Martensite broad hot strip with tensile strength of 1500MPa level and production method of martensite broad hot strip

A technology of tensile strength and production method, which is applied in the field of metallurgy, can solve problems such as short residence time and increased difficulty in controlling the microstructure of finished products, and achieve the effects of simplifying processing steps, saving processing time and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

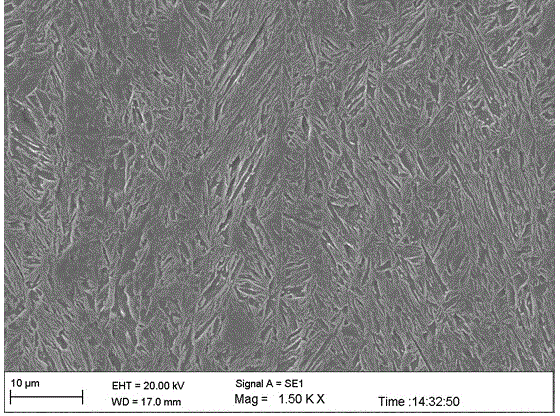

Image

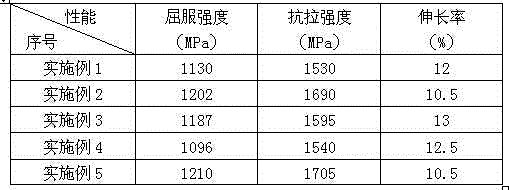

Examples

Embodiment 1

[0028] Tensile strength 1500MPa grade martensitic hot-rolled wide strip steel, chemical composition and weight percentage content: C: 0.14%, Si: 0.46%, Mn: 1.35%, P: 0.011%, S: 0.003%, Nb: 0.020 %, Ti: 0.03%, B: 0.0012%, Als: 0.017%, N: 0.0036%, and the balance is Fe and unavoidable impurity elements.

[0029] The production method comprises the following steps:

[0030] 1) The molten steel is smelted according to the above-mentioned composition, and the molten steel is subjected to RH vacuum degassing and continuous casting to obtain a slab;

[0031] 2) Heating the slab to 1265°C, descaling with 19MPa high-pressure water, rough rolling after 5 passes of rolling, the exit temperature is 1105°C, coiled by a hot coil box, and finishing rolling with 7 rolling mills. The rolling inlet temperature is 1075°C, and the outlet temperature is 890°C; laminar cooling is performed at a cooling rate of 75°C / S, and hot-rolled wide strips are obtained from coils at 153°C.

Embodiment 2

[0033] Tensile strength 1500MPa grade martensitic hot-rolled wide strip steel, chemical composition and weight percentage content: C: 0.17%, Si: 0.54%, Mn: 1.53%, P: 0.009%, S: 0.003%, Nb: 0.034 %, Ti: 0.048%, B: 0.0029%, Als: 0.031%, N: 0.0044%, and the balance is Fe and unavoidable impurity elements.

[0034] The production method comprises the following steps:

[0035] 1) The molten steel is smelted according to the above-mentioned composition, and the molten steel is subjected to RH vacuum degassing and continuous casting to obtain a slab;

[0036] 2) Heating the slab to 1293°C, descaling with 19MPa high-pressure water, rough rolling after 5 passes of rolling, the exit temperature is 1133°C, coiled by a hot coil box, and finishing rolling with 7 rolling mills. The rolling inlet temperature is 1100°C, and the exit temperature is 916°C; the speed is 77°C / S for laminar cooling, and the coil is obtained at 140°C to obtain a hot-rolled wide strip.

Embodiment 3

[0038] Tensile strength 1500MPa grade martensitic hot-rolled wide strip steel, chemical composition and weight percentage content: C: 0.15%, Si: 0.45%, Mn: 1.41%, P: 0.007%, S: 0.004%, Nb: 0.031 %, Ti: 0.040%, B: 0.0020%, Als: 0.021%, N: 0.0032%, and the balance is Fe and unavoidable impurity elements.

[0039] The production method comprises the following steps:

[0040] 1) The molten steel is smelted according to the above-mentioned composition, and the molten steel is subjected to RH vacuum degassing and continuous casting to obtain a slab;

[0041] 2) Heating the slab to 1282°C, descaling with 18MPa high-pressure water, rough rolling after 5 passes of rolling, the exit temperature is 1122°C, coiled by a hot coil box, and finishing rolling with 7 rolling mills. The rolling entrance temperature is 1092°C, the exit temperature is 902°C; the speed is 70°C / S for laminar cooling, and the coil is obtained at 190°C to obtain a hot-rolled wide strip.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com