Preparation method of carbon aerogel

A technology of carbon aerogel and wet gel, applied in the field of aerogel, can solve the problems of low specific surface area of carbon aerogel, difficult control of doping amount and metal particle size, etc. The effect of controllable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Weigh 4.404g resorcinol, 5.6ml formaldehyde, 15ml deionized water and 0.0424g sodium carbonate according to the molar ratio of 1:2:20:0.01; Take 5.816g of nickel nitrate, stir at room temperature for 30 minutes and mix evenly to obtain a dark green resorcinol-formaldehyde-nickel nitrate sol. After adding nickel nitrate, the pH value is 2.8;

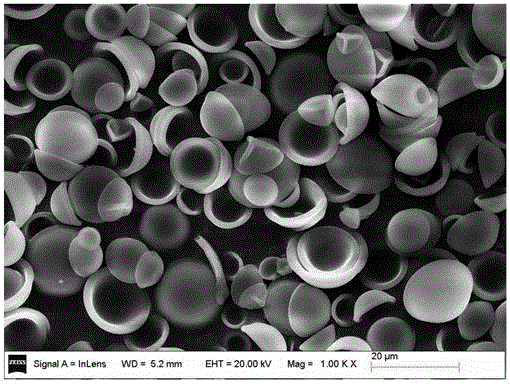

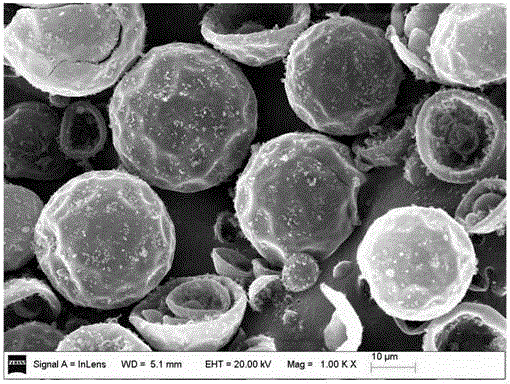

[0027] According to the volume ratio of 1:9, measure 5mL of surfactant Span-80 and 45mL of cyclohexane, stir at 400r / min to form a uniform mixed solution, and then according to the volume of the mixed solution and resorcinol-formaldehyde sol Add 25mL of resorcinol-formaldehyde sol at a ratio of 2:1, continue to stir and react in a water bath at 25°C for 72h, then wash the product with acetone, ethanol and water to clean cyclohexane and Span-80 respectively to obtain intermolecular Hydroquinone-formaldehyde-nickel nitrate organic wet gel microspheres;

[0028] The obtained sample was naturally dried at room temperature to o...

Embodiment 2

[0033] Weigh 8.808g resorcinol, 11.2ml formaldehyde, 30ml deionized water, 0.0848g sodium carbonate according to the molar ratio of 1:2:0.2:20:0.01, and weigh 0.421g of nickel sulfate, stirred at room temperature for 0.1h and mixed evenly to obtain a grassy green resorcinol-formaldehyde-nickel sulfate sol. Add 0.1mol / L to 2mol / L of resorcinol-formaldehyde-nickel nitrate dropwise Sulfuric acid solution, adjust its pH value to 6.5;

[0034]Weigh 6.67ml of surfactant Span-80 and 33.3ml of cyclohexane according to the volume ratio of 1:5, stir at 1200r / min to form a uniform mixed solution, and then mix the mixed solution with resorcinol-formaldehyde sol Add 40mL of resorcinol-formaldehyde sol at a volume ratio of 1:1, continue to stir and react in a water bath at 100°C for 1h, then wash the product with acetone, ethanol and water to clean cyclohexane and Span-80 respectively to obtain Resorcinol-formaldehyde-nickel sulfate organic wet gel microspheres;

[0035] The obtained samp...

Embodiment 3

[0038] Weigh 3.303g of resorcinol, 4.2ml of formaldehyde, 11.25ml of deionized water and 0.0363g of sodium carbonate, weigh 0.599g of copper acetate according to the molar ratio of 1:10 to resorcinol, stir at room temperature for 1h and mix evenly to obtain Blue-green resorcinol-formaldehyde-copper acetate sol, measured after adding copper acetate, its pH value is 4.8;

[0039] According to the volume ratio of 1:80, measure 2ml of surfactant Span-80 and 160mL of cyclohexane, stir at 200r / min to form a uniform mixed solution, and then according to the volume of the mixed solution and resorcinol-formaldehyde sol Add 16.2mL of resorcinol-formaldehyde sol at a ratio of 10:1, continue to stir and react in a water bath at 20°C for 96h, then clean the cyclohexane and Span-80 with acetone, ethanol and water respectively to obtain Resorcinol-formaldehyde-copper acetate organic wet gel microspheres;

[0040] The obtained sample was naturally dried at room temperature to obtain copper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

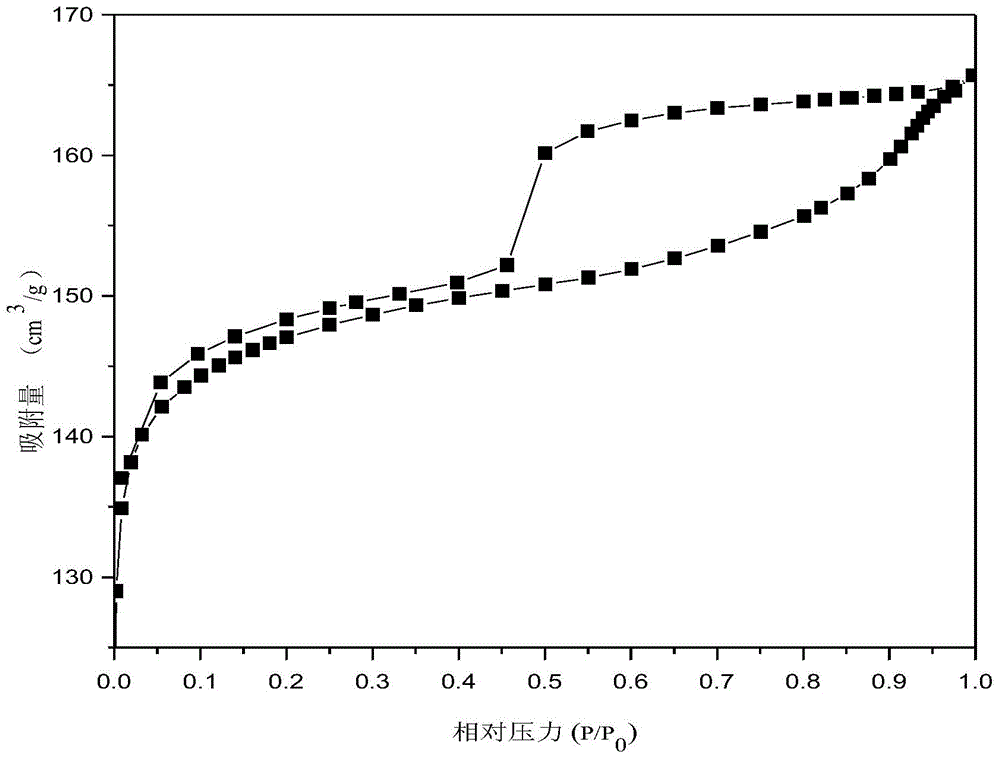

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com