Silicon-chip mechanical arm

A technology of manipulators and silicon wafers, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve the effect of improving the effect, reducing the fragmentation rate, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

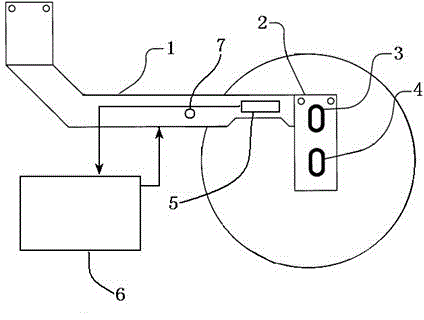

[0024] Such as figure 1 As shown, the present invention provides a kind of manipulator that is used for taking slice in the production of silicon wafer, comprises: manipulator 1, and one end is connected with sliding guide rail; 3, located on the vacuum adsorption gripper 2; the controller 6, the controller 6 can change the position of the mechanical arm 1 and control the work of the vacuum chucks 3 and 4, and also includes a temperature sensor 5, which is arranged on the mechanical arm and transmit the detected temperature signal to the controller 6. After the silicon wafer has been cooled by a high-temperature process for a period of time, the manipulator is used to take the wafer. When taking the sheet, the vacuum chucks 3 and 4 contact the silicon wafer first, and the temperature of the silicon wafer can be transmitted to the temperature sensor 5 through the mechanical arm 1, and the temperature sensor 5 can detect the temperature of the silicon wafer, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com