Patents

Literature

46results about How to "No bonding issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for strengthening compounding of TiN on laser-induced metal surface layer by taking TiO2, urea and N2 as components

The invention discloses a method for strengthening the compounding of TiN on a laser-induced metal surface layer by taking TiO2, urea and N2 as components and relates to the technical field of metal surface strengthening processes. The method comprises the following steps of: coating the mixed powder of TiO2 and the urea on a metal surface; and scanning on the metal surface by using a laser beam at the N2 atmosphere, wherein the mixed powder of TiO2 and the urea is coated on the metal surface. Through the method, TiN can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:路亚科消防车辆制造有限公司

Method for strengthening compounding of TiC on laser-induced metal surface layer by taking TiO2 and methane as components

ActiveCN102995004ANo bonding issuesHigh hardnessMetallic material coating processesSurface layerWear resistance

The invention discloses a method for strengthening the compounding of TiC on a laser-induced metal surface layer by taking TiO2 and methane as components and relates to the technical field of metal surface strengthening. The method comprises the following steps of: coating TiO2 powder on a metal surface; and scanning on the TiO2 powder coated metal surface by using a laser beam at the methane atmosphere. Through the method, TiC can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:路亚科消防车辆制造有限公司

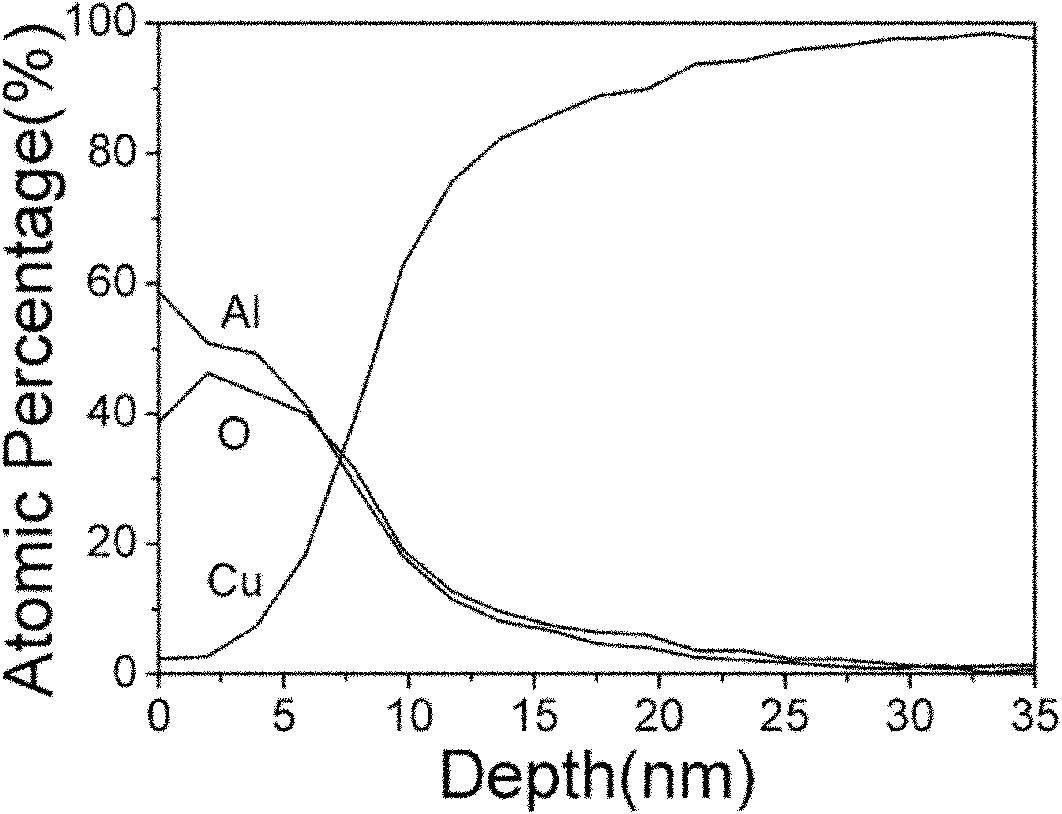

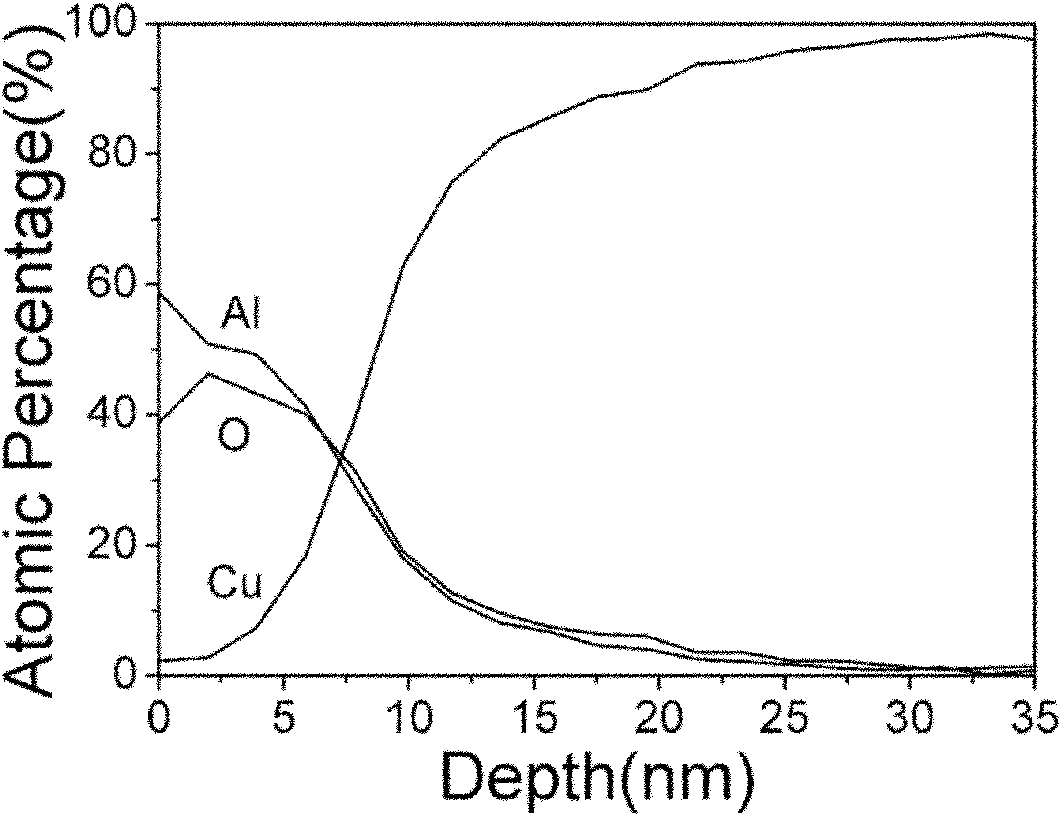

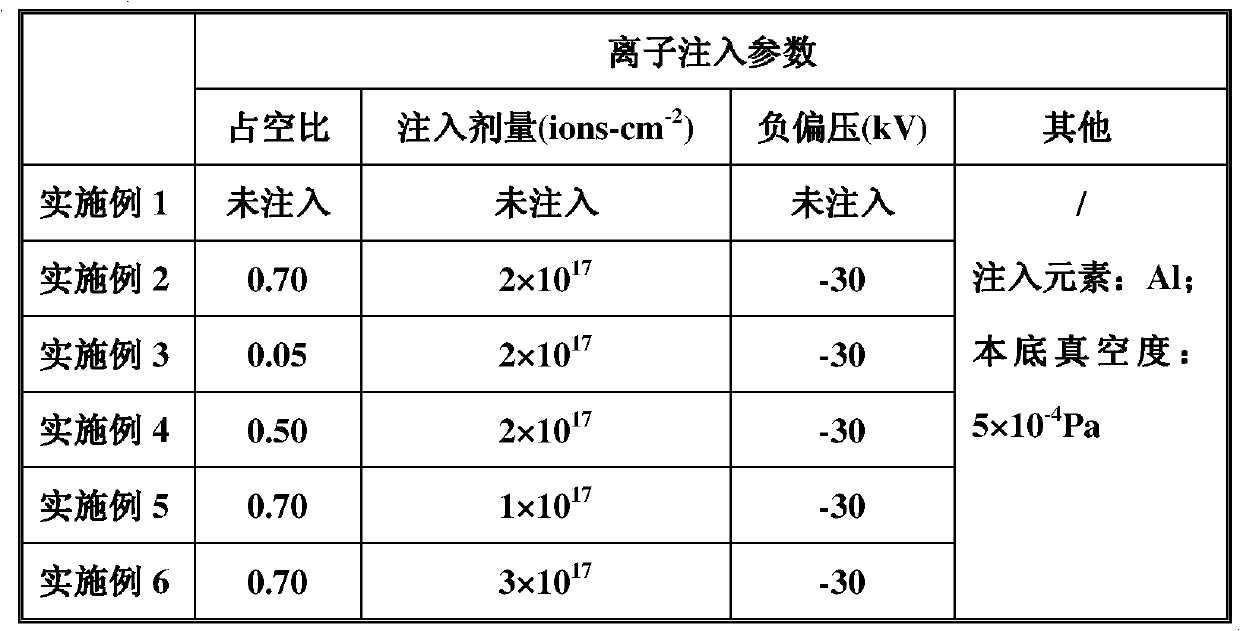

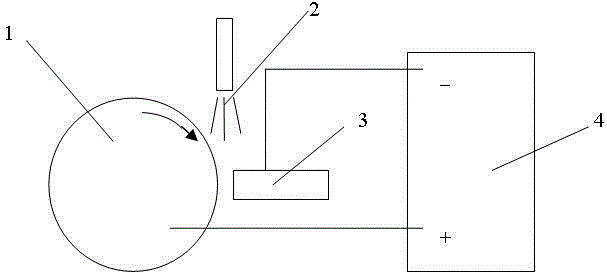

Plasma immersion ion injection method for improving anti-oxidation property of copper film

InactiveCN101921991AHigh purityPromote environmental protectionVacuum evaporation coatingSputtering coatingOrganic solventOxidation resistant

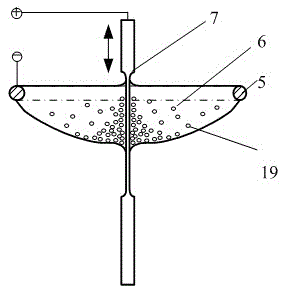

The invention discloses a plasma immersion ion injection method for improving anti-oxidation property of a copper film in the technical field of material surface solidification, which comprises the following steps of: ultrasonically washing a plurality of glass substrates with de-ionized water and an organic solvent in sequence and drying for latter use; fixing the washed glass substrates on a sample platform of magnetron sputtering equipment and preparing the copper film by using a deposition process; and taking out the uniform copper film obtained by deposition and placing the uniform copper film on plasma immersion ion injection equipment, performing ion injection treatment by using a metal rod as a target source, and oxidizing the obtained copper film in a heating furnace. The plasma immersion ion injection method can obviously improve the anti-oxidation property of the copper film and avoid the problem on the bonding force of film bases between a modified layer and the copper film; and plasma ion immersion injection technology is novel and highly environmentally-friendly material surface modification technology, and magnetron sputtering technology for preparing the copper film is also nuisanceless film deposition technology, so that the plasma immersion ion injection method is highly environmentally-friendly.

Owner:SHANGHAI JIAO TONG UNIV

Strengthening method for compounding TiN on metal surface layer by inducing through laser overlying tungsten electrode gas-shielded arc

ActiveCN102995009AHigh hardnessImprove wear resistanceMetallic material coating processesSurface layerWear resistance

The invention relates to a strengthening method for compounding TiN on a metal surface layer by taking TiO2, carbamide and N2 gas as components and inducing through a laser overlying tungsten electrode gas-shielded arc, relating to the technical field of metal surface strengthening treatment. TiO2 and carbamide mixed powder is coated on a metal surface, and the metal surface coated with the TiO2 and carbamide mixed powder is scanned by using the laser overlying tungsten electrode gas-shielded arc. The strengthening method disclosed by the invention can be used for generating the TiN on the metal surface layer in a in-situ compounding way, thereby strengthening the metal surface and enhancing the abrasion resistance.

Owner:海安超明新材料有限公司

Reinforcing method for compositing TiN on metal surface layer induced by laser superposed tungsten electrode gas-shielded arc

ActiveCN103014702AHigh hardnessImprove wear resistanceMetallic material coating processesSurface layerWear resistance

The invention discloses a reinforcing method for compositing TiN on a metal surface layer induced by a laser superposed tungsten electrode gas-shielded arc, and relates to the technical field of reinforcing treatment on a metal surface. The reinforcing method takes TiO2 and N2 as components. TiO2 powder is coated on the metal surface, and the laser superposed tungsten electrode gas-shielded arc is used to scan the metal surface coated by the TiO2 powder in an N2 atmosphere. According to the reinforcing method, TiN is generated on the metal surface layer in an in-situ composite manner; the metal surface is reinforced; and the wear resistance of the metal surface is improved.

Owner:路亚科消防车辆制造有限公司

Laser induced metal surface layer composite TiCN reinforcing method with TiO2, formamide, carbon black, acetylene and nitrogen gas as components

ActiveCN102978606ANo bonding issuesHigh hardnessHeat inorganic powder coatingCarbon blackNitrogen gas

The invention discloses a laser induced metal surface layer composite TiCN reinforcing method with TiO2, formamide, carbon black, acetylene and nitrogen gas as components, and relates to the technical field of metal surface reinforcement processing. The method comprises the following steps: applying TiO2, formamide and carbon black mixture on a metal surface, and under acetylene and nitrogen gas existing condition, scanning with laser beams on the metal surface to which the mixture is applied. By adopting the above method, TiCN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:路亚科消防车辆制造有限公司

Strengthening method of laser-induced metal surface layer composite TiCN

ActiveCN103046043ATo achieve reinforcementImprove wear resistanceSolid/suspension decomposition chemical coatingHeat inorganic powder coatingSurface layerNitrogen

The invention relates to the technical field of metal surface strengthening and discloses a strengthening method of laser-induced metal surface layer composite TiCN, which comprises the components of TiO2, tetramethyl urea, carbon black, acetylene and nitrogen. The method comprises the steps that the metal surface is coated with a mixture of TiO2, tetramethyl urea and carbon black, and under the condition that acetylene and nitrogen coexist, laser beams are used for scanning the metal surface coated with the mixture. With the adoption of the method, TiCN can be generated on the metal surface layer in an in-situ composite manner, so that the strengthening of the metal surface is realized, and the wear-resisting performance is improved.

Owner:海安华诚新材料有限公司

Laser-induced reinforcing method for compositing TiCN on metal surface layer

ActiveCN103014698ANo bonding issuesHigh hardnessMetallic material coating processesSurface layerNitrogen

The invention discloses a laser-induced reinforcing method for compositing TiCN on a metal surface layer, and relates to the technical field of reinforcement of a metal surface. The reinforcing method takes TiO2, tetramethyl urea, carbon black, methane and nitrogen as components. A mixture of TiO2, tetramethyl urea and carbon black is coated on the metal surface; and laser beams are used for scanning the metal surface coated with the mixture under the condition that methane and nitrogen coexist. According to the reinforcing method, TiCN is generated on the metal surface layer in an in-situ composite manner; the metal surface is reinforced; and the wear resistance of the metal surface is improved.

Owner:路亚科消防车辆制造有限公司

Laser induced metal surface layer composite TiN reinforcing method with TiO2 and N2 gas as components

ActiveCN102978612ANo bonding issuesHigh hardnessMetallic material coating processesProduct gasLaser beams

The invention discloses a laser induced metal surface layer composite TiN reinforcing method with TiO2 and N2 gas as components, and relates to the technical field of metal surface reinforcement process. The method comprises the following steps: applying TiO2 powder on a metal surface, and in N2 gas atmosphere, scanning with laser beams on the metal surface to which the TiO2 powder is applied. By adopting the above method, TiCN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:路亚科消防车辆制造有限公司

Method for strengthening compounding of TiN on laser-induced metal surface layer by taking TiO2, urea and N2 as components

ActiveCN102995011BNo bonding issuesHigh hardnessMetallic material coating processesSurface layerWear resistance

The invention discloses a method for strengthening the compounding of TiN on a laser-induced metal surface layer by taking TiO2, urea and N2 as components and relates to the technical field of metal surface strengthening processes. The method comprises the following steps of: coating the mixed powder of TiO2 and the urea on a metal surface; and scanning on the metal surface by using a laser beam at the N2 atmosphere, wherein the mixed powder of TiO2 and the urea is coated on the metal surface. Through the method, TiN can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:路亚科消防车辆制造有限公司

Method for strengthening compounding of TiC on laser-induced metal surface layer by taking TiO2, carbon black and acetylene as components

ActiveCN102995006ANo bonding issuesHigh hardnessMetallic material coating processesSurface layerWear resistance

The invention discloses a method for strengthening the compounding of TiC on a laser-induced metal surface layer taking TiO2, carbon black and acetylene as components and relates to the technical field of metal surface strengthening. The method comprises the following steps of: coating the mixed powder of TiO2 and the carbon black on a metal surface; and scanning on the metal surface by using a laser beam at the acetylene atmosphere, wherein the mixed powder of TiO2 and the carbon black is coated on the metal surface. Through the method, TiC can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:路亚科消防车辆制造有限公司

Ion arc induced metal surface layer composite TiN reinforcing method with TiO2 and N2 gas as components

ActiveCN102978615BNo bonding issuesHigh hardnessMetallic material coating processesSurface layerProduct gas

The invention discloses an ion arc induced metal surface layer composite TiN reinforcing method with TiO2 and N2 gas as components, and relates to the technical field of metal surface reinforcement processing. The method comprises the following steps: applying TiO2 powder on a metal surface, and in N2 gas atmosphere, scanning with plasma arcs on the metal surface to which the TiO2 powder is applied. By adopting the above method, TiN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:山东润蒙应急救援装备有限公司

Laser-induced wheel pair surface strengthening and finishing processing method

ActiveCN104827146ANo bonding issuesCreate pollutionMetal working apparatusHeat inorganic powder coatingNitrogen gasLaser beams

The invention discloses a laser-induced wheel pair surface strengthening and finishing processing method so as to solve the problems of small microhardness, poor wear resistance, large surface roughness, long production period and severe environment pollution and the like in a conventional wheel pair manufacture process. The method comprises the following steps: 1) the wheel pair surface strengthening step: mixed powders formed by TiO2, formamide and carbon black are input with nitrogen and acetylene and the mixed powders are blown; laser beams slantly radiate the mixed powders and the nitrogen; and a wheel is rotatably arranged in the nitrogen and acetylene gas atmosphere, and Ti (C, N) is generated on a wheel pair metal surface through in-situ composite; and 2) the wheel pair finishing processing step: a neutral electrolyte is input between the wheel obtained after the laser-induced strengthening and a cathode, a clamp plate clamps the wheel to rotate, and the cathode carries out feed movement simultaneously, and finishing process is carried out on the surface of the wheel pair through the pulse electrochemical technology. The method enhances wheel pair hardness, improves surface wear resistance, reduces surface roughness and improves fatigue life.

Owner:JIANGSU HUAYAO MACHINERY MFG

Laser-Induced Metal Surface Composite Tin Strengthening Method Using tio2 and n2 Gases as Components

ActiveCN102978612BNo bonding issuesHigh hardnessMetallic material coating processesWear resistanceLaser beams

The invention discloses a laser induced metal surface layer composite TiN reinforcing method with TiO2 and N2 gas as components, and relates to the technical field of metal surface reinforcement process. The method comprises the following steps: applying TiO2 powder on a metal surface, and in N2 gas atmosphere, scanning with laser beams on the metal surface to which the TiO2 powder is applied. By adopting the above method, TiCN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:路亚科消防车辆制造有限公司

Method for strengthening compounding of TiC on laser-induced metal surface layer by taking TiO2, carbon black and acetylene as components

ActiveCN102995006BNo bonding issuesHigh hardnessMetallic material coating processesSurface layerWear resistance

The invention discloses a method for strengthening the compounding of TiC on a laser-induced metal surface layer taking TiO2, carbon black and acetylene as components and relates to the technical field of metal surface strengthening. The method comprises the following steps of: coating the mixed powder of TiO2 and the carbon black on a metal surface; and scanning on the metal surface by using a laser beam at the acetylene atmosphere, wherein the mixed powder of TiO2 and the carbon black is coated on the metal surface. Through the method, TiC can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:路亚科消防车辆制造有限公司

Laser-induced metal surface composite TICN strengthening method with tio2, dimethylamine, carbon black, methane and nitrogen as components

ActiveCN102995008BNo bonding issuesHigh hardnessMetallic material coating processesSurface layerNitrogen

The invention discloses a method for strengthening the compounding of TiCN on a laser-induced metal surface layer by taking TiO2, dimethylamine, carbon black, methane and nitrogen as components and relates to the technical field of metal surface strengthening. The method comprises the following steps of: coating the mixture of TiO2, the dimethylamine and the carbon black on a metal surface; and scanning on the mixture-coated metal surface by using a laser beam under the condition that methane and nitrogen coexist. Through the method, TiCN can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:路亚科消防车辆制造有限公司

Ion arc induced metal surface layer composite TiN reinforcing method with TiO2, urea and N2 gas as components

ActiveCN102978605BNo bonding issuesHigh hardnessHeat inorganic powder coatingSurface layerWear resistance

The invention discloses an ion arc induced metal surface layer composite TiN reinforcing method with TiO2, urea and N2 gas as components, and relates to the technical field of metal surface reinforcement processing. The method comprises the following steps: applying TiO2 and urea mixed powder on a metal surface, and in N2 gas atmosphere, scanning with plasma arcs on the metal surface to which the TiO2 and urea mixed powder is applied. By adopting the above method, TiN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:路亚科消防车辆制造有限公司

A Laser Induced Metal Surface Composite TICN Strengthening Method

ActiveCN103046043BNo bonding issuesHigh hardnessSolid/suspension decomposition chemical coatingHeat inorganic powder coatingSurface layerNitrogen

The invention relates to the technical field of metal surface strengthening and discloses a strengthening method of laser-induced metal surface layer composite TiCN, which comprises the components of TiO2, tetramethyl urea, carbon black, acetylene and nitrogen. The method comprises the steps that the metal surface is coated with a mixture of TiO2, tetramethyl urea and carbon black, and under the condition that acetylene and nitrogen coexist, laser beams are used for scanning the metal surface coated with the mixture. With the adoption of the method, TiCN can be generated on the metal surface layer in an in-situ composite manner, so that the strengthening of the metal surface is realized, and the wear-resisting performance is improved.

Owner:海安华诚新材料有限公司

Laser induced metal surface layer composite TiCN reinforcing method with TiO2, acetamide, carbon black, acetylene and nitrogen gas as components

ActiveCN102978603BNo bonding issuesHigh hardnessHeat inorganic powder coatingSurface layerNitrogen gas

The invention discloses a laser induced metal surface layer composite TiCN reinforcing method with TiO2, acetamide, carbon black, acetylene and nitrogen gas as components, and relates to the technical field of metal surface reinforcement process. The method comprises the following steps: applying TiO2, acetamide and carbon black mixture on a metal surface, and under acetylene and nitrogen gas coexisting condition, scanning with laser beams on the metal surface to which the mixture is applied. By adopting the above process, TiCN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:山东格新精工有限公司

Ion arc induced metal surface layer composite TiN reinforcing method with TiO2, urea and N2 gas as components

ActiveCN102978605ANo bonding issuesHigh hardnessHeat inorganic powder coatingSurface layerWear resistance

The invention discloses an ion arc induced metal surface layer composite TiN reinforcing method with TiO2, urea and N2 gas as components, and relates to the technical field of metal surface reinforcement processing. The method comprises the following steps: applying TiO2 and urea mixed powder on a metal surface, and in N2 gas atmosphere, scanning with plasma arcs on the metal surface to which the TiO2 and urea mixed powder is applied. By adopting the above method, TiN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:路亚科消防车辆制造有限公司

Laser induced metal surface layer composite TiC reinforcing method with TiO2 and acetylene as components

ActiveCN102978613ANo bonding issuesHigh hardnessMetallic material coating processesSurface layerWear resistance

The invention discloses a laser induced metal surface layer composite TiC reinforcing method with TiO2 and acetylene as components, and relates to the technical field of metal surface reinforcement. The method comprises the following steps: applying TiO2 powder on a metal surface, and in acetylene atmosphere, scanning with laser beams on the metal surface to which the TiO2 powder is applied. By adopting the above method, TiCN can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:山东润蒙应急救援装备有限公司

Laser-induced metal surface composite TICN strengthening method with tio2, isopropylamine, carbon black, acetylene and nitrogen as components

InactiveCN102995007BNo bonding issuesHigh hardnessMetallic material coating processesSurface layerNitrogen

The invention discloses a method for strengthening the compounding of TiCN on a laser-induced metal surface layer by taking TiO2, isopropyl amine, carbon black, acetylene and nitrogen as components and relates to the technical field of metal surface strengthening treatment. The method comprises the following steps of: coating the mixture of the TiO2, the isopropyl amine and the carbon black on a metal surface; and scanning on the mixture-coated metal surface by using a laser beam under the condition that the acetylene and the nitrogen gas coexist. Through the method, TiCN can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:NANTONG HUAGONG MACHINERY

Metal surface compound TiN strengthening method induced by laser beam combination gas tungsten arcs

ActiveCN103046047AHigh hardnessImprove wear resistanceMetallic material coating processesWear resistanceLaser beams

The invention relates to the field of metal surface strengthening processing techniques, in particular to a metal surface compound TiN strengthening method induced by laser beam combination gas tungsten arcs using TiO2, ammonium carbonate, N2 gas as components. The method comprises the following steps: the metal surface is coated with mixed powder of TiO2 and ammonium carbonate; and the metal surface coasted with the mixed powder of TiO2 and ammonium carbonate is scanned by laser beam combination gas tungsten arcs in an N2 gas atmosphere. According to the method, TiN is in-situ composited on the metal surface to strengthen the metal surface and improve the wearing resistance of the metal surface.

Owner:海安超明新材料有限公司

Method for strengthening laser induced metal surface layer composite TiCN by using TiO2, isopropylamine, carbon black, methanol and nitrogen as components

ActiveCN102995005ATo achieve reinforcementImprove wear resistanceMetallic material coating processesSurface layerNitrogen

The invention discloses a method for strengthening a laser induced metal surface layer composite TiCN by using TiO2, isopropylamine, carbon black, methanol and nitrogen as components, and relates to the technical field of strengthening treatment on metal surfaces. A mixture of the TiO2, the isopropylamine and carbon black is applied to the metal surface, and the metal surface applied with the mixture is scanned by a laser beam in a co-existence of the methanol and the nitrogen. By adopting the method, TiCN is generated by in-situ compounding of the metal surface layer, so that the strengthening to the metal surface and the abrasion resistance are realized.

Owner:NANTONG BEST MACHINE CO LTD

Method for strengthening compounding of TiCN on laser-induced metal surface layer taking TiO2, dimethylamine, carbon black, methane and nitrogen as components

ActiveCN102995008ANo bonding issuesHigh hardnessMetallic material coating processesSurface layerNitrogen

The invention discloses a method for strengthening the compounding of TiCN on a laser-induced metal surface layer by taking TiO2, dimethylamine, carbon black, methane and nitrogen as components and relates to the technical field of metal surface strengthening. The method comprises the following steps of: coating the mixture of TiO2, the dimethylamine and the carbon black on a metal surface; and scanning on the mixture-coated metal surface by using a laser beam under the condition that methane and nitrogen coexist. Through the method, TiCN can be generated on the metal surface layer through in-situ compounding so that the metal surface is strengthened and the wear resistance is improved.

Owner:路亚科消防车辆制造有限公司

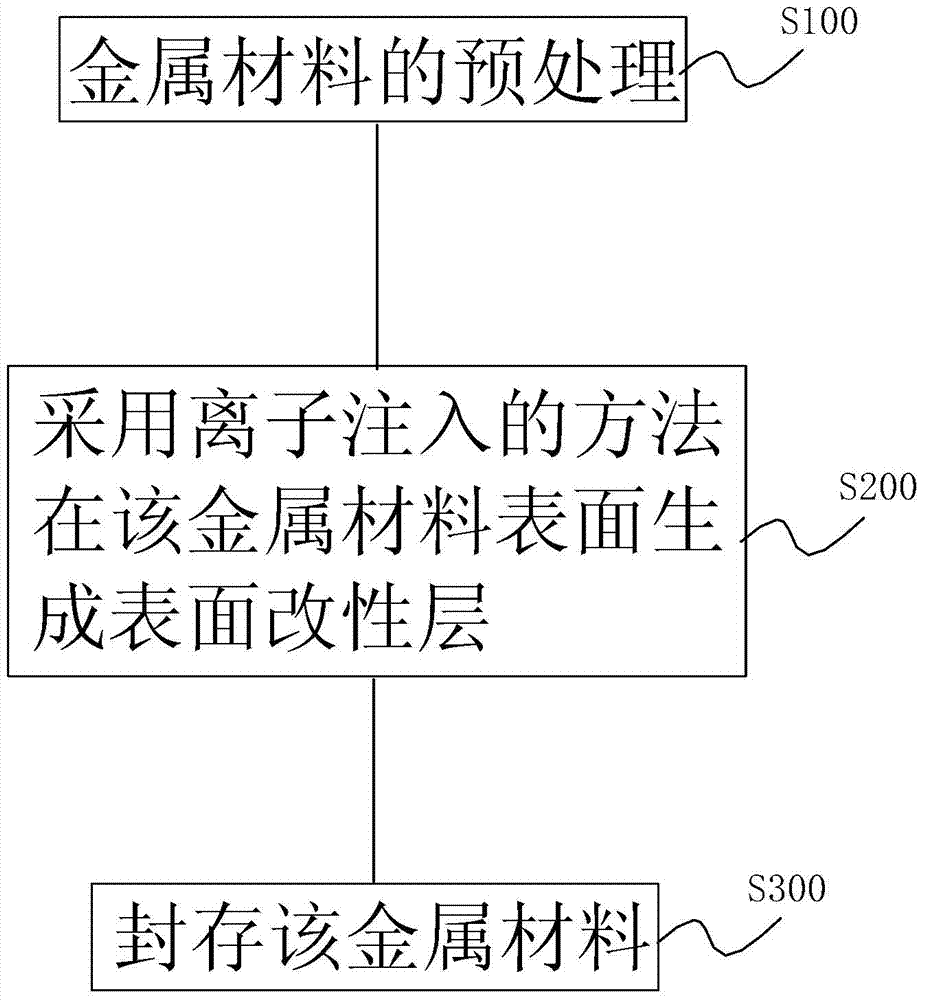

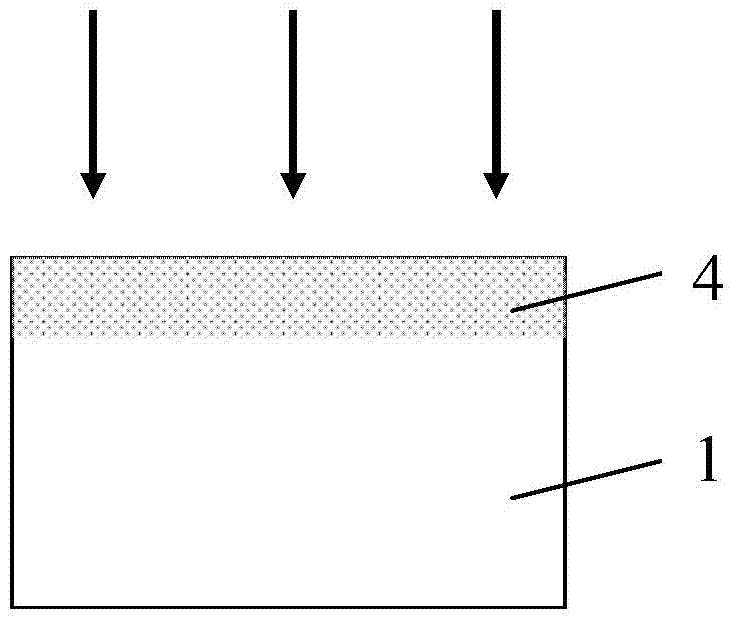

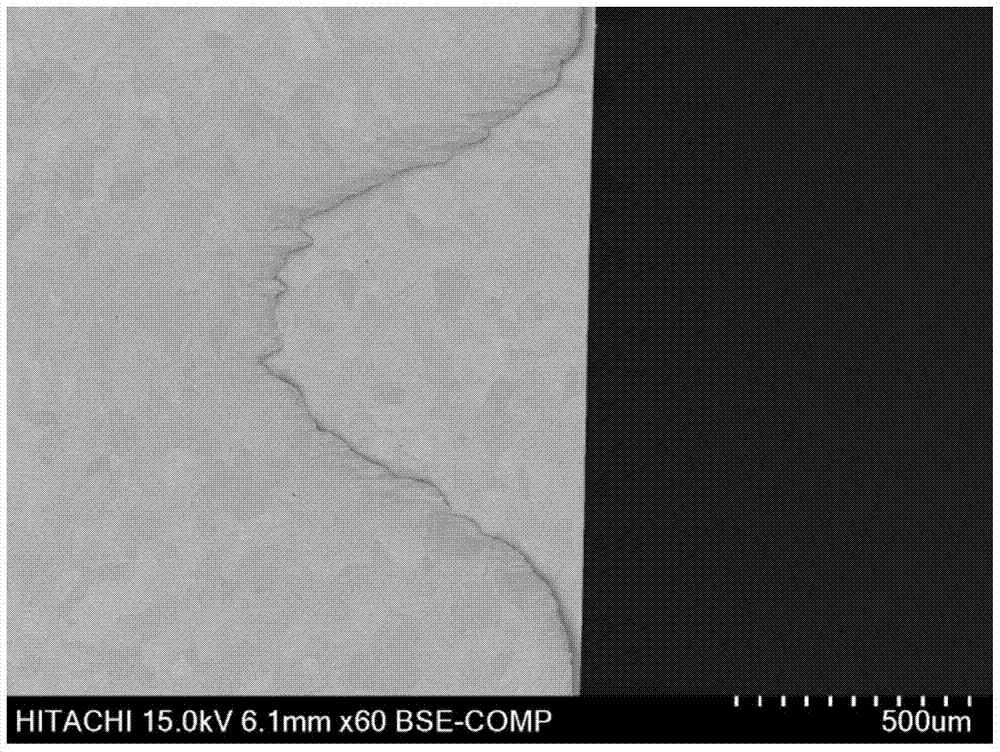

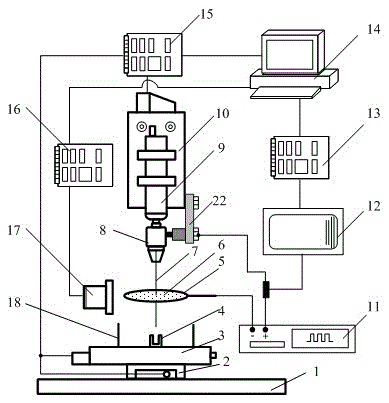

A method and device for manufacturing a surface modification layer of a metal material

ActiveCN104928643BReduce coefficient of frictionImprove wear lifeVacuum evaporation coatingSputtering coatingHigh pressureHigh load

A method and device for manufacturing a surface modification layer of a metal material, using an ion implantation method to modify the surface of a metal material with WS2 as a target, the manufacturing method includes pretreatment of the metal material; putting the metal material into a vacuum chamber , using the ion implantation method to generate a surface modification layer of the metal material with WS2 as the target material; the metal material after the surface modification layer is generated is cleaned, dried, and vacuum-sealed. The invention also discloses a metal material surface modification layer manufacturing device used in the manufacturing method. The invention uses ion implantation technology to prepare a tungsten disulfide solid lubricating functional layer on the metal surface, which can significantly reduce the surface friction coefficient of the workpiece without changing the size of the workpiece, and can be used for high temperature, high pressure, high vacuum, high load, high speed, high Lubrication of parts under harsh conditions such as radiation, strong corrosion, and ultra-low temperature.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

Laser induced metal surface layer composite TiC reinforcing method with TiO2, carbon black and methane as components

ActiveCN102978604BNo bonding issuesHigh hardnessHeat inorganic powder coatingSurface layerWear resistance

The invention discloses a laser induced metal surface layer composite TiC reinforcing method with TiO2, carbon black and methane as components, and relates to the technical field of metal surface reinforcement. The method comprises the following steps: applying TiO2 and carbon black mixed powder on a metal surface, and in methane atmosphere, scanning with laser beams on the metal surface to which the TiO2 and carbon black mixed powder is applied. By adopting the above method, TiC can be generated on the metal surface layer in an in-situ composite manner, thus enhancing the metal surface and improving the wear resistance.

Owner:路亚科消防车辆制造有限公司

Laser-induced metal surface composite TiCN strengthening method with tio2, isopropylamine, carbon black, methane and nitrogen as components

ActiveCN102995005BNo bonding issuesHigh hardnessMetallic material coating processesSurface layerNitrogen

The invention discloses a method for strengthening a laser induced metal surface layer composite TiCN by using TiO2, isopropylamine, carbon black, methanol and nitrogen as components, and relates to the technical field of strengthening treatment on metal surfaces. A mixture of the TiO2, the isopropylamine and carbon black is applied to the metal surface, and the metal surface applied with the mixture is scanned by a laser beam in a co-existence of the methanol and the nitrogen. By adopting the method, TiCN is generated by in-situ compounding of the metal surface layer, so that the strengthening to the metal surface and the abrasion resistance are realized.

Owner:NANTONG BEST MACHINE CO LTD

Method for strengthening compounding of TiCN on laser-induced metal surface layer taking TiO2, dimethylamine, carbon black, acetylene and nitrogen as components

ActiveCN102995010ANo bonding issuesHigh hardnessMetallic material coating processesSurface layerNitrogen

The invention discloses a method for strengthening the compounding of TiCN on a laser-induced metal surface layer by taking TiO2, dimethylamine, carbon black, acetylene and nitrogen as components and relates to the technical field of surface strengthening of metal materials. The method comprises the following steps of: coating the mixture of TiO2, the dimethylamine and the carbon black on a metal surface; and scanning on the mixture-coated metal surface by using a laser beam under the condition that acetylene and nitrogen coexist. Through the method, TiCN can be generated on the metal surface layer through in-situ compounding so that a carbon structural steel surface is strengthened and the wear resistance is improved.

Owner:海安华诚新材料有限公司

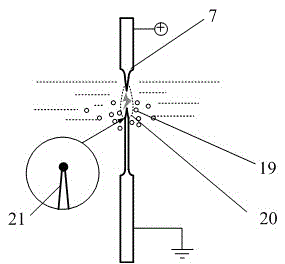

Preparation method of submicron spherical electrode

ActiveCN103680760BImprove surface qualityNo bonding issuesMachining electrodesElectrical-based machining electrodesCondensation processPulse electrochemical machining

A submicron ball-point electrode preparation device and a method belong to the field of precision and microfine manufacturing and measurement. By a liquid film pulse electrochemical machining method, a submicron probe with good surface quality can be prepared. On this basis, a submicron ball-point tool electrode is prepared through instant micro-discharge fusion and condensation processes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com