A method for strengthening the hydrolysis and acidification of chemical wastewater

A technology for hydrolysis and acidification of chemical wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult survival of microorganisms, low efficiency of hydrolysis and acidification, long residence time, etc. , to achieve the effect of being beneficial to hydrolysis and acidification, shortening the residence time, and reducing the amount of alkali addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

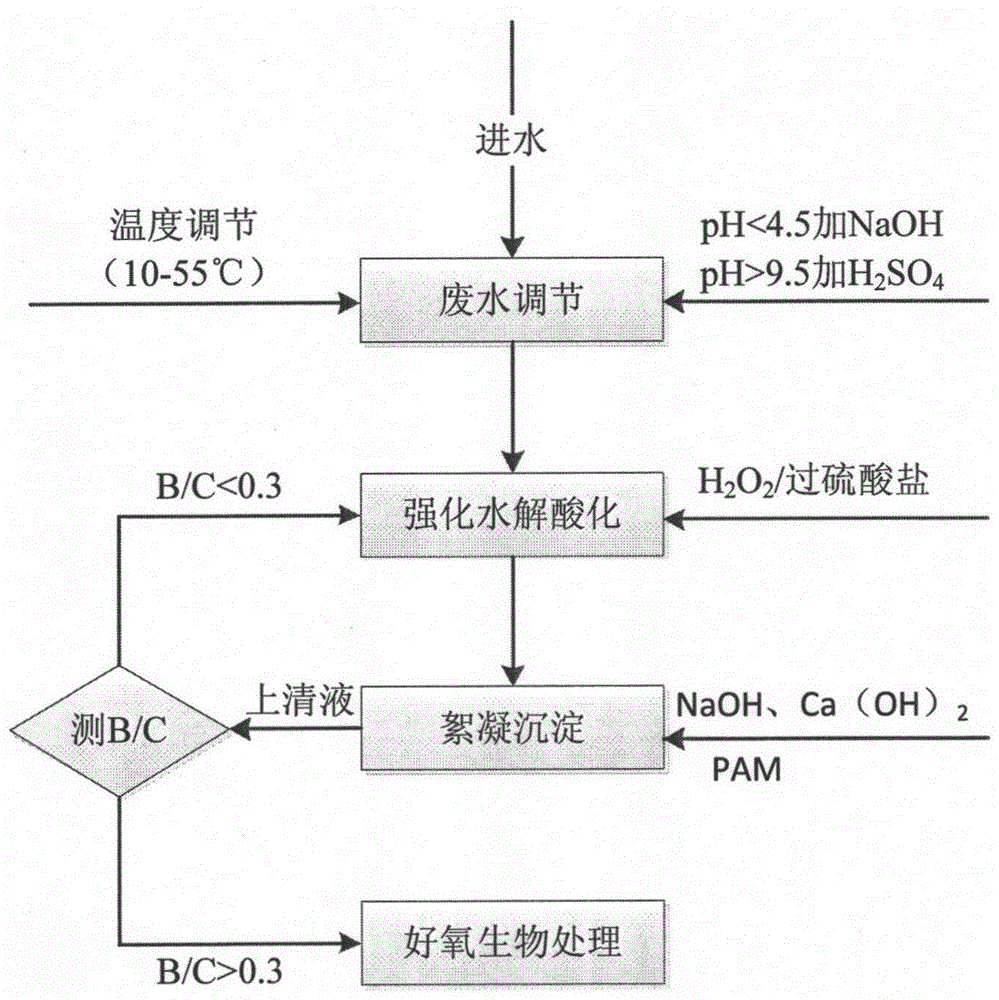

[0037] Such as figure 1 As shown, a method for strengthening the hydrolysis and acidification of chemical wastewater, the specific steps are:

[0038] ①Take 30L of ion exchange resin wastewater (COD is 8067mg / L, B / C is 0.15, pH=8.78) into the adjustment tank, the wastewater pH=8.78 is within the range of 4.5-9.5, no need to adjust the pH, directly inject the hydrolytic acidification bacteria (taken from the secondary sedimentation tank of urban sewage treatment plant) and the enhanced hydrolytic acidification reactor of multi-metal catalytic contact packing, the reinforced hydrolytic acidification packing bag 15kg in the reactor, the hydrolytic acidification bacteria 100g (dry weight) in the reactor, add 30mL H 2 o 2 (30%) solution, add sodium persulfate 5g, under the condition of slight aeration (0.5mg / L) and stirring (250rpm), carry out strengthening hydrolysis acidification reaction, reaction is carried out at 25 ℃.

[0039] ②After 6 hours of first-level enhanced hydrolys...

Embodiment 2

[0044] Such as figure 1 As shown, a method for strengthening the hydrolysis and acidification of chemical wastewater, the specific steps are:

[0045] ①Take 30L of wastewater from a pesticide factory (COD is 15670mg / L, B / C is 0.15, pH is 8.9) into the adjustment tank, the pH of the wastewater is 8.9 within the range of 4.5-9.5, no need to adjust the pH, and it is directly injected with hydrolytic acidification Bacteria (taken from the secondary sedimentation tank of urban sewage treatment plant) and multi-metal catalytic contact packing in the enhanced hydrolytic acidification reactor, the hydrolytic acidification bacteria in the reactor are 100g (dry weight), the enhanced micro-electrolysis filler pack in the reactor is 15kg, and 30mL h 2 o 2 (30%) solution, add sodium persulfate 8g, under the condition of slight aeration (0.8mg / L) and stirring (250rpm), carry out strengthening hydrolysis acidification reaction, reaction is carried out at 25 ℃.

[0046] ②The primary enhanc...

Embodiment 3

[0051] Such as figure 1 As shown, a method for strengthening the hydrolysis and acidification of chemical wastewater, the specific steps are:

[0052] ①Take 30L of wastewater from a printing and dyeing factory (COD is 8560mg / L, B / C is 0.18, pH is 12.75) into the regulating tank, the wastewater pH=12.75 is not within the range of 4.5-9.5, and the concentration is 4mol / l of H 2 SO 4 Adjust the pH to 8.15, and inject the wastewater into the enhanced hydrolytic acidification reactor containing hydrolytic acidification bacteria (taken from the secondary sedimentation tank of the urban sewage treatment plant) and multi-metal catalytic contact packing after adjustment. Endohydrolytic acidification bacteria 100g (dry weight), add 30mL H 2 o 2 (30%) solution, (without adding persulfate), under the conditions of micro-aeration (0.8mg / L) and stirring (250rpm), the enhanced hydrolysis acidification reaction was carried out at 25°C.

[0053] ② First-level enhanced hydrolysis and acidif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com