Method for preparing temperature-sensitive crosslinked fiber through low-temperature photopolymerization

A technology of low-temperature photopolymerization and photopolymerization of monomers, applied in the field of polymer materials, can solve problems such as taking a long time, and achieve the effect of simple preparation method and high degree of fiber formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

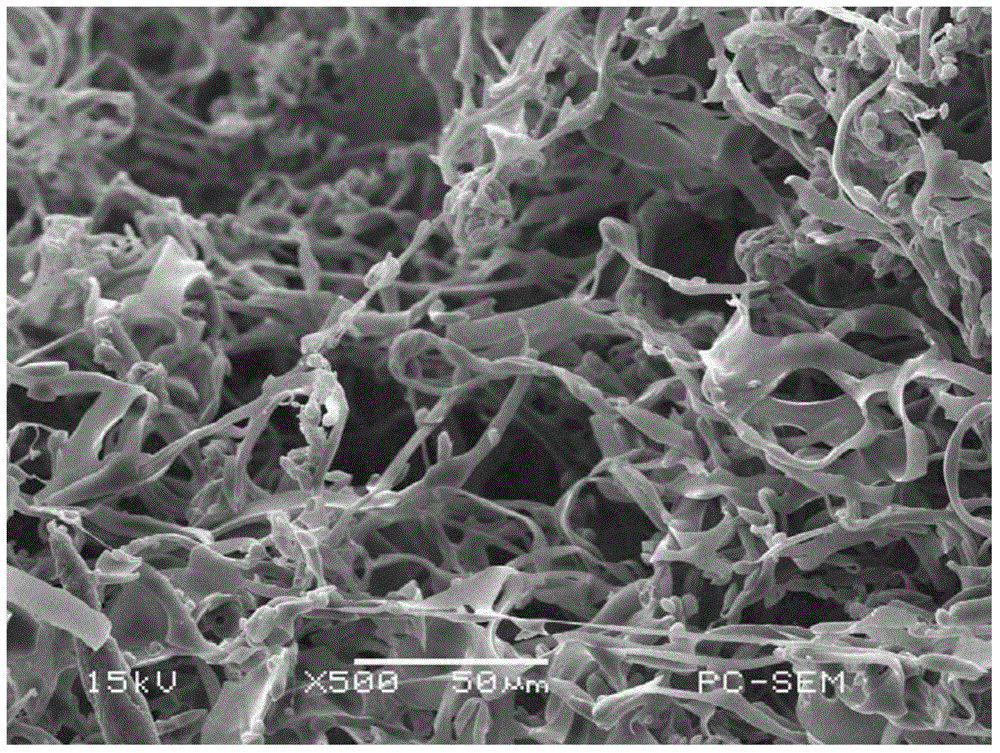

[0026] N-isopropylacrylamide and water-soluble polyethylene glycol (600) diacrylate mixture with photoinitiator 2959 (N-isopropylacrylamide / water-soluble polyethylene glycol (600) diacrylate Mass ratio = 0.1 / 9.9, 2959 and N-isopropylacrylamide and water-soluble polyethylene glycol (600) diacrylate mixture mass ratio = 0.1 / 1) dissolved in solvent water (N-isopropylacrylamide The mass ratio of amide and water-soluble polyethylene glycol (600) diacrylate mixture to water = 1 / 100), frozen at 0°C to freeze and crystallize the water, and cross-linked by ultraviolet light at 0°C , freeze-dried to remove the solvent water, and obtained temperature-sensitive crosslinked fibers, such as figure 1 shown.

Embodiment 2

[0028] The mixture of N-tert-butylacrylamide and water-soluble polyethylene glycol (20000) diacrylate and water-soluble camphorquinone photoinitiator (N-tert-butylacrylamide / water-soluble polyethylene glycol ( 20000) diacrylate mass ratio=9.9 / 0.1, the mass ratio=0.001 / 1) of the mixture of water-soluble camphorquinone photoinitiator and acrylic acid and water-soluble polyethylene glycol (20000) diacrylate) is dissolved in solvent water (The mass ratio of N-tert-butylacrylamide and water-soluble polyethylene glycol (20000) diacrylate mixture to water = 1 / 1000), frozen at -197 ° C to freeze and crystallize water, at -197 The visible light source is irradiated and cross-linked at a low temperature of ℃, and the solvent water is removed by freeze-drying to obtain a temperature-sensitive cross-linked fiber.

Embodiment 3

[0030] Mix N,N diethylacrylamide and water-soluble polyethylene glycol (4000) diacrylate mixture with water-soluble thioxanthone photoinitiator (N,N diethylacrylamide / water-soluble polyethylene glycol Diol (4000) diacrylate mass ratio=5 / 5, water-soluble thioxanthone photoinitiator and N,N diethylacrylamide and water-soluble polyethylene glycol (4000) diacrylate mixture Mass ratio = 0.005 / 1) dissolved in solvent water (mass ratio of N, N diethylacrylamide and water-soluble polyethylene glycol (4000) diacrylate mixture = 5 / 10000), frozen at -50 ° C , making water freeze crystallization, cross-linking with ultraviolet light source light at -20°C, freeze-drying to remove solvent water, and obtaining temperature-sensitive cross-linked fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com