A liquid leakage detection sensor using ion sputtering coating circuit and its manufacturing process

A detection sensor, ion sputtering technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, instrument, etc., can solve the problem of difficulty in correctly detecting liquid leakage or not accurately locating the leak location. , The adhesion between the base film layer and the protective film layer 130 is reduced, and the liquid leakage distance cannot be accurately indicated, so as to reduce the defect rate, reduce the possibility of peeling, and minimize false alarms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Such as Figure 3-14 As shown, the manufacturing process of the liquid leakage detection sensor using the ion sputtering coating circuit described in the embodiment of the present invention consists of the following steps:

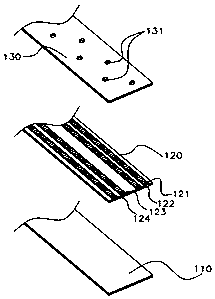

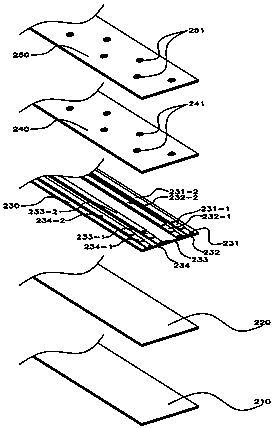

[0045] (1) Use PI, PET, PO, PTFE heat-resistant and corrosion-resistant materials as the base film 220, form an insulating substance coating 230 on its upper surface by ion sputtering coating process to improve the insulation resistance, and then use the above-mentioned insulating coating 230 Two pairs of conductive lines, namely, conductive lines 231, 232, 233, and 234, are fabricated by ion sputtering coating method, so that they are arranged in parallel lines at a certain distance;

[0046] (2) The above-mentioned base film 220 is followed by conductive lines 231, 232, 233, 234, and the upper surface of the insulating coating 230 is provided with an adhesive layer 240 and a protective film layer 250 that are attached to each other. The protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com