In-situ generated flaky sialon-enhanced alumina-carbon refractory material and preparation method thereof

An aluminum-carbon refractory material, in-situ generation technology, applied in the field of sheet-like sialon-reinforced aluminum-carbon refractory materials, to achieve the effects of excellent fracture toughness, high normal temperature mechanical properties, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

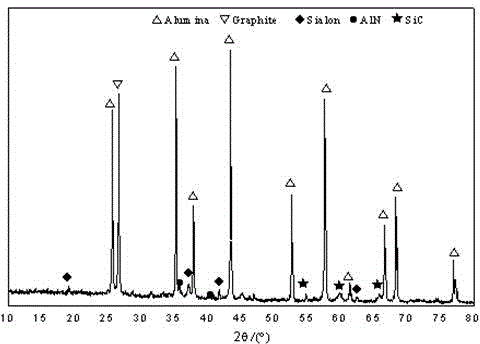

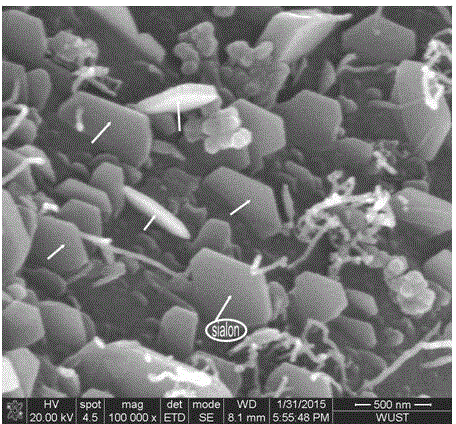

Image

Examples

Embodiment 1

[0034] An in-situ flaky sialon-reinforced aluminum-carbon refractory material and a preparation method thereof. First use 50~55wt% of corundum particles, 25~30wt% of corundum fine powder, 1~8wt% of activated alumina micropowder, 1~5wt% of carbon and 1~5wt% of antioxidant as raw materials, and add the 1~6wt% binder of raw materials, mixed and milled, trapped, molded, and dried; then kept in a reducing atmosphere at 1300~1450°C for 1~4 hours to obtain in-situ flaky sialon-reinforced aluminum-carbon refractories .

[0035] In this embodiment: the corundum particles are fused white corundum particles; the corundum fine powder is fused white corundum fine powder; the carbon is carbon black; the antioxidant is Si powder; Thermosetting liquid phenolic resin; the reducing atmosphere is a carbon-buried atmosphere.

Embodiment 2

[0037] An in-situ flaky sialon-reinforced aluminum-carbon refractory material and a preparation method thereof. Except following technical parameter, all the other are with embodiment 1.

[0038] In this embodiment: the corundum particles are alumina-based fused corundum particles; the corundum fine powder is alumina-based fused corundum fine powder; the carbon is graphite; the antioxidant is Al powder; The bonding agent is a thermoplastic phenolic resin; the reducing atmosphere is an atmosphere of buried graphite.

Embodiment 3

[0040] An in-situ flaky sialon-reinforced aluminum-carbon refractory material and a preparation method thereof. First use 50~55wt% of corundum particles, 25~30wt% of corundum fine powder, 1~8wt% of activated alumina micropowder, 1~5wt% of carbon and 1~5wt% of antioxidant as raw materials, and add the 1~6wt% binder of raw materials, mixed and milled, trapped, formed, and dried; then kept at 1450~1600°C for 3~6 hours in a nitrogen atmosphere to obtain in-situ flaky sialon-reinforced aluminum-carbon refractories .

[0041] In this embodiment: the corundum particles are a mixture of alumina-based fused corundum particles and fused white corundum particles; the corundum fine powder is a mixture of alumina-based fused corundum fine powder and fused white corundum fine powder; The carbon is a mixture of graphite and carbon black; the antioxidant is a mixture of Al powder and Si powder; the binding agent is a mixture of thermosetting liquid phenolic resin and thermoplastic phenolic r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com