A method and device for manufacturing a surface modification layer of a metal material

A surface modification layer and metal material technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve problems such as easy transfer or wear, parts damage, equipment instability, etc., to reduce the friction coefficient , long wear life, improved lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

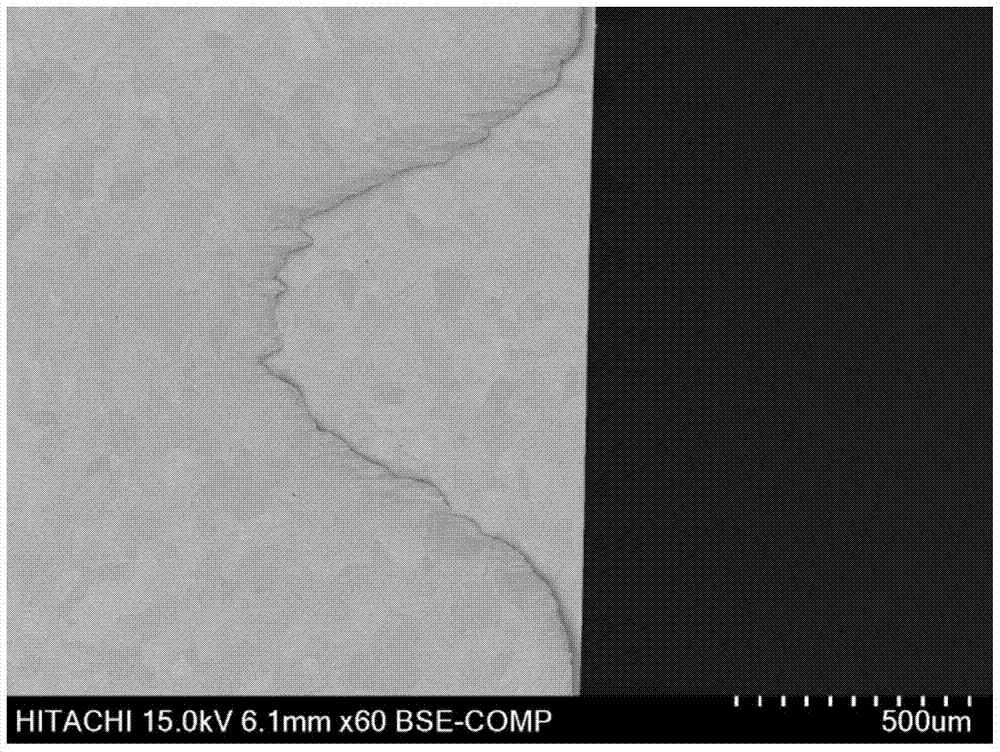

[0036] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

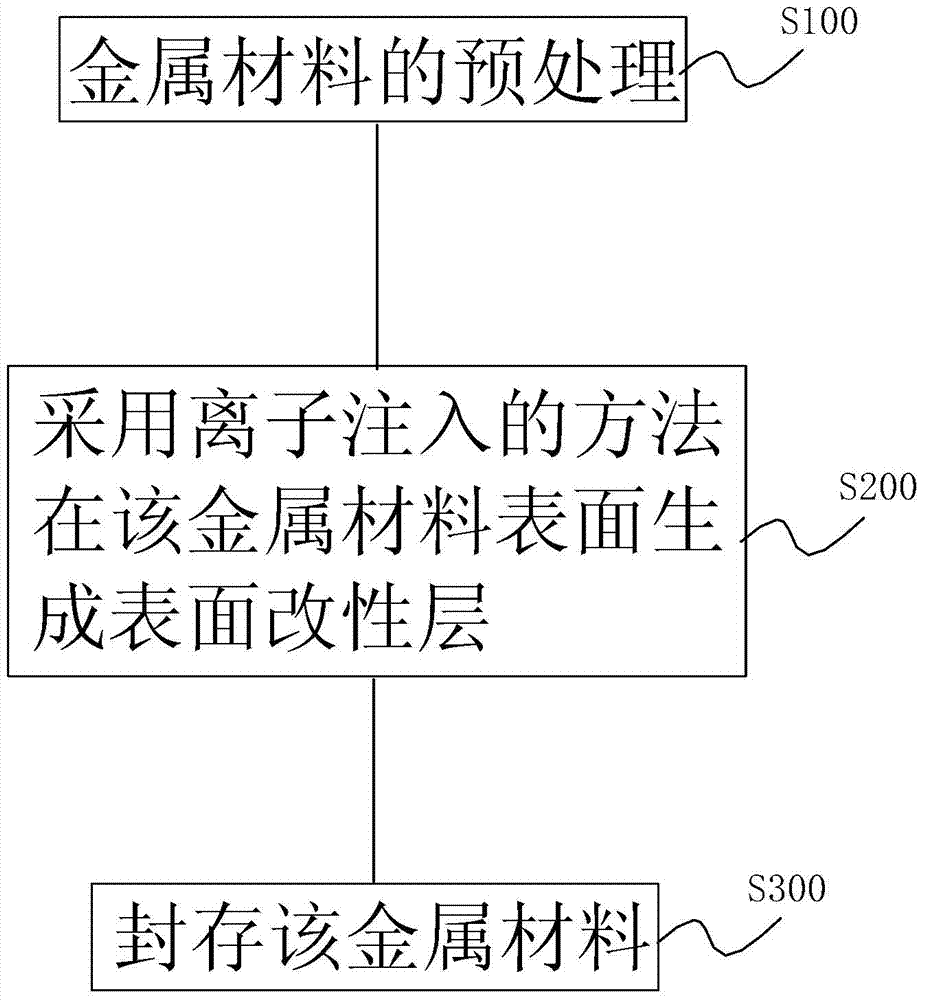

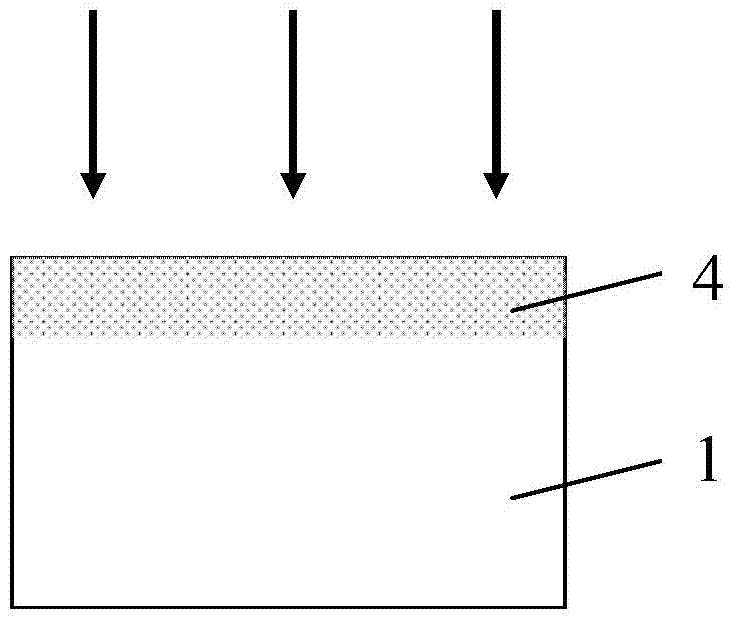

[0037] see figure 1 , figure 1 It is a flow chart of the manufacturing method of the present invention. The manufacture method of metal material surface modification layer of the present invention adopts ion implantation method to WS 2 The surface modification of the metal material 1 for the target includes the following steps:

[0038] Step S100, pretreatment of the metal material 1, performing pretreatment on the metal material 1 to be processed to remove grease, rust spots and impurities attached to the surface of the metal material 1;

[0039] The step S100 includes:

[0040] S101, remove the surface grease of the metal material 1, and remove the metal material with a metal degreasing solvent (such as sodium hydroxide, sodium carbonate, sodium phosphate decahydrate, sodium silicate, detergent, corrosion inhibitor, solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com