Preparation technology for Ni submicron arrays

A preparation process, sub-micron technology, applied in the direction of metal material coating process, vacuum evaporation plating, coating, etc., can solve problems such as unsuitable for large-scale application, environmental pollution of raw materials, complex process, etc., to improve electrochemical performance , good repeatability, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

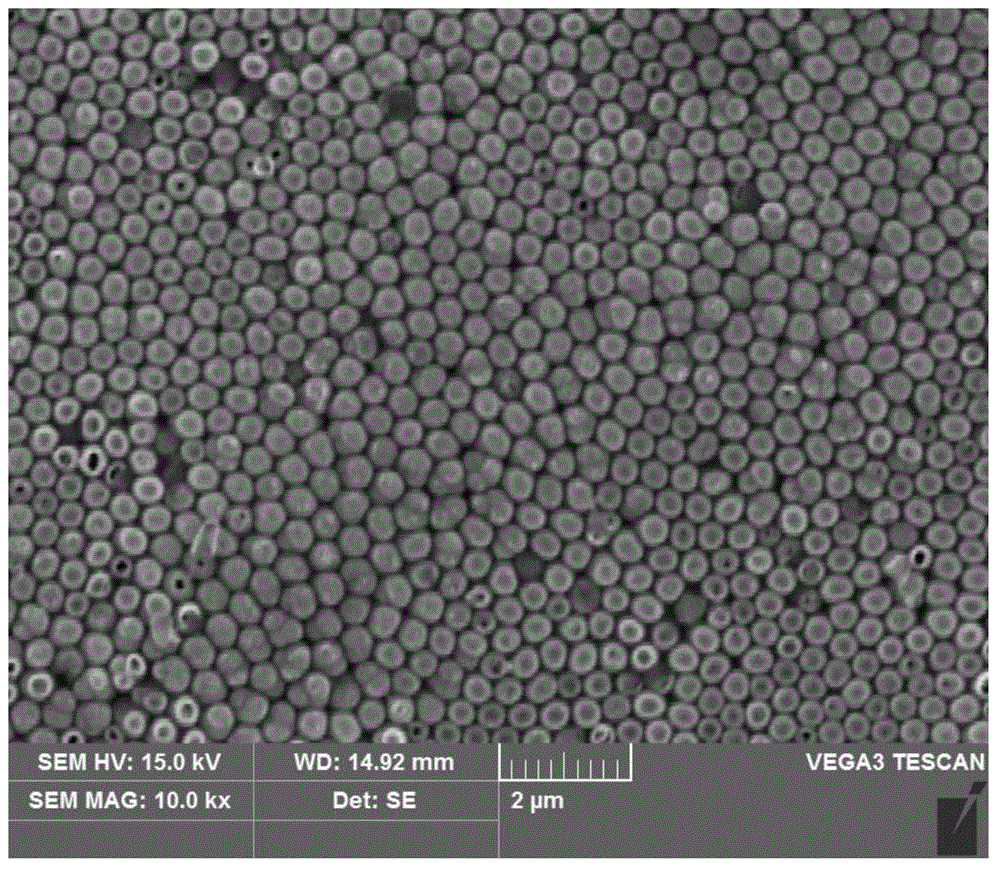

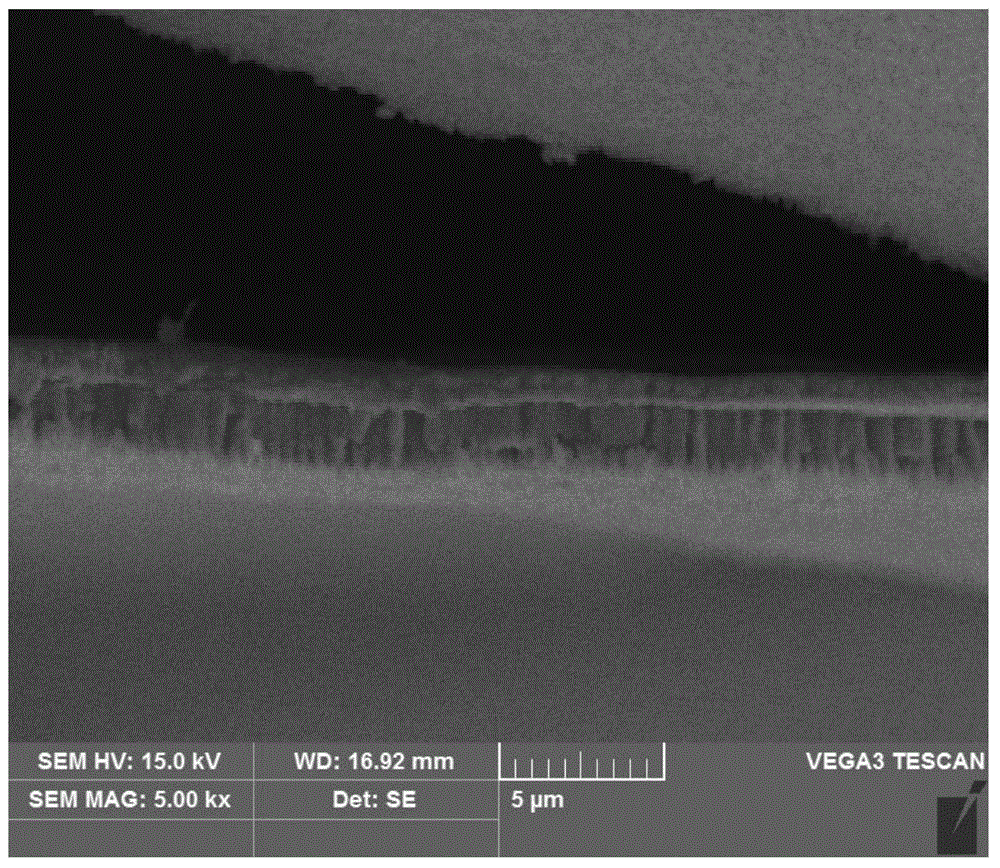

[0026] like figure 1 and figure 2 Shown:

[0027] This embodiment adopts SD-550 ultra-high vacuum multifunctional magnetron sputtering equipment (Chengdu Shengda Xingye Chemical Engineering Co., Ltd.);

[0028] The substrate used is a commercial AAO template (Lesson Nano company);

[0029] The purity of the sputtered metal Ni used is 99.999%;

[0030] The purity of working gas Ar is 99.999%;

[0031] The whole deposition process is carried out at room temperature;

[0032] Under the above conditions, the preparation steps of Ni submicron array are as follows:

[0033] (1) Pretreatment of substrate and Ni target before deposition

[0034] a. Cleaning the substrate: first put the substrate into 99.5% acetone and clean it with an ultrasonic cleaner for 15 minutes, then put it in 99.7% absolute ethanol and clean it with an ultrasonic cleaner for 10 minutes, after drying, put it into an ultra-high Vacuum multifunctional magnetron sputtering equipment vacuum chamber, when th...

Embodiment 2

[0045] This embodiment adopts SD-550 ultra-high vacuum multifunctional magnetron sputtering equipment (Chengdu Shengda Xingye Chemical Engineering Co., Ltd.);

[0046] The substrate used is a commercial AAO template (Lesson Nano company);

[0047] The purity of the sputtering metal Ni used is 99.999%; the purity of the working gas Ar is 99.999%;

[0048] The whole deposition process is carried out at room temperature;

[0049] Under the above conditions, the preparation steps of Ni submicron array are as follows:

[0050] (1) Pretreatment of substrate and Ni target before deposition

[0051] a. Clean the substrate: first put the substrate in 99.5% acetone and clean it with an ultrasonic cleaner for 10 minutes, then put it in 99.7% absolute ethanol and clean it with an ultrasonic cleaner for 15 minutes, and put it in an ultrahigh Vacuum multifunctional magnetron sputtering equipment vacuum chamber, when the vacuum degree reaches 4.0×10 -4 Pa, and then perform backsputter cl...

Embodiment 3

[0061] This embodiment adopts SD-550 ultra-high vacuum multifunctional magnetron sputtering equipment (Chengdu Shengda Xingye Chemical Engineering Co., Ltd.);

[0062] The substrate used is a commercial AAO template (Lesson Nano company);

[0063] The purity of the sputtering metal Ni used is 99.999%; the purity of the working gas Ar is 99.999%;

[0064] The whole deposition process is carried out at room temperature;

[0065] Under the above conditions, the preparation steps of Ni submicron array are as follows:

[0066] (1) Pretreatment of substrate and Ni target before deposition

[0067] a. Cleaning the substrate: first put the substrate into 99.5% acetone and clean it with an ultrasonic cleaner for 12 minutes, then put it into 99.7% absolute ethanol and clean it with an ultrasonic cleaner for 12 minutes, after drying, place it in an ultra-high Vacuum multifunctional magnetron sputtering equipment vacuum chamber, when the vacuum degree reaches 4.0×10 -4 Pa, and then pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com