Macromolecular fire retardant with P-N bond, preparation thereof and application of macromolecular fire retardant in polylactic acid

A polymer flame retardant, P-N technology, applied in the field of flame retardant, can solve the problems of poor compatibility, low molecular weight, easy migration, etc., and achieve the effect of reducing the reduction of flame retardant efficiency, reducing damage, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

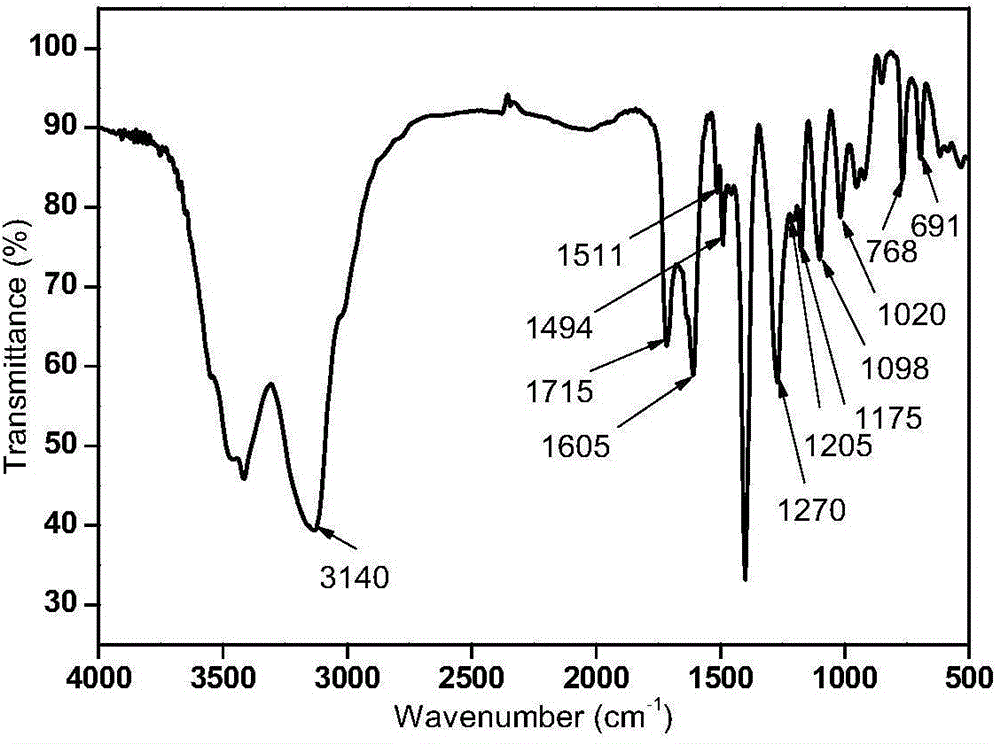

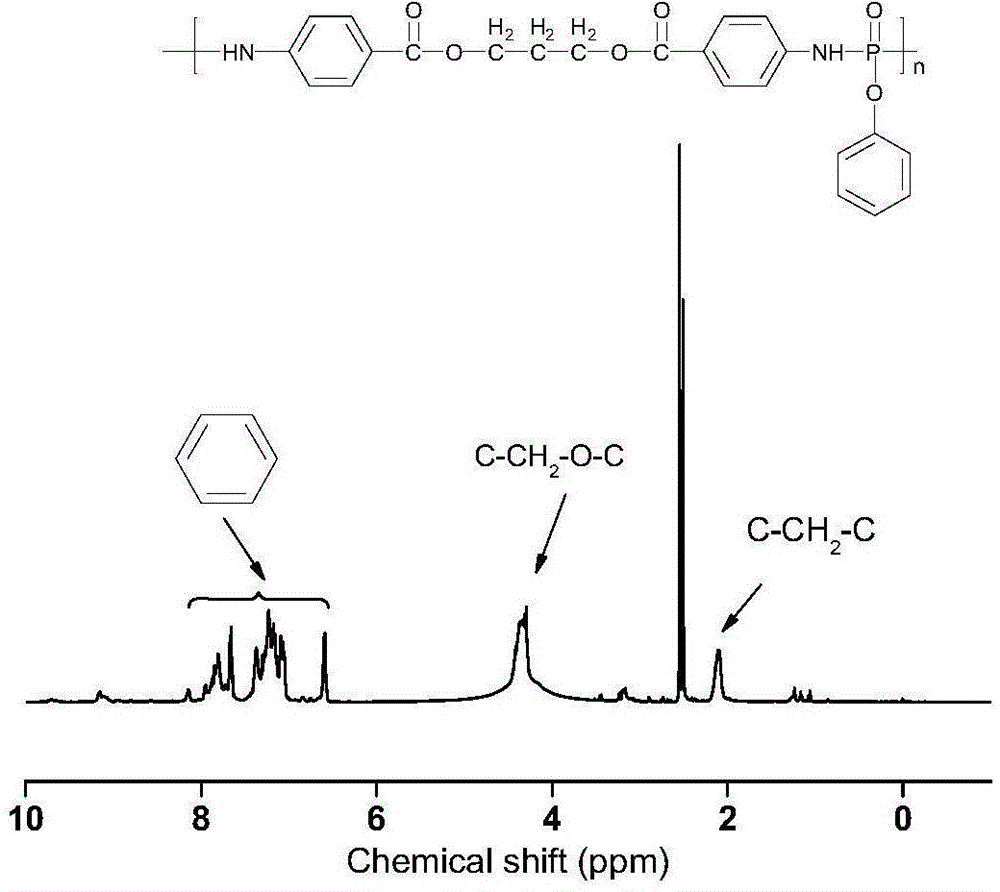

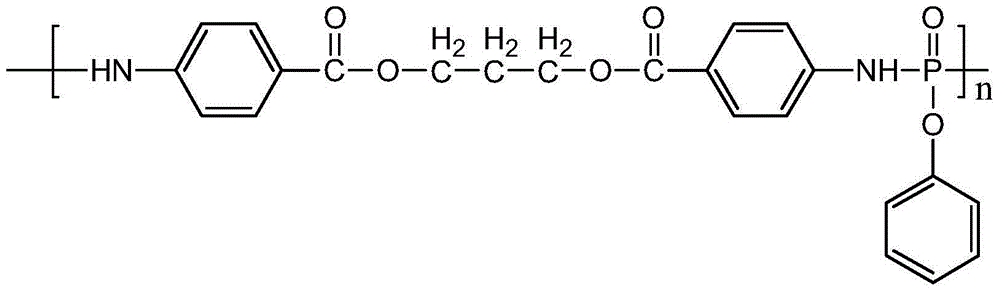

[0026] Embodiment 1: 1.60g 1,3-propanediol bis(4-aminobenzoate) and 1.01g triethylamine are dissolved in 25mL of chloroform treated with desiccant; 1,3-propanediol bis(4-aminobenzoate) Benzoic acid ester) and the chloroform solution of triethylamine move in the reactor, pass nitrogen protection, lead condensed water, stir, be heated to reflux temperature. Weigh 1.05g of phenyl dichlorophosphate and dissolve it in 5mL of dry chloroform, add the solution of phenyl dichlorophosphate in chloroform to the reactor drop by drop, keep the reaction at reflux temperature for 8h after the dropwise addition; after the reaction, remove by rotary evaporation Chloroform, the residue was dissolved in dimethyl sulfoxide, filtered to remove triethylamine hydrochloride, the filtrate was poured into a large amount of ethanol under stirring conditions to precipitate a white precipitate, filtered, washed three times with ethanol, and dried to obtain the high Molecular flame retardants. Its infrare...

Embodiment 2

[0031] Example 2: Weigh 38.8g of polylactic acid pellets, 1.2g of polymer flame retardant containing P-N bonds, and the extrusion temperature is 175°C in the first zone, 176°C in the second zone, 177°C in the third zone, and 177°C in the fourth zone. Under certain conditions, add a conical twin-screw extruder, extrude and cool to prepare a polymer flame retardant flame-retardant polylactic acid material containing P-N bonds. Measured according to the standard test method of GB / T2406-1993, the limiting oxygen index is 31.5%, and the crystallinity during cooling is 46.0%.

Embodiment 3

[0032] Example 3: Weigh 38g of polylactic acid pellets, 2g of polymer flame retardant containing P-N bonds, under the conditions that the extrusion temperature is 175°C in the first zone, 176°C in the second zone, 177°C in the third zone, and 177°C in the fourth zone , into a conical twin-screw extruder, extruded and cooled to obtain a polymer flame retardant flame retardant polylactic acid material containing P-N bonds. Measured according to the standard test method of GB / T2406-1993, the limiting oxygen index is 33.0%, and the crystallinity during cooling is 42.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com