Method for preserving crop straw through sulfur dioxide and application

A technology of crop straw and sulfur dioxide, which is applied in the directions of botanical equipment and methods, applications, agricultural machinery and implements, etc., can solve the problems of reducing market competitiveness, complicated pressing operations, and increasing production costs, so as to avoid low mass transfer efficiency, The effect of using a wide range and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 Preservation of whole bar of sweet sorghum

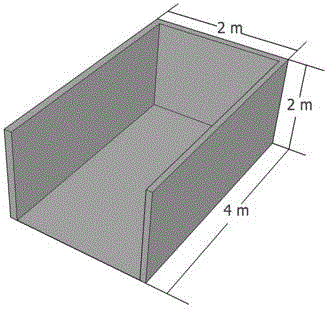

[0033] After harvesting the sweet sorghum, remove the sorghum ears and leaves, cut the root, middle and top of the sorghum stalks respectively to make them into 1-3m long stalks, collect and bundle the cut stalks. The above can be harvested manually, or can be harvested by mechanized combine harvester, leaf stripping and other operations; put the whole bar of sweet sorghum into the silage silo with a height of 2m, a length of 4m and a width of 2m ( figure 1), during which the sweet sorghum stalks are placed upside down on the ground along the longitudinal direction of the silo and piled up. Do not compact during the whole stacking process, and just stack them naturally. During the filling process, 2 g aluminum phosphide tablets (56 wt %) were added per ton of sweet sorghum. The filling rate of the silage silo is 70%. After filling, use agricultural plastic film to cover the materials in the silo, wrap the edge ...

Embodiment 2

[0035] Embodiment 2 Preservation of short stalks of sweet sorghum

[0036] After the sweet sorghum is harvested, the ears and leaves of the sorghum are removed, and the stalks are cut into 3-30 cm long and short rods by manual cutting. The above can be harvested by a mechanized combine harvester and directly cut into short stalks. Put the short stalk sweet sorghum into the high 2m long, 4m wide, 2m silage silo ( figure 1 ), during which the sweet sorghum stalks are piled up vertically, and the whole stacking process should not be compacted, just stack them naturally. During the filling process, 10 g of aluminum phosphide tablets (56 wt%) were added per ton of sweet sorghum. The filling rate of the silage silo is 95%. After filling, use agricultural plastic film to cover the materials in the silo, wrap the edge of the sweet sorghum stack with the plastic film, make the plastic film closely contact with the cement wall and the ground, and fix the plastic film on the surface o...

Embodiment 3

[0038] The preservation of embodiment 3 sweet sorghum pulverized material

[0039] After the sweet sorghum is harvested, the whole plant of sweet sorghum is crushed into particles with a particle size of 2-20 mm by a pulverizer, or directly crushed and harvested in the field by a silage harvester, and the particle size is 2-30 mm.

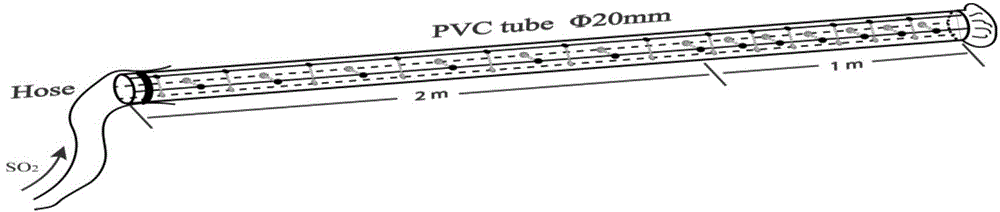

[0040] The crushed sweet sorghum is put into the silage silo ( figure 1 ), avoid compaction during the whole stacking process, and just stack it naturally. During the filling process, 4 g of aluminum phosphide tablets (56 wt %) were added per ton of sweet sorghum. The filling rate of the silage silo is 70%. After filling, use agricultural plastic film to cover the materials in the silo, wrap the edge of the sweet sorghum stack with the plastic film, make the plastic film closely contact with the cement wall and the ground, and fix the plastic film on the surface of the sweet sorghum stack with sand bags and the like. Insert a 20mm-diameter PVC p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com