Aqueous UV coating material and preparation method thereof

A coating and water-based technology, which is applied in the field of water-based UV coatings and its preparation, can solve problems such as spending a lot of time drying, and achieve the effects of reducing curing shrinkage, saving man-hours, and reducing toxicity and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

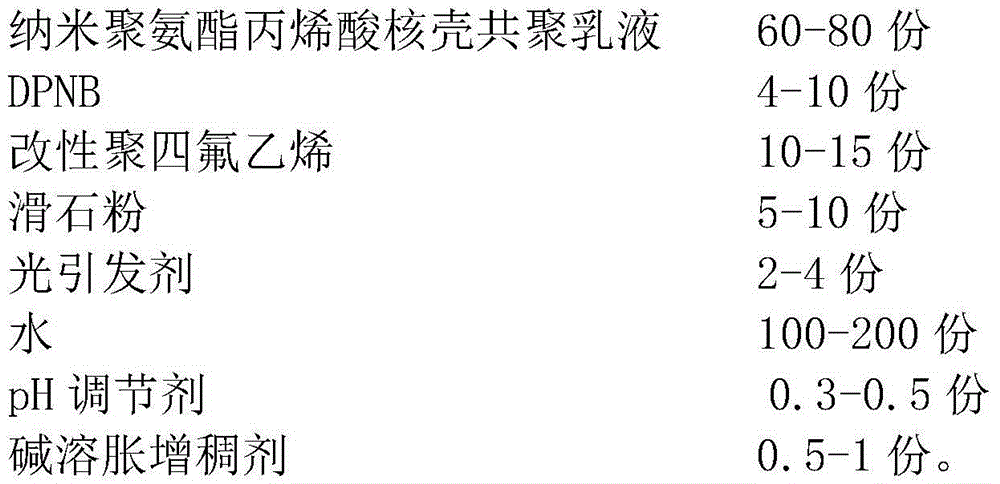

Method used

Image

Examples

Embodiment 1

[0024] A water-based UV coating, comprising the following components in parts by weight: 70 parts of nano polyurethane acrylic core-shell copolymer emulsion, 7 parts of DPNB, 13 parts of modified polytetrafluoroethylene, 7 parts of talcum powder, 3 parts of photoinitiator, 160 parts of water, 0.4 parts of pH regulator, and 0.7 parts of alkali swelling thickener.

[0025] The preparation method of above-mentioned waterborne UV paint, comprises the steps:

[0026] (1) First put 70 parts of nano-urethane acrylic acid core-shell copolymer emulsion into the container and stir at 500-700r / min;

[0027] (2) After mixing 7 parts of DPNB with 7 parts of water, slowly add it into the container;

[0028] (3) After putting in 13 parts of modified polytetrafluoroethylene and 7 parts of talcum powder, disperse at 1000-1200r / min for 20min;

[0029] (4) Slowly add 3 parts of photoinitiator, 153 parts of water, 0.4 part of pH regulator and 0.7 part of alkali swelling thickener into the conta...

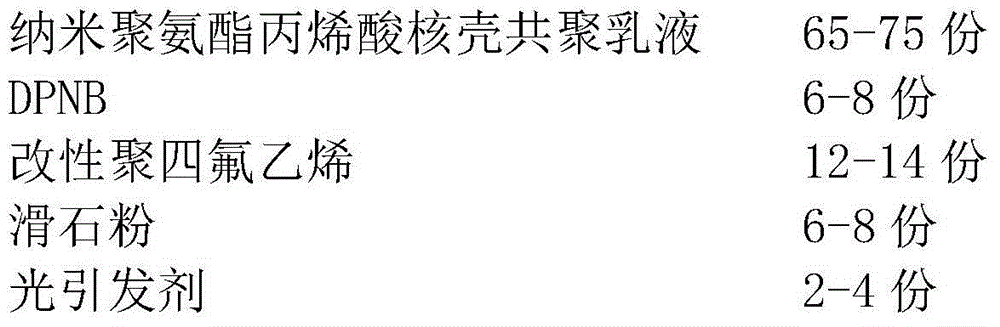

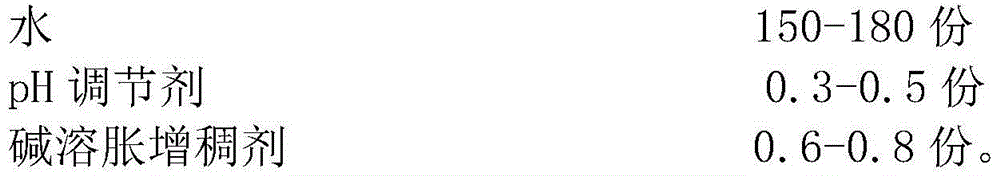

Embodiment 2

[0031] A water-based UV coating, comprising the following components in parts by weight: 65 parts of nano polyurethane acrylic core-shell copolymer emulsion, 6 parts of DPNB, 14 parts of modified polytetrafluoroethylene, 8 parts of talcum powder, 2 parts of photoinitiator, 180 parts of water, 0.3 parts of pH regulator, and 0.6 parts of alkali swelling thickener.

[0032] The preparation method of above-mentioned waterborne UV paint, comprises the steps:

[0033] (1) First put 65 parts of nano polyurethane acrylic acid core-shell copolymer emulsion into the container and stir at 500-700r / min;

[0034] (2) After mixing 6 parts of DPNB with 6 parts of water, slowly add it into the container;

[0035] (3) After putting in 14 parts of modified polytetrafluoroethylene and 8 parts of talcum powder, disperse at 1000-1200r / min for 25min;

[0036] (4) Slowly add 2 parts of photoinitiator, 172 parts of water, 0.3 part of pH regulator and 0.6 part of alkali swelling thickener into the c...

Embodiment 3

[0038] A water-based UV coating, comprising the following components in parts by weight: 75 parts of nano polyurethane acrylic core-shell copolymer emulsion, 8 parts of DPNB, 12 parts of modified polytetrafluoroethylene, 6 parts of talcum powder, 4 parts of photoinitiator, 150 parts of water, 0.5 parts of pH regulator, and 0.8 parts of alkali swelling thickener.

[0039] The preparation method of above-mentioned waterborne UV paint, comprises the steps:

[0040] (1) First put 75 parts of nano-urethane acrylic acid core-shell copolymer emulsion into the container and stir at 500-700r / min;

[0041] (2) After mixing 8 parts of DPNB with 8 parts of water, slowly add it into the container;

[0042] (3) After putting in 12 parts of polytetrafluoroethylene and 6 parts of talcum powder, disperse at 1000-1200r / min for 25 minutes;

[0043] (4) Slowly add 4 parts of photoinitiator, 142 parts of water, 0.5 part of pH regulator and 0.8 part of alkali swelling thickener into the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com