Laser-induced wheel pair surface strengthening and finishing processing method

A technology of finishing and surface strengthening, applied in metal processing, heating inorganic powder coating, etc., can solve the problems of worker's health damage, large surface roughness, long production cycle, etc., saving machining time and surface roughness. The effect of low intensity and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

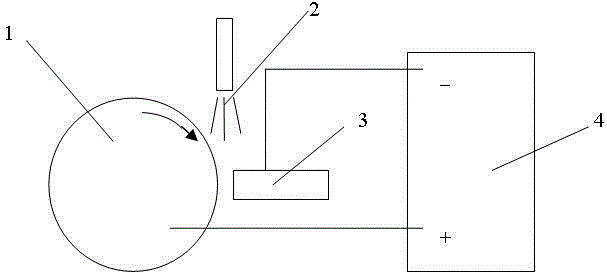

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Taking the in-situ recombination of Ti(C,N) on the metal surface as an example, laser-induced strengthening was first performed on the tread and rim of the wheel. The mixing mass ratio of TiO2, formamide and carbon black powder was 5:5:4. The power is 1300W, the flow rates of acetylene and nitrogen are 6L / min and 8L / min respectively, the scanning speed of the laser beam is 400mm / min, the laser wavelength is 10.6μm, the spot diameter is 3mm, and the rotation speed of the wheel set is 7r / min. The Ti(C,N) layer with a thickness of up to 400 μm is compounded in situ on the wheel tread and the wheel rim surface, and the microhardness can reach HV2700.

[0026] Polishing was performed using the pulse current electrochemical finishing technology with the following process parameters: pulse frequency 9KHz, pulse current value 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com