Anti-floating agent, anti-floating controlled release urea and preparing method of anti-floating controlled release urea

A technology for controlled release of urea and anti-floating agent, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of poor anti-floating effect, water and soil pollution, large amount of anti-floating agent, etc. Inexpensive, increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

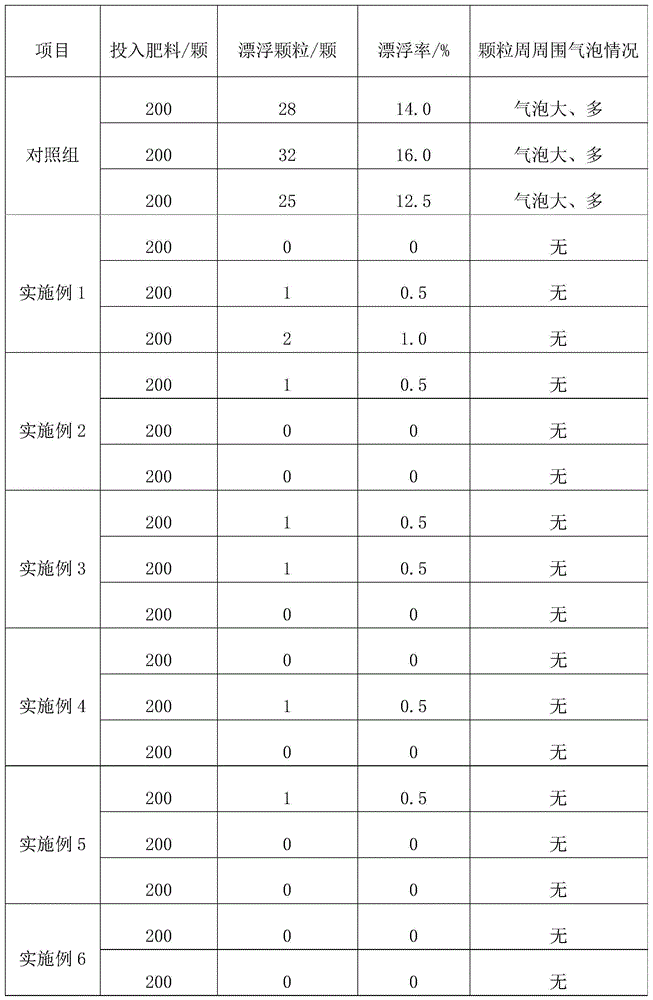

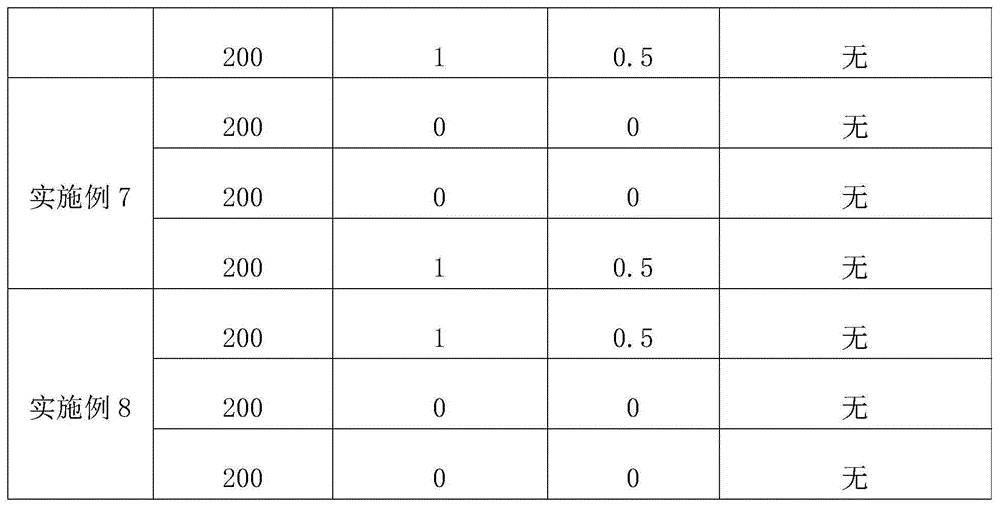

Examples

Embodiment 1

[0019] a. Core fertilizer equipment: sieve and classify the biodegradable coated controlled-release urea particles with a particle size of 2-4 mm, and dry them for later use.

[0020] B, the preparation of anti-floating agent: Alkyl polyglucoside (APG), sodium fatty alcohol polyoxyethylene ether carboxylate (AEC), coconut oil glucoside are compounded and mixed according to the mass ratio of 1.5:1.5:2 to obtain the The anti-floating agent mentioned above.

[0021] c. Load a total of 999.5 kg of screened controlled-release urea into drums or other forms of coating equipment.

[0022] d. Through the control of the flowmeter, a total of 0.5 kg of the anti-floating agent prepared in step b is sprayed onto the surface of the controlled-release urea particles quantitatively and evenly through the nozzle. Rotate the roller while spraying to ensure even mixing. The time for adding and mixing the anti-floating agent is 5-10 minutes, and the controlled-release urea granules after spray...

Embodiment 2

[0024] a. Core fertilizer equipment: sieve and classify the biodegradable coated controlled-release urea particles with a particle size of 2-4 mm, and dry them for later use.

[0025] B, the preparation of anti-floating agent: Alkyl polyglucoside (APG), sodium fatty alcohol polyoxyethylene ether carboxylate (AEC), coconut oil glucoside are compounded and mixed according to the mass ratio of 1.5:2:2 to obtain the The anti-floating agent mentioned above.

[0026] c. Load a total of 999.4 kg of screened controlled-release urea into drums or other forms of coating equipment.

[0027] d. Through the control of the flowmeter, a total of 0.6 kg of the anti-floating agent prepared in step b is sprayed onto the surface of the controlled-release urea particles quantitatively and evenly through the nozzle. Rotate the roller while spraying to ensure even mixing. The time for adding and mixing the anti-floating agent is 5-10 minutes, and the controlled-release urea granules after sprayin...

Embodiment 3

[0029] a. Core fertilizer equipment: sieve and classify the biodegradable coated controlled-release urea particles with a particle size of 2-4 mm, and dry them for later use.

[0030] B, the preparation of anti-floating agent: Alkyl polyglucoside (APG), sodium fatty alcohol polyoxyethylene ether carboxylate (AEC), coconut oil glucoside are compounded and mixed in a mass ratio of 1.5:2:3 to obtain the The anti-floating agent mentioned above.

[0031] c. Load a total of 999.2 kg of screened controlled-release urea into drums or other forms of coating equipment.

[0032] d. Through the control of the flowmeter, a total of 0.8 kg of the anti-floating agent prepared in step b is sprayed onto the surface of the controlled-release urea particles quantitatively and evenly through the nozzle. Rotate the roller while spraying to ensure even mixing. The time for adding and mixing the anti-floating agent is 5-10 minutes, and the controlled-release urea granules after spraying the anti-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com