Fish bone charcoal adsorbent and preparation method and application thereof

An adsorbent and fishbone charcoal technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve expensive problems, achieve easy regeneration, simple preparation methods, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

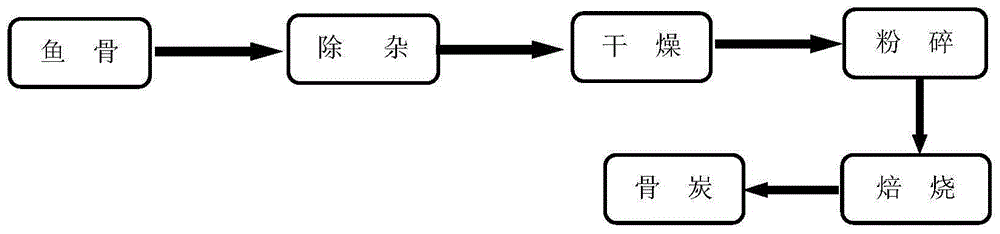

[0024] A preparation method of a novel herringbone charcoal adsorbent, comprising the following steps:

[0025] 1): Remove impurities, stir and scald the obtained freshwater fish bones in hot water at 80-100°C to remove impurities;

[0026] 2): drying, drying the fish bones after removing impurities in an oven at 50-100°C;

[0027] 3): Grinding, the dried fish bones are crushed with a universal grinder, the crushing time is 10-20s, and the interval is 1-5 minutes, and this is repeated 10-20 times to make fish bone powder with a particle size of 100 mesh, which is used as the raw material of the adsorbent;

[0028] 4): High-temperature roasting, the prepared 3g fish bone meal is roasted and carbonized in a closed muffle furnace at 500°C for 1 hour, the heating rate is 5°C / min, and then naturally cooled to room temperature and taken out to obtain fish bone charcoal adsorption agent.

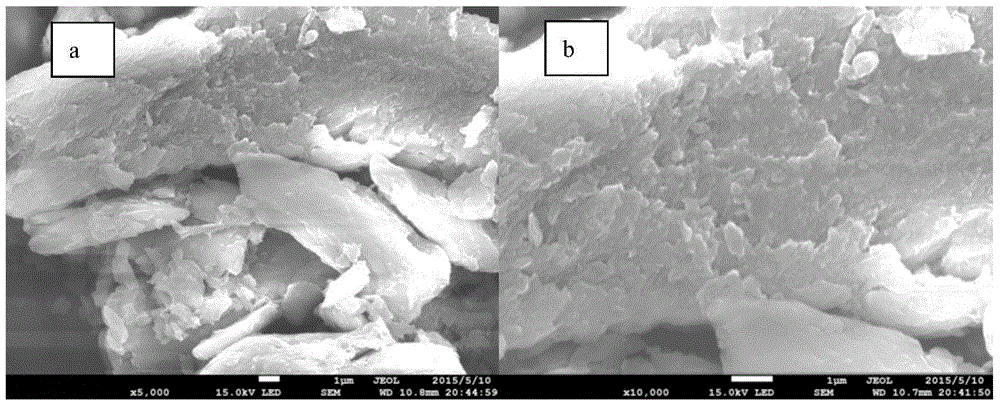

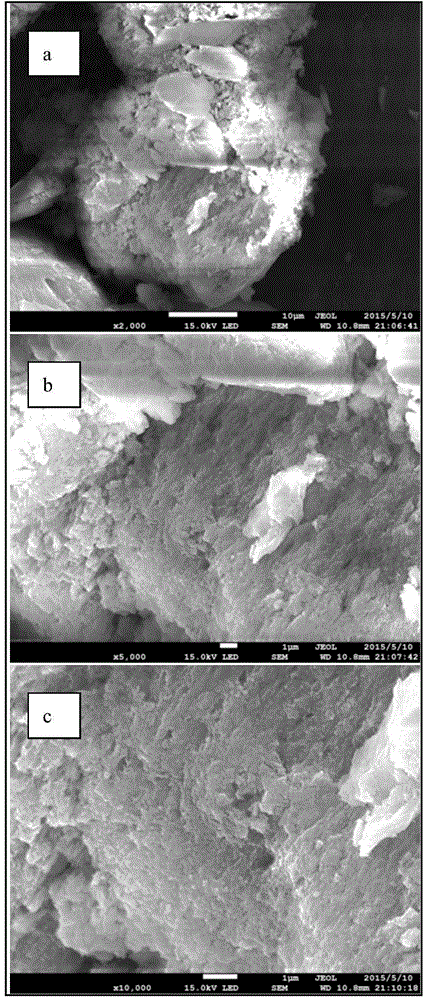

[0029] When the fishbone meal of the present invention has not been treated at high temperatu...

Embodiment 2

[0041] A preparation method of a novel herringbone charcoal adsorbent, comprising the following steps:

[0042] 1): Remove impurities, stir and scald the obtained freshwater fish bone raw materials in hot water at 80-100°C to remove impurities;

[0043] 2): drying, drying the fish bones after removing impurities in an oven at 50-100°C;

[0044] 3): Grinding, the dried fish bones are crushed with a universal grinder, the crushing time is 10-20s, and the interval is 1-5 minutes, and this is repeated 10-20 times to make fish bone powder with a particle size of 100 mesh, which is used as the raw material of the adsorbent;

[0045] 4): High-temperature roasting, the prepared 3g fish bone powder is roasted and carbonized in a closed muffle furnace at 580°C for 1 hour, the heating rate is 4°C / min, and then naturally cooled to room temperature and taken out to obtain fish bone charcoal adsorption agent.

[0046] Table 2 is the removal effect of Example 2 on As(Ⅴ).

[0047] ...

Embodiment 3

[0050] A preparation method of a novel herringbone charcoal adsorbent, comprising the following steps:

[0051] 1): Remove impurities, stir and scald the obtained freshwater fish bone raw materials in hot water at 80-100°C to remove impurities;

[0052] 2): drying, drying the fish bones after removing impurities in an oven at 50-100°C;

[0053] 3): Grinding, the dried fish bones are crushed with a universal grinder, the crushing time is 10-20s, and the interval is 1-5 minutes, and this is repeated 10-20 times to make fish bone powder with a particle size of 100 mesh, which is used as the raw material of the adsorbent;

[0054] 4): High-temperature roasting, the prepared 3g of fish bone powder is roasted and carbonized in a closed muffle furnace at 420°C for 2 hours, the heating rate is 5°C / min, and then naturally cooled to room temperature and taken out to obtain fish bone charcoal adsorption agent.

[0055] Table 3 shows the removal effect of Example 3 on Pb(II).

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com