Non-noble metal denitration catalyst as well as preparation method and application thereof

A denitrification catalyst and non-precious metal technology, applied in the field of catalysts, can solve the problems of vanadium-based catalysts, such as toxicity and environmental hazards, catalyst catalytic activity and selectivity reduction, etc., achieve good catalytic activity and stability, simple and convenient synthesis process, and low toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

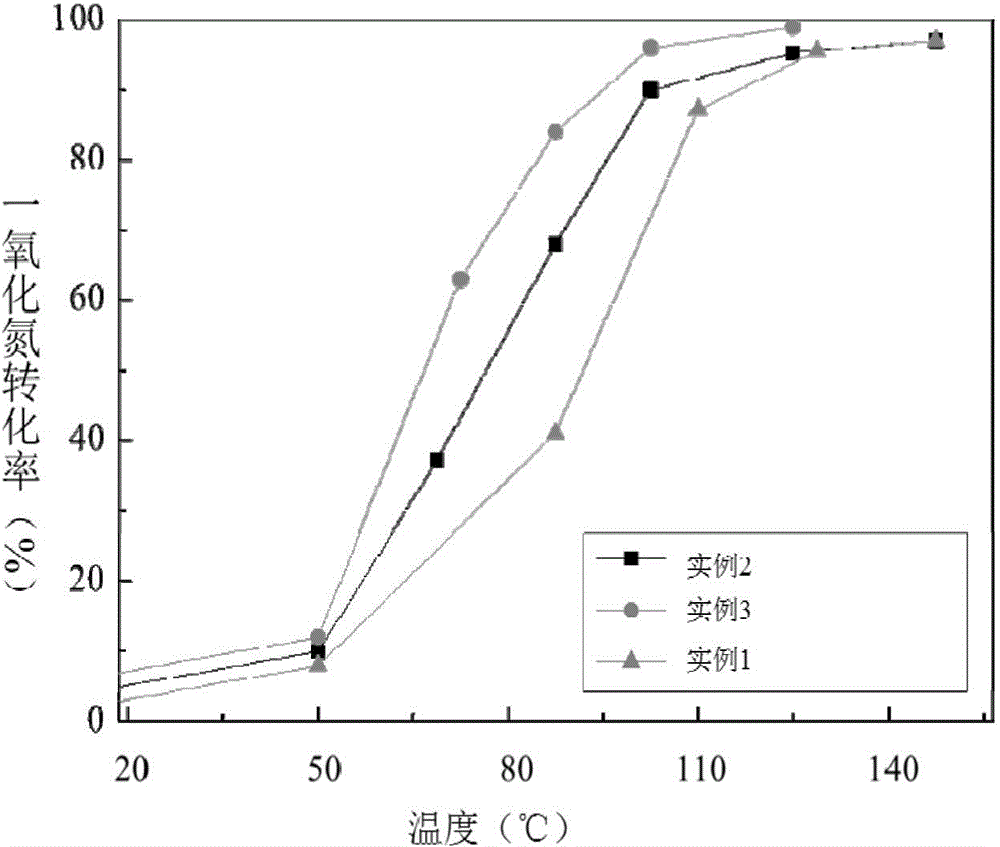

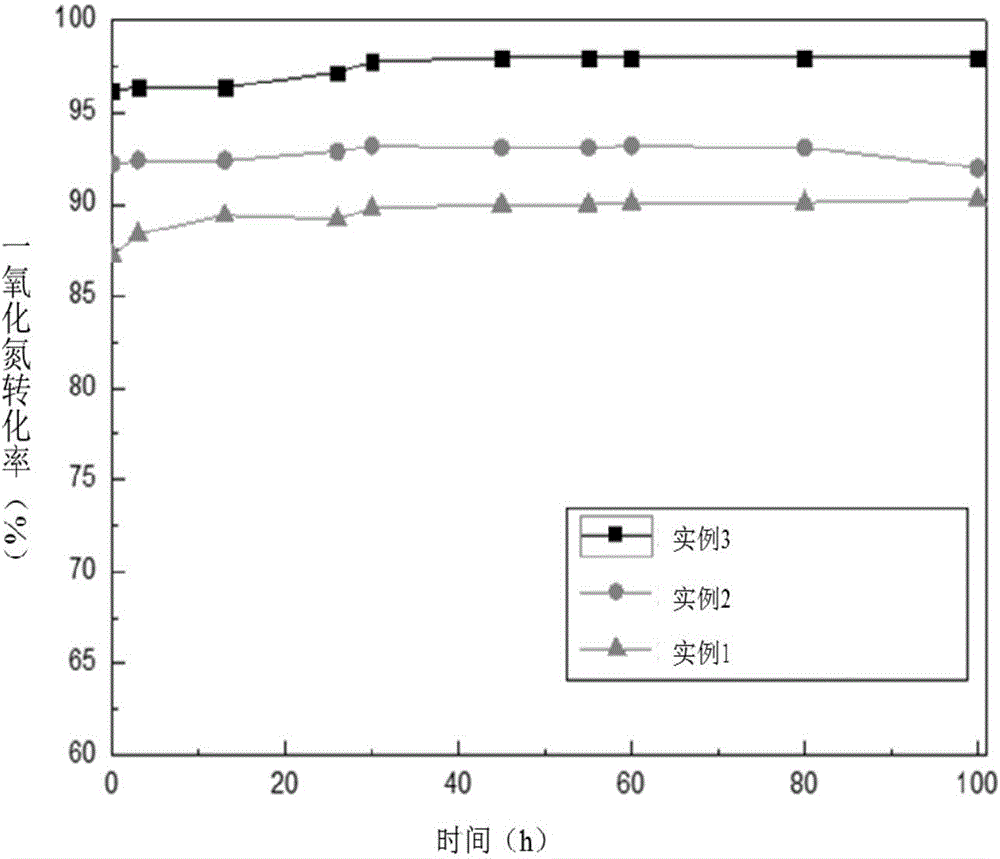

Embodiment 1

[0040] A preparation method of a non-precious metal denitration catalyst, specifically comprising the following steps:

[0041] (1) Add 6.4g of copper nitrate and 11g of manganese nitrate into 100g of deionized water to make a solution, then add 75g of Al 2 o 3 The carrier (i.e. alumina) was stirred at a constant speed at room temperature for 1 hour at a speed of 100 r / min, and then ultrasonically dispersed for 30 minutes (ultrasonic frequency was 40KHz) to obtain a dispersion;

[0042] (2) Use a rotary evaporator to evaporate the dispersion in step (1) at 80°C to dry up the solvent, then dry it at 100°C for 6 hours, and then heat it up in a muffle furnace at a rate of 2°C / min to Calcined at 450°C for 4 hours to obtain a composite carrier;

[0043](3) The composite carrier of step (2) is added into 100g deionized water, and ball milled for 5h (the ball milling speed is 400r / min) to obtain a ball mill; add 10g ethanol to the ball mill, and the ball mill is stirred for 5min (t...

Embodiment 2

[0045] A preparation method of a non-precious metal denitration catalyst, specifically comprising the following steps:

[0046] (1) Add 6.4g of copper nitrate, 11g of manganese nitrate, and 16.8g of cerium nitrate (analytical pure) into 100g of deionized water to make a solution, then add 90g of Al 2 o 3 The carrier (i.e. alumina) was stirred at room temperature for 1.5 hours at a constant speed at a speed of 200r / min, and then ultrasonically dispersed for 35min (ultrasonic frequency was 40KHz) to obtain a dispersion;

[0047] (2) Use a rotary evaporator to evaporate the dispersion in step (1) at 80°C to dry up the solvent, then dry it at 110°C for 5 hours, and then heat it up in a muffle furnace at a rate of 2°C / min to Calcined at 400°C for 5 hours to obtain a composite carrier;

[0048] (3) Add 120g deionized water to the composite carrier of step (2), and ball mill for 6h (the speed of ball milling is 400r / min) to obtain a ball mill; add 14g ethanol to the ball ink slurry...

Embodiment 3

[0050] A preparation method of a non-precious metal denitration catalyst, specifically comprising the following steps:

[0051] (1) Add 6.4g copper nitrate, 11g manganese nitrate, 16.8g cerium nitrate, 11.4g zirconium nitrate to 100g deionized water to form a solution, then add 100gAl 2 o 3 The carrier (i.e. aluminum oxide) was stirred at a constant speed at room temperature for 2 hours at a speed of 150r / min, and then ultrasonically dispersed for 40min (ultrasonic frequency was 40KHz) to obtain a dispersion;

[0052] (2) Use a rotary evaporator to evaporate the dispersion in step (1) at 80°C to dry up the solvent, dry at 90°C for 7 hours, and heat up to 500°C for 3 hours in an air atmosphere in a muffle furnace at a rate of 2°C / min. , to prepare a composite carrier;

[0053] (3) The composite carrier of step (2) is added into 150g deionized water, and ball milled for 5.5h (the ball milling speed is 400r / min) to obtain a ball mill; add 20g ethanol to the ball ink slurry, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com