Corn bran-based three-dimensional multi-level pore structure carbon material and preparation method thereof

A technology of multi-level pores and carbon materials, applied in chemical instruments and methods, and other chemical processes, can solve problems such as difficult industrialization, high cost, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

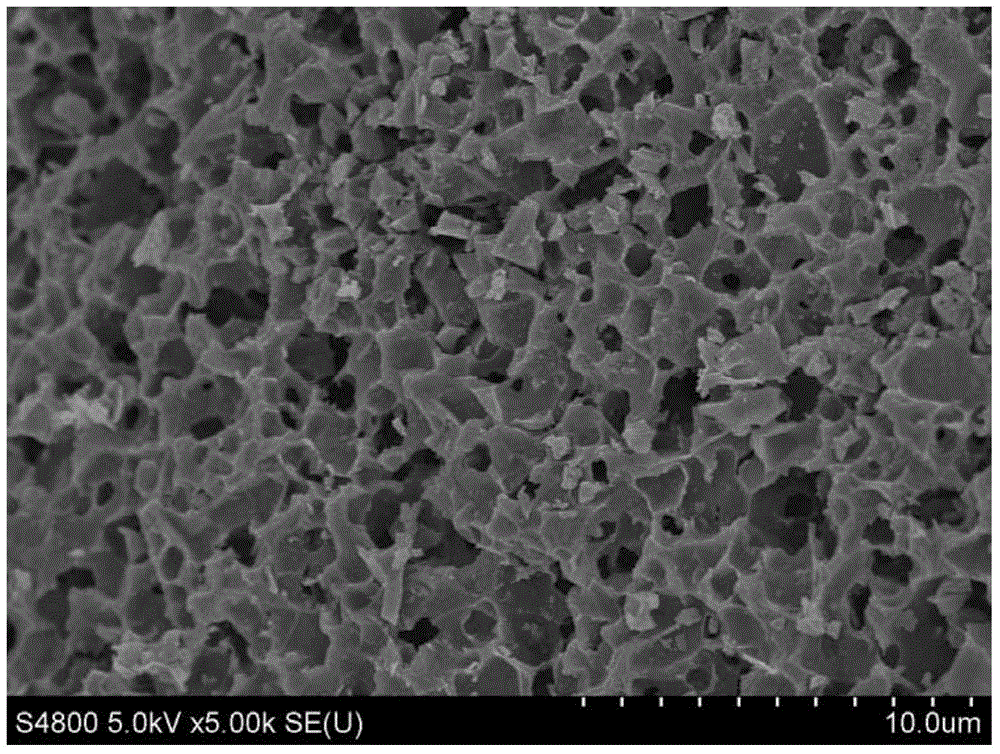

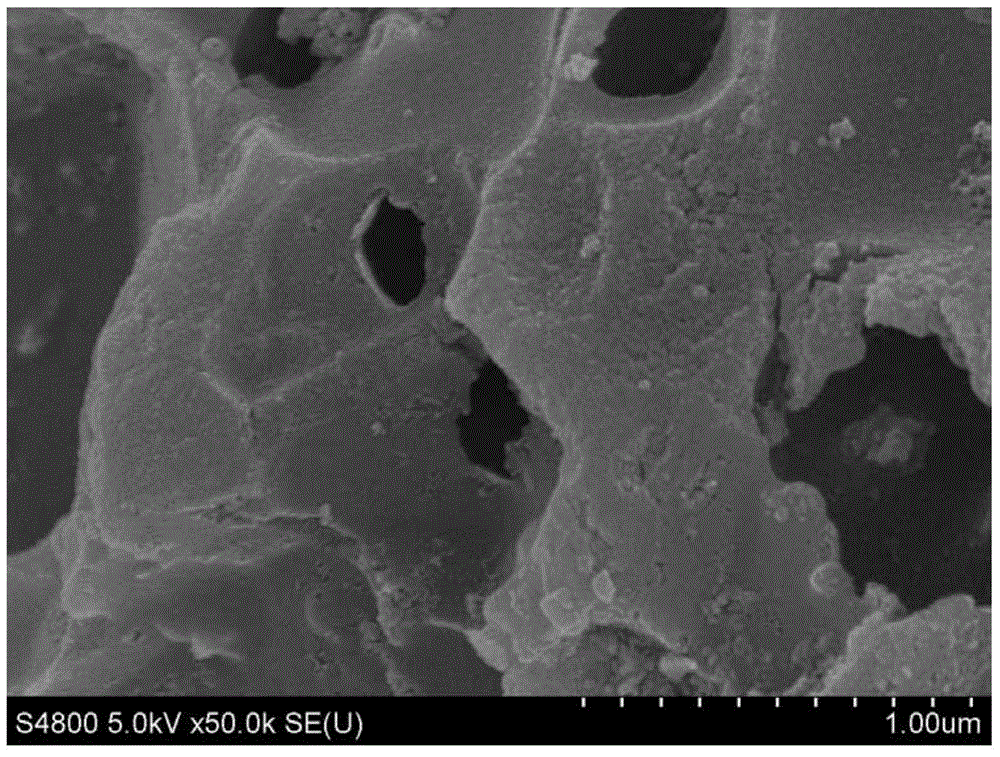

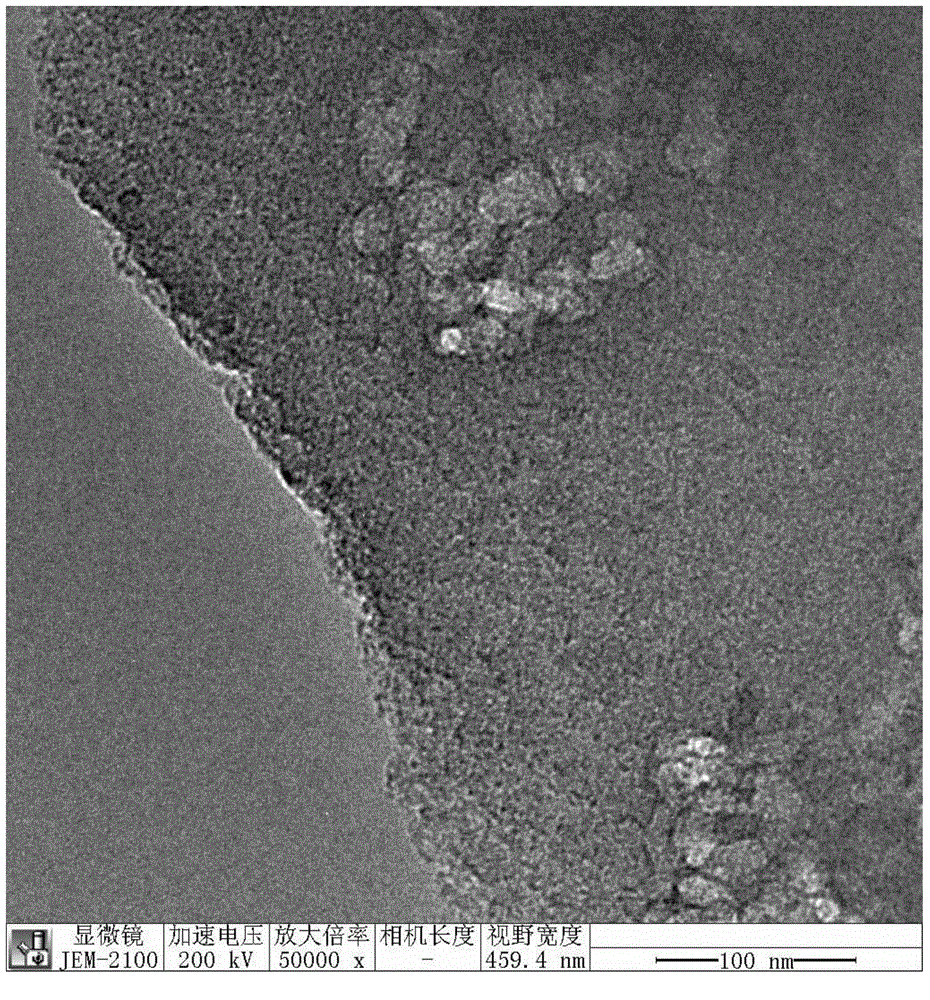

Image

Examples

specific Embodiment approach 1

[0016] Specific implementation mode one: the preparation method of corn bran-based three-dimensional hierarchical porous structure carbon material in this implementation mode is carried out according to the following steps:

[0017] Step 1: Cut corn husks into small pieces, wash with water and dry at 100°C;

[0018] Step 2, adding 5 g of corn husks treated in step 1 into 100 mL of KOH solution with a mass concentration of 5%, then reflux for 4 h in a water bath at 80° C. (obtaining a brown colloidal liquid), filter through a 200-mesh stainless steel sieve after cooling, and leave lower solid;

[0019] Step 3. Dry the solid obtained in step 2 at 100°C and place it in a quartz tube furnace, and then roast it in a high-purity nitrogen (volume fraction: 99.999% pure) atmosphere at a temperature of 800°C for 2 hours (gray solid);

[0020] Step 4: Wash with a hydrochloric acid solution with a concentration of 2 mol / L (to remove potassium salts), centrifuge, wash with water three t...

specific Embodiment approach 2

[0022] Specific implementation mode two: the preparation method of corn bran-based three-dimensional hierarchical porous structure carbon material in this implementation mode is carried out according to the following steps:

[0023] Step 1: Cut corn husks into small pieces, wash with water and dry at 100°C;

[0024] Step 2, adding 5 g of corn husks treated in step 1 into 100 mL of KOH solution with a mass concentration of 7%, then refluxed in a water bath at 80° C. for 4 h (obtaining a brown colloidal liquid), filtered through a 200-mesh stainless steel sieve after cooling, and retained lower solid;

[0025] Step 3. Dry the solid obtained in step 2 at 100° C. and place it in a quartz tube furnace, and roast it for 2 hours at a temperature of 800° C. solid);

[0026] Step 4: Wash with a hydrochloric acid solution with a concentration of 2 mol / L (to remove potassium salts), centrifuge, wash with water three times, and then dry at 120° C. for 12 hours to obtain a corn bran-base...

specific Embodiment approach 3

[0028] Specific implementation mode three: the preparation method of corn bran-based three-dimensional hierarchical porous structure carbon material in this implementation mode is carried out according to the following steps:

[0029] Step 1: Cut corn husks into small pieces, wash with water and dry at 100°C;

[0030] Step 2, adding 5 g of corn husks treated in step 1 into 100 mL of KOH solution with a mass concentration of 9%, then refluxed in a water bath at 80° C. for 4 h (obtaining a brown colloidal liquid), filtered through a 200-mesh stainless steel sieve after cooling, and retained lower solid;

[0031] Step 3. Dry the solid obtained in step 2 at 100° C. and place it in a quartz tube furnace, and roast it for 2 hours at a temperature of 800° C. solid);

[0032] Step 4: Wash with a hydrochloric acid solution with a concentration of 2 mol / L (to remove potassium salts), centrifuge, wash with water three times, and then dry at 120° C. for 12 hours; the cornhusk-based thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com