A copper iodide phosphine complex luminescent material containing cu4i4 cluster core

A technology of luminescent materials and complexes, which is applied in the field of luminescent materials and organic electroluminescent materials, can solve the problems that the luminous intensity cannot meet the application requirements, affect the promotion and application and market performance, and expensive prices, etc., and achieve energy transfer efficiency. Low production cost and the effect of suppressing non-radiative attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of a large number of microcrystalline samples: Weigh 0.3mmol of cuprous iodide and dissolve it in 10mL of acetonitrile to obtain solution A, weigh 0.3mmol of m-anisyl 3 The P ligand was dissolved in 10 mL of dichloromethane to obtain solution B, and solution A and solution B were mixed, and stirred to make the coordination reaction fully occur, and finally the resulting colorless solution was filtered, and all solvents were removed by rotary evaporation, and vacuum-dried. The colorless crystalline powder was obtained as the product, and the yield was 96% (calculated as Cu).

Embodiment 2

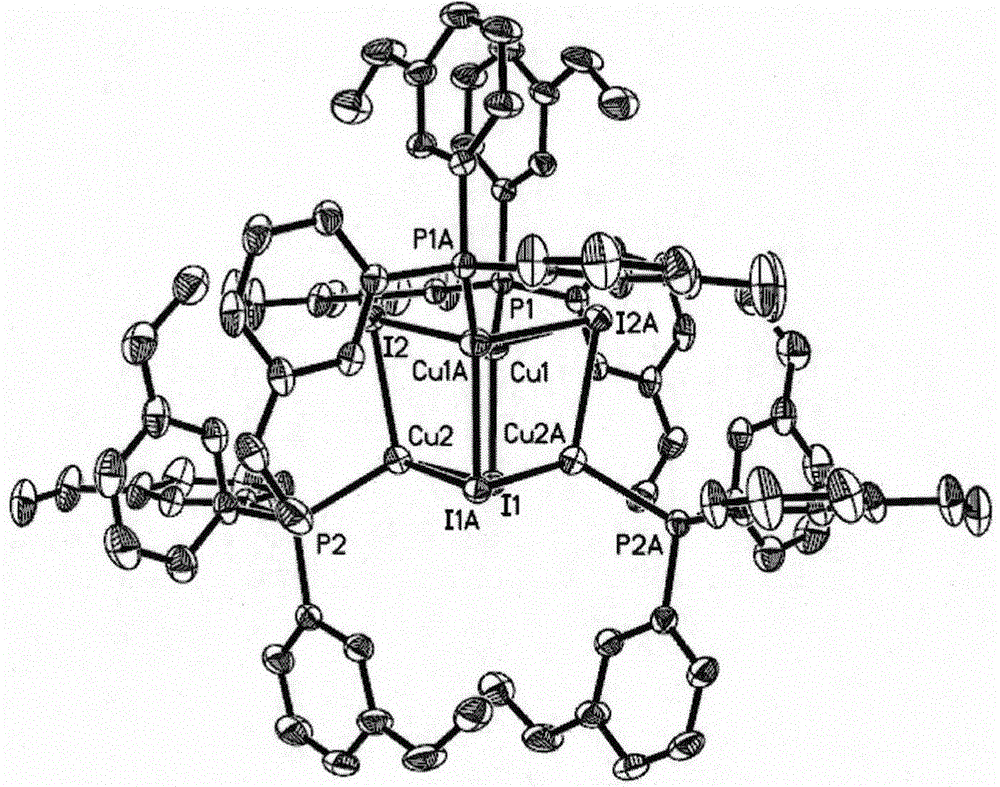

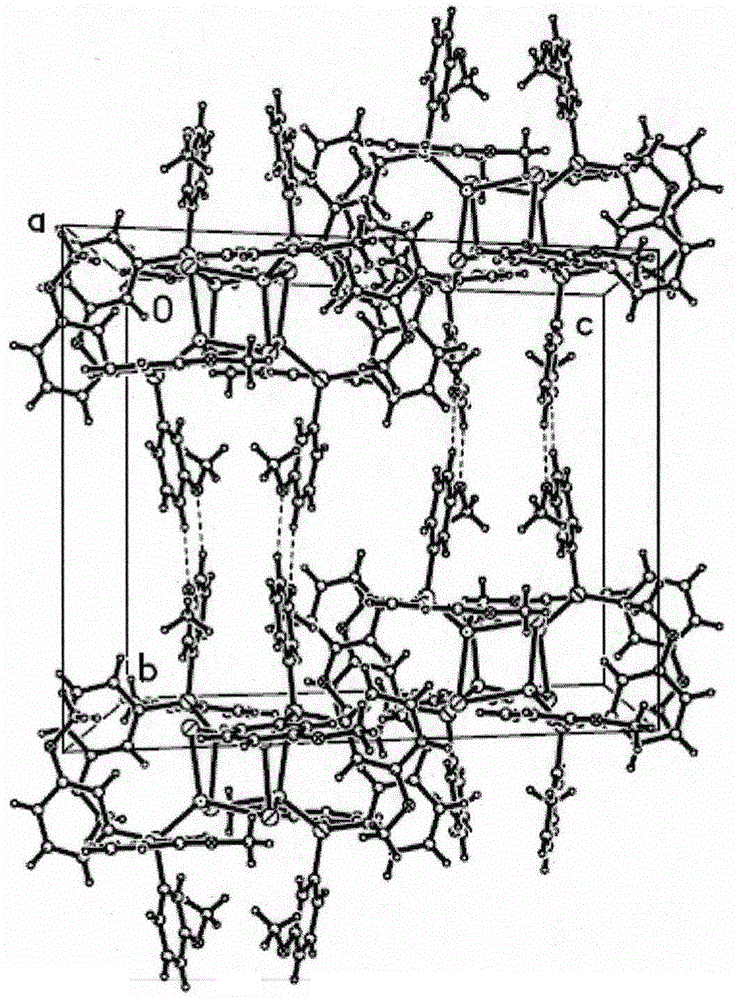

[0032] Synthesis of Cu(I) Complex Cu 4 I 4 (m-anisyl 3 P) 4 single crystal: 0.1 mmol of cuprous iodide was dissolved in 4 mL of acetonitrile to obtain solution A, and 0.1 mmol of m-anisyl was weighed 3 The P ligand was dissolved in 6mL of dichloromethane to obtain solution B. Mix solution A and solution B, and stir to make it fully undergo a coordination reaction. Finally, filter the resulting colorless solution, and cover the filtrate with n-hexane to promote crystallization of the product. After standing for several days, a large number of colorless blocky crystals were precipitated. A colorless crystal with a size of 0.49mm×0.48mm×0.43mm was selected for X-ray single crystal structure test. The molecular structure of the compound is shown in the attached figure 1 , and its unit cell packing structure is shown in the attached figure 2 .

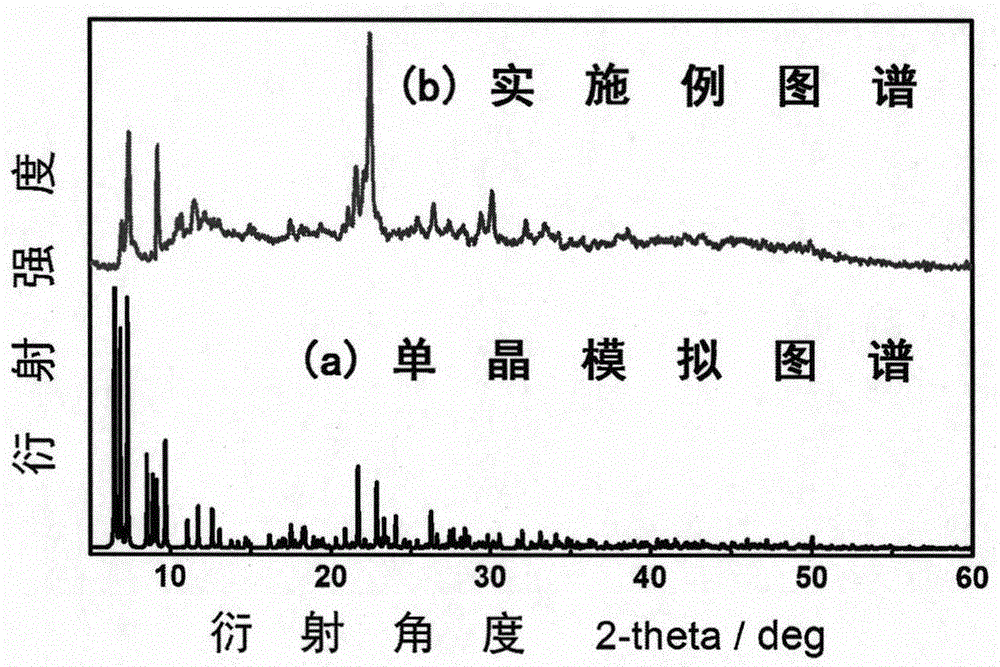

[0033] For the complex Cu 4 I 4 (m-anisyl 3 P) 4 A series of performance tests were carried out on pure phase crystal samples....

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com