, 1 g / m 2 Cold catalyst and 1g / m 2 The nanofiber membrane can provide antibacterial effect, anti-smog effect and self-cleaning effect.

Embodiment 3

[0049] The preparation method of multifunctional antibacterial and haze-proof self-cleaning macromolecule nanocomposite material, the polyethylene terephthalate non-woven fabric described in table 1 is used as base material, takes certain quality antibacterial agent and cold catalyst and bonding The agent is mixed according to a certain ratio, and the printing and dyeing technology is used to form an antibacterial self-cleaning polymer composite material, and then the surface of the antibacterial self-cleaning polymer composite material is thermally fused with the nanofiber net to form an antibacterial and anti-haze self-cleaning polymer nanocomposite material. The composite contains 200mg / m 2 Antibacterial agent, 20g / m 2 Cold catalyst and 50g / m 2 The nanofiber membrane can provide antibacterial effect, anti-smog effect and self-cleaning effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com