Device for common voltage high voltage radio cooperation radio frequency glow jet discharge and discharge method

A jet discharge and radio frequency technology, applied in the direction of plasma, can solve the problems of low plasma temperature and low plasma density, and achieve the effect of less discharge pollution, abundant sources and increased concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

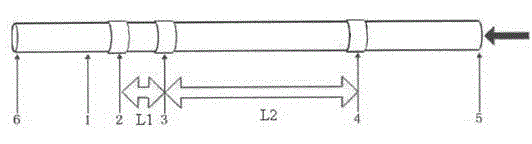

[0020] Such as figure 1 As shown, a discharge tube body 1 is included. One end of the discharge tube body 1 is an air inlet 5 and the other end is an air outlet 6. The discharge tube body 1 is sequentially provided with three groups of electrodes, a first group of electrodes 2, a common electrode 3, and a second group of electrodes 4. The first group of electrodes 2 is connected to a high voltage source, the common electrode 3 is grounded, and the second group of electrodes 4 is connected to a radio frequency source. The radio frequency source adopts alternating current with a frequency of 2MHz-100MHz and a power of 5W-1000W; the high-voltage source is a direct-current pulse or high-voltage alternating current source with a frequency of 1Hz-1KHz and a power of 30W-1000W. The discharge tube body 1 adopts a quartz tube with a circular cross-section, with an inner diameter of 6mm, a wall thickness of 1mm, and a length of 450mm; the dimensions of the three groups of electrodes are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com