Microbial active filler containing paenibacillus sp., and application thereof

A technology of microbial activity and bacillus, applied in the field of environmental governance, can solve the problems of slow startup, easy shedding of load, poor acid and high temperature resistance, etc., and achieve the effect of short adaptation period, not easy to rot and deform, and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

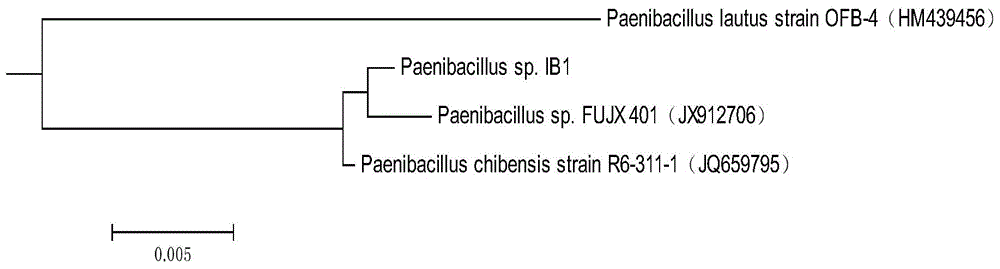

[0044] Embodiment 1: strain identification

[0045] Using the automatic magnetic bead nucleic acid extractor Smart LabAssist-16 and the corresponding environmental sample DNA extraction and purification kit (Taiwan Dot Nano Technology Co., Ltd.) to extract and purify the DNA of the bacterial strains screened separately, the bacterial general primer F16S-27 was selected and R16S-1492 for PCR amplification, the primer sequences are:

[0046] F16S-27 (5`-AGAGTTTGATCCTGGCTCAG-3`)

[0047] R16S-1492 (5`-CGGTTACCTTGTTACGACTTC-3`)

[0048] The PCR reaction conditions were set as follows: 94°C pre-denaturation for 5 min; followed by 94°C denaturation for 30 s, 56°C annealing for 30 s, 72°C extension for 90 s, and 25 cycles; then 72°C extension for 10 min; and finally 4°C for 10 min. The PCR product was then ligated to the PMD-19T vector (Dalian Bao Biological Co., Ltd.), and then transformed into E. coli DH5α competent cells (Dalian Bao Biological Co., Ltd.). Spread 50 μl of transf...

Embodiment 2

[0049] Example 2: A microbial filler for removing sulfur dioxide-containing gas and its preparation

[0050] A microbial active filler for removing sulfur dioxide-containing gas, the filler is attached with Paenibacillus sp. IB1 bacterial suspension, the Paenibacillus sp. IB1 has a preservation number of CGMCC No.10775, and the filler is polyurethane foam block;

[0051] The packing density is 15kg / m 3 , the porosity is 90%, the particle size is 20mm;

[0052] The Paenibacillus IB1 is attached to the filler in the form of bacterial suspension;

[0053] The mass ratio of the Paenibacillus IB1 bacterial suspension to the filler is 60:10;

[0054] The concentration of Paenibacillus IB1 cells in the microbial activity filler is 1.1×10 6 CFU / g;

[0055] The preparation steps of the microbial active filler are as follows:

[0056] (1) Incline culture: prepare Paenibacillus sp. (Paenibacillus sp.) IB1 slant bacteria;

[0057] The Paenibacillus IB1 slant medium consists of: glu...

Embodiment 3

[0066] Example 3: A microbial filler for removing sulfur dioxide-containing gas and its preparation

[0067] A microbial active filler for removing sulfur dioxide-containing gas, the filler is loaded with Paenibacillus sp. IB1 bacterial suspension, the Paenibacillus sp. IB1 has a preservation number of CGMCC No.10775, and the filler is volcanic rock ;

[0068] The packing density is 25kg / m 3 , the porosity is 55%, and the particle size is 10mm;

[0069] The Paenibacillus IB1 is attached to the filler in the form of bacterial suspension;

[0070] The mass ratio of the Paenibacillus IB1 bacterial suspension to the filler is 36:10;

[0071] The concentration of Paenibacillus IB1 thallus in the microbial active filler is 3.5×10 6 CFU / g;

[0072] The preparation steps of the microbial active filler are as follows:

[0073] (1) Incline culture: prepare Paenibacillus sp. (Paenibacillus sp.) IB1 slant bacteria;

[0074] The Paenibacillus IB1 slant medium consists of: glucose 0.5g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com