Core-shell structure coating easy to clean and preparing method and application thereof

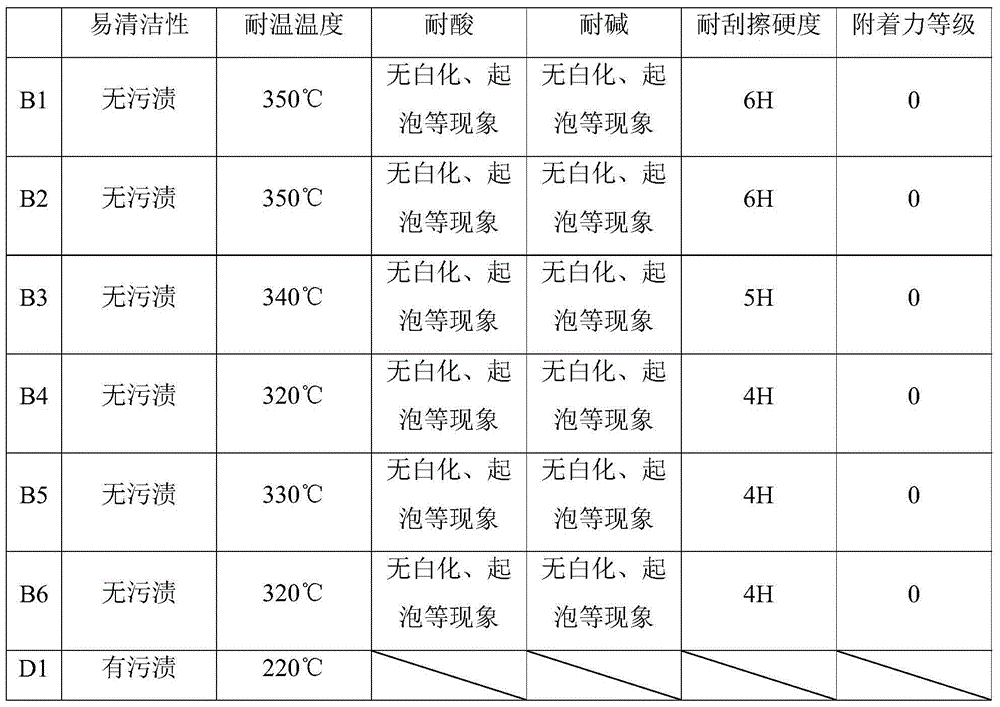

A core-shell structure and easy-to-clean technology, applied in coatings and other directions, can solve problems affecting performance, scratches and damage on the surface of materials, and achieve good stability, good acid and alkali resistance, and good temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] On the one hand, the present invention provides a kind of preparation method of core-shell structure easy-to-clean coating, and the method comprises:

[0028] (1) Mixing the nanoparticles and the alcohol solvent evenly under stirring, and adding a coupling agent under stirring to obtain the alcohol solution of the nanoparticle microsphere structure;

[0029] (2) Add an organic solvent to the alcohol solution of the nanoparticle microsphere structure obtained in step (1), under an inert atmosphere, at 15-50 ° C, add the initiator for the first time under stirring, and then heat up to 60- At 105°C, add silicon-containing monomers, fluorine-containing monomers, ester monomers and dispersants, and then add the initiator for the second time to carry out the reaction. After the reaction, cool to room temperature.

[0030] In the present invention, for the convenience of preparation, the method of the present invention can be carried out in a reaction bottle.

[0031] Step (1...

Embodiment 1

[0055] This example is used to illustrate the core-shell structure easy-to-clean coating of the present invention and its preparation method.

[0056] (1) Mix 6 parts by weight of silica nanoparticles (purchased from Suzhou NordPayson Pharmaceutical Technology Co., Ltd., FNP10026, the same below) with 6 parts by weight of ethanol solvent into the reaction bottle, and stir at 150rpm Make it mix evenly; Slowly add 1 weight part of isocyanate propyltriethoxysilane (purchased from Nanjing Chengong Organic Silicon Material Co., Ltd., CG-907, the same below) to the reaction flask under high-speed stirring at 150rpm , to obtain the ethanol solution of silica nanoparticle microsphere structure;

[0057] (2) Add 13.5 parts by weight of toluene and 20 parts by weight of acetone to the ethanol solution of the silicon dioxide nanoparticle microsphere structure obtained in step (1), under a nitrogen atmosphere, at 50 ° C, stir while stirring at 120 rpm While adding 0.05 parts by weight of...

Embodiment 2

[0059] This example is used to illustrate the core-shell structure easy-to-clean coating of the present invention and its preparation method.

[0060] (1) 8 parts by weight of titanium dioxide nanoparticles (purchased from Suzhou NordPayson Pharmaceutical Technology Co., Ltd., FNP10025, the same below) are mixed with 8 parts by weight of isopropanol solvent into the reaction bottle, and stirred at a high speed of 160rpm Make it mix evenly; Slowly add 1.3 parts by weight of diphenyldimethoxysilane (purchased from Nanjing Chengong Organosilicon Materials Co., Ltd., CG-P213) to the reaction flask afterward under high-speed stirring at 160rpm to obtain titanium dioxide nanoparticles Isopropanol solution of microsphere structure;

[0061] (2) Add 23.3 parts by weight of acetone in the isopropanol solution of the titanium dioxide nanoparticle microsphere structure obtained in step (1), under a nitrogen atmosphere, at 35° C., add 0.07 parts by weight of acetone while stirring at 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com