Upflow reaction and separation integrated powder resin purifier and purification method thereof

A powder resin and purifier technology, applied in the direction of adsorption water/sewage treatment, etc., can solve the problems of high power consumption of resin return, low separation efficiency, large floor space, etc., to reduce operating costs, reduce equipment floor space, The effect of avoiding operational failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

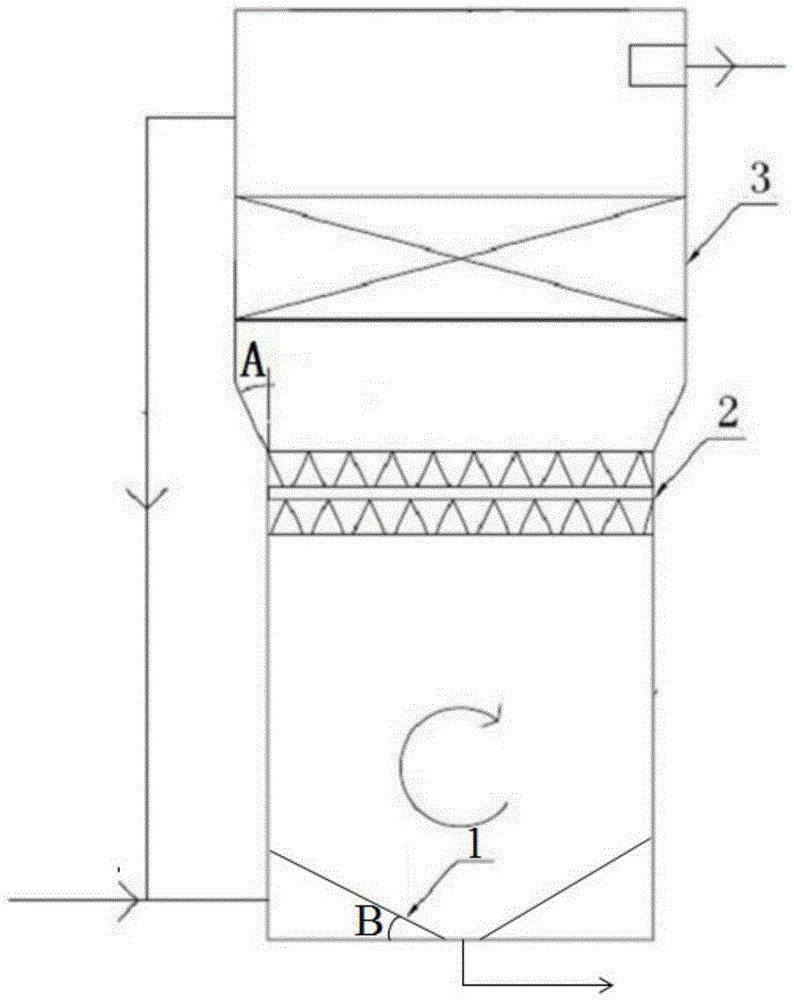

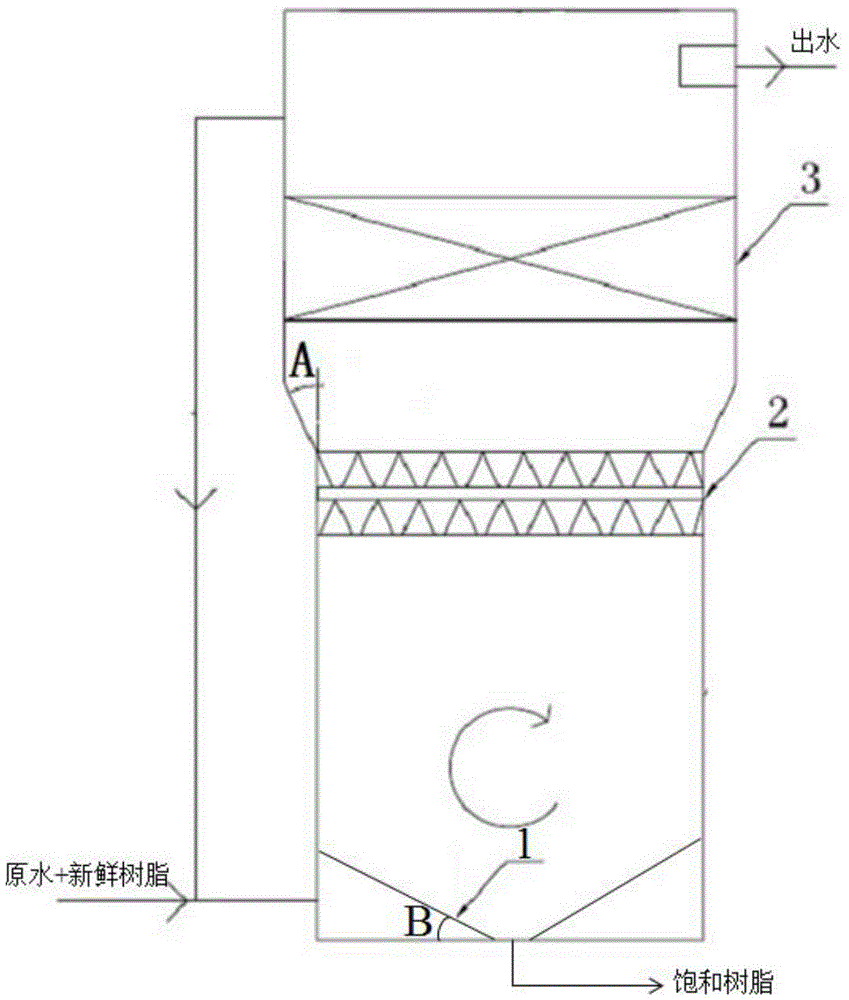

[0020] like figure 1 , an upflow reaction and separation integrated powder resin purifier, including swirl water distribution and concentration component 1, steady flow component 2 and particle separation component 3 three components, the purifier is formed from bottom to top in the reactor by the bottom There are four upward water and powder resin swirl reaction areas, powder resin-containing swirl water steady flow area, water and powder resin separation area, and purified water outlet area; among them, the swirl water distribution and concentration component 1 realizes swirl through symmetrical tangent water inlet design. The water is distributed by flowing water; the steady flow component 2 is provided with a double-layer reflection plate, and the upper part of the steady flow component 2 is provided with a particle separation component 3; as image 3 Shown: 20m per strand 3 / h Printing and dyeing wastewater biochemical treatment Tail water (COD about 80mg / L, chroma about...

Embodiment 2

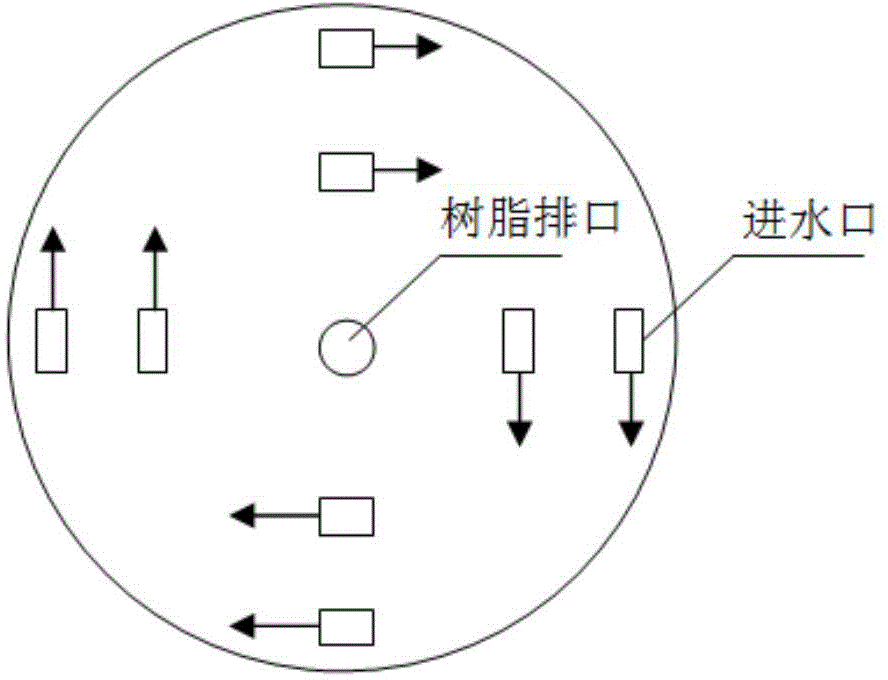

[0022] structured as figure 1 As shown, a strand of 20m 3 / h Printing and dyeing wastewater biochemical treatment Tail water (COD about 80mg / L, chroma about 45 times) is passed into the purifier figure 2 The swirling water distribution and concentration assembly 1, which is arranged symmetrically with eight horizontal tangents, is fully hydrocyclone-stirred at the bottom of the reactor with 10% volume concentration of powder resin with a particle size of 300 μm. After swirl reaction for 30 minutes, the resin-containing swirl The flowing water passes through the flow stabilization component 2 to slow down the turbulent flow of the water body, and then through the particle separation component 3 to realize the complete separation of the resin from the water. The separation area is 2.31m 2 , the angle A between the resin separation zone and the boundary of the reaction zone is 26 degrees, and the final separated water is discharged from the upper clear water zone, 10m 3 / h The...

Embodiment 3

[0024] structured as figure 1 As shown, a strand of 10m 3 / h Domestic sewage biochemical treatment tail water (COD about 50mg / L, chromaticity about 45 degrees) enters an upflow reaction and separation integrated powder resin purifier for purification reaction, and passes through twelve swirling flow cloths arranged symmetrically on horizontal tangent lines The water and concentration component 1 enter the purifier, and react at the bottom of the purifier with a 15% volume concentration of powdered resin with a particle size of 50 μm. After 15 minutes of swirl reaction, the resin-containing swirling water passes through the steady flow component 2 to slow down the turbulence of the water body, and then passes through the particle Separation module 3 realizes the complete separation of resin from water, and the separation area is 0.71m 2 , the angle A between the separation zone and the reaction zone boundary is 0 degrees, and the final separated water is discharged from the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com