Process for preparing high-octane-rating high-cleaning gasoline based on naphtha and methanol as raw materials

A high-octane, naphtha technology, applied in the petroleum industry, naphtha treatment, etc., can solve the problems of large liquefied gas production, gasoline standards, poor economic benefits, etc., to achieve sufficient raw materials and economic benefits Significant, scientific and novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

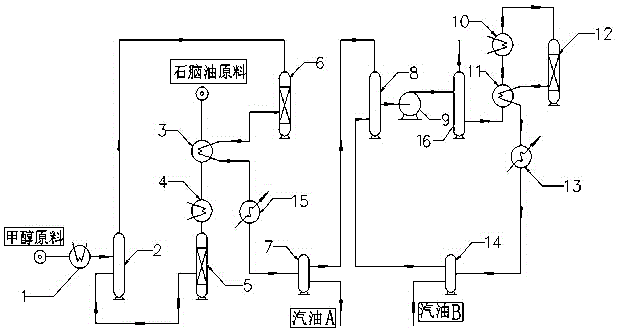

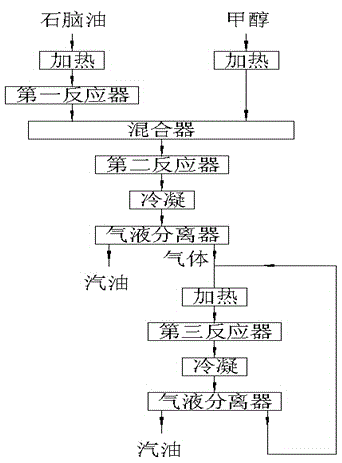

Method used

Image

Examples

Embodiment 1

[0049] Prepare the first reactor catalyst, the catalyst uses SiO 2 / Al 2 o 3 The 38 NKF-5 molecular sieve is molded and roasted, and treated with water vapor with α value = 200. Put the prepared catalyst into the first reactor, the reaction temperature is 321°C, the specific gravity of the raw material is 0.648, the RON (octane number) is 70, the space velocity is 0.25, the specific gravity of the product oil is 0.68g / ml, the RON is 84.5, and gas is produced—— Dry gas (carbon 1 and carbon 2) 2%, C 3 -C 4 Gas contains 19.25%.

Embodiment 2

[0051] Put the prepared catalyst into the second reactor. The main component of the catalyst is SiO2 / Al2O3=480, the grain size is ≈400nm high silicon ZSM-5 and SAPO-11 molecular sieve, the mixing ratio is 85:15, and the reaction temperature is 370℃± 3. Airspeed 0.5h -1 , pure methanol reacted for 192 hours, the conversion rate of methanol was greater than 99.6%, the hydrocarbon number of methanol converted to gasoline was 50.81%, the octane number of gasoline was 94, and the rest was gas, accounting for 49.19%, of which methane was 0.56%, ethylene ethane 4.57%, the rest is liquefied petroleum gas, 44.06% of liquefied petroleum gas above C3, of which olefins account for 21%, accounting for 47.74% of liquefied petroleum gas, the gasoline produced by methanol has an octane number of 94.

Embodiment 3

[0053] Put the prepared catalyst in the second reactor with example two, high silicon ZSM-5 molecular sieve content 68%, SAPO-11 molecular sieve 12%, pseudoboth aluminum 20% as binder, the specific physical and chemical properties of catalyst amount The properties are as follows:

[0054] The ratio of methanol to naphtha in the reactant is 10:5, the space velocity is 0.74, and the reaction temperature is 370°C-380°C. After the reaction, the reaction product is cooled by a cooler, and the reaction product oil and gas are separated by a gas-liquid separator. The calculation is a simple calculation: the hydrocarbon number of methanol is 51.6% for gasoline, 48.4% for gas, part of the olefins in the gas undergoes alkylation reaction, 0.705% of methane in the remaining gas, 3.72% of ethane plus ethylene, and 43.98% is C3 Of the above liquefied petroleum gas, olefins accounted for 25.92%, accounting for 58.94% of liquefied petroleum gas. The resulting oil measured 93 octane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com