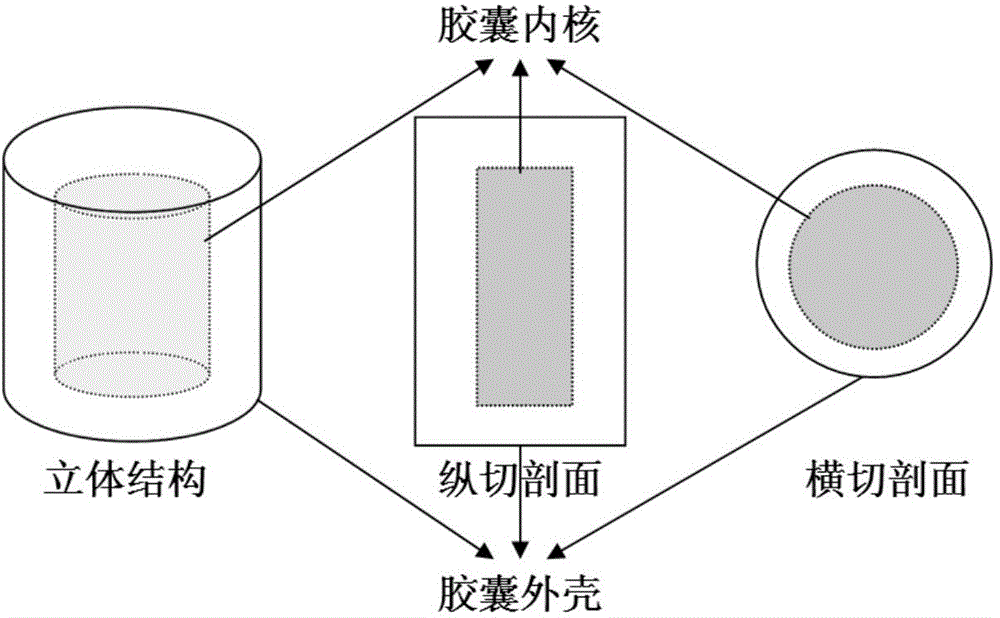

Core-shell structured water purification bacterium capsule and preparation method thereof

A technology of core-shell structure and capsules, which is applied in the field of core-shell structure capsules embedding water purification bacteria agents and slow-release carbon sources and its preparation, which can solve problems such as settlement, reduced application effect, and loss of bacteria agents, and achieve improved stability Effects of sex, duration of action shortening, and duration of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

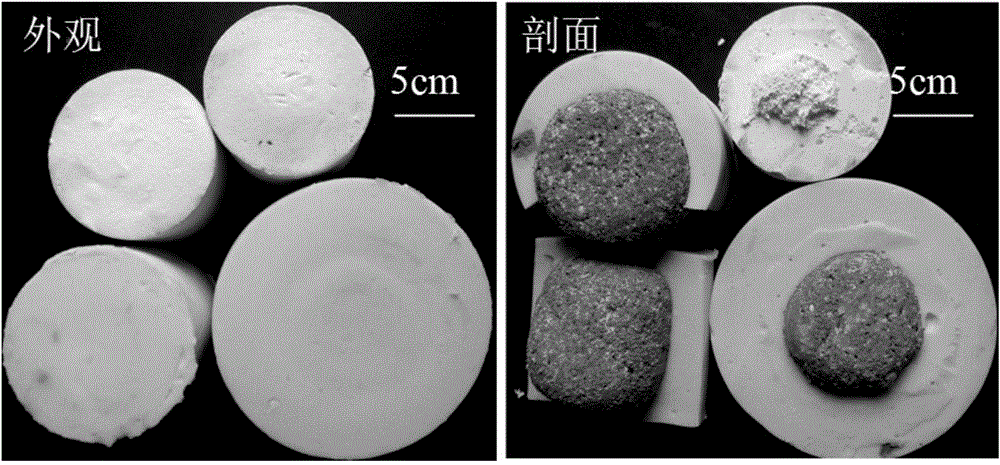

Embodiment 1

[0028] Step 1: Mix 40g sodium citrate, 1g stearic acid, 1g calcium acetate, 1g sodium acetate, 10g calcium chloride, 15.9g bamboo charcoal, 30.0g calcium carbonate, 0.5g xanthan gum, 0.5g sodium alginate and 0.1g The sucrose is mixed well. Then add 10g of water and mix evenly to prepare a dough-like carbon source mixture.

[0029] Step 2: Press the dough-like carbon source mixture into a mold to form a column with a diameter of 1.0 cm and a height of 1.0 cm, and then dry it at 50° C. to obtain the capsule core.

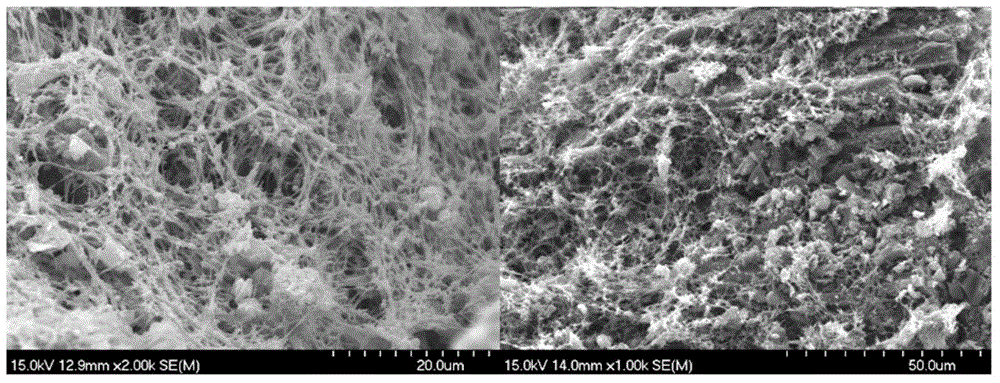

[0030] Step 3: Disperse 0.5g of agar and 0.5g of sodium alginate in 100mL of water, then heat to fully dissolve the agar and sodium alginate, then add 20g of diatomaceous earth and mix evenly, after cooling to 50°C, add 0.2g of bacterial powder and Mix evenly to obtain capsule shell material, and then set aside at 45°C.

[0031] Step 4: Pour the mixed capsule shell material prepared in Step 3 into a cylindrical mold with a diameter of 1.4 cm and a height of 1.4 cm. ...

Embodiment 2

[0036] Step 1: Mix 70g sodium citrate, 1g stearic acid, 1g calcium acetate, 1g sodium acetate, 25.7g calcium chloride, 0.1g bamboo charcoal, 0.1g calcium carbonate, 0.5g xanthan gum, 0.5g sodium alginate and 0.1 g sucrose and mix well. Then add 50g of water and mix evenly to prepare a dough-like carbon source mixture.

[0037] Step 2: Press the dough-like carbon source mixture into a mold to form a column with a diameter of 50.0 cm and a height of about 50.0 cm, and then dry it at 100° C. to obtain the capsule core.

[0038] Step 3: Disperse 4.0g of agar and 5.0g of sodium alginate in 100mL of water, then heat to fully dissolve the agar and sodium alginate, then add 50g of diatomaceous earth and mix evenly, after cooling to 50°C, add 2.0g of bacteria powder and Mix evenly to obtain capsule shell material, and then set aside at 45°C.

[0039] Step 4: Pour the mixed capsule shell material prepared in Step 3 into a cylindrical mold with a diameter of 70.0 m and a height of 70.0...

Embodiment 3

[0044] Step 1: Mix 55g sodium citrate, 5g stearic acid, 1g calcium acetate, 1g sodium acetate, 23.5g calcium chloride, 5.0g bamboo charcoal, 5.0g calcium carbonate, 2.0g xanthan gum, 2.0g sodium alginate and 0.5 g sucrose and mix well. Then add 30g of water and mix evenly to prepare a dough-like carbon source mixture.

[0045] Step 2: Press the dough-like carbon source mixture into a mold to form a column with a diameter of 25.0 cm and a height of about 25.0 cm, and then dry it at 75° C. to obtain the capsule core.

[0046] Step 3: Disperse 2.0g of agar and 2.5g of sodium alginate in 100mL of water, then heat to fully dissolve the agar and sodium alginate, then add 35g of diatomaceous earth and mix evenly, after cooling to 50°C, add 1.0g of bacteria powder and Mix evenly to obtain capsule shell material, and then set aside at 45°C.

[0047] Step 4: Pour the mixed capsule shell material prepared in Step 3 into a cylindrical mold with a diameter of 35.0 m and a height of 35.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com