Plasma immersion ion injection method for improving anti-oxidation property of copper film

A plasma immersion and anti-oxidation technology, applied in ion implantation plating, coating, metal material coating process, etc., can solve the problems of increased production cost, environmental pollution, complicated preparation process, etc. Controllability, Antioxidant Improvement, Highly Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The substrate is a 2cm×2cm ordinary glass slide. Take some slides of this specification, degrease them, then ultrasonically clean them in deionized water, anhydrous acetone and anhydrous ethanol in turn, dry them, and then fix them on a magnetron sputtering On the sample stage of the sputtering equipment, pure copper with a purity of 99.99% is used as the target material, and the linear distance between the target material and the center of the sample stage is 10 cm, and the magnetron sputtering equipment is sealed. Before depositing the copper film, the glass slide needs to be cleaned by sputtering. The process is as follows:

[0038] Vacuum down to 4×10 -3 Pa, the Ar working gas is introduced, the flow rate is 20SCCM, and the working pressure is maintained at 4×10 -1 Pa, open voltage to 500V (at this time the copper target is temporarily shielded by a partition), and the cleaning time is as long as 5min.

[0039] After cleaning, remove the copper target separator, m...

Embodiment 2

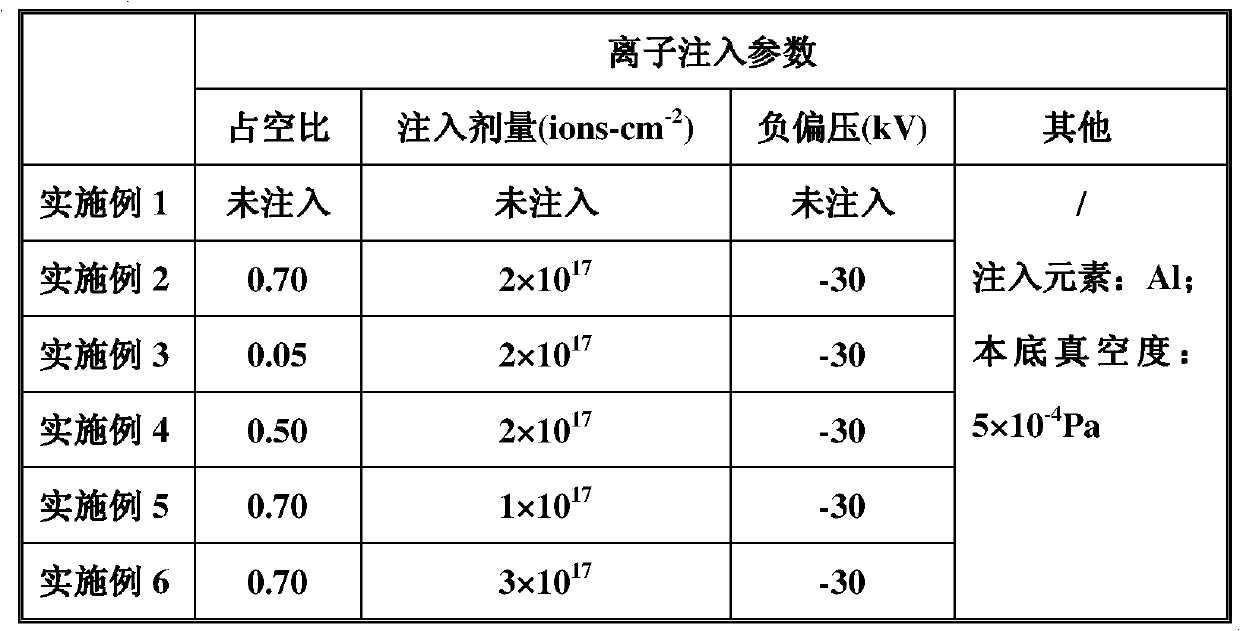

[0047] Referring to Example 1, the glass slide with the copper film was fixed on the sample stage of the plasma immersion ion implantation equipment, and the airtight equipment was evacuated to 5 × 10 -4 Pa, and then carry out Al plasma immersion ion implantation, other implantation parameters are as follows:

[0048] Duty cycle: 0.70; workpiece negative bias: -30kV; injection dose: 2×10 17 ions-cm -2 .

[0049] Place the injected copper film in a heating furnace for oxidation, and the parameters are the same as the oxidation process in Example 1.

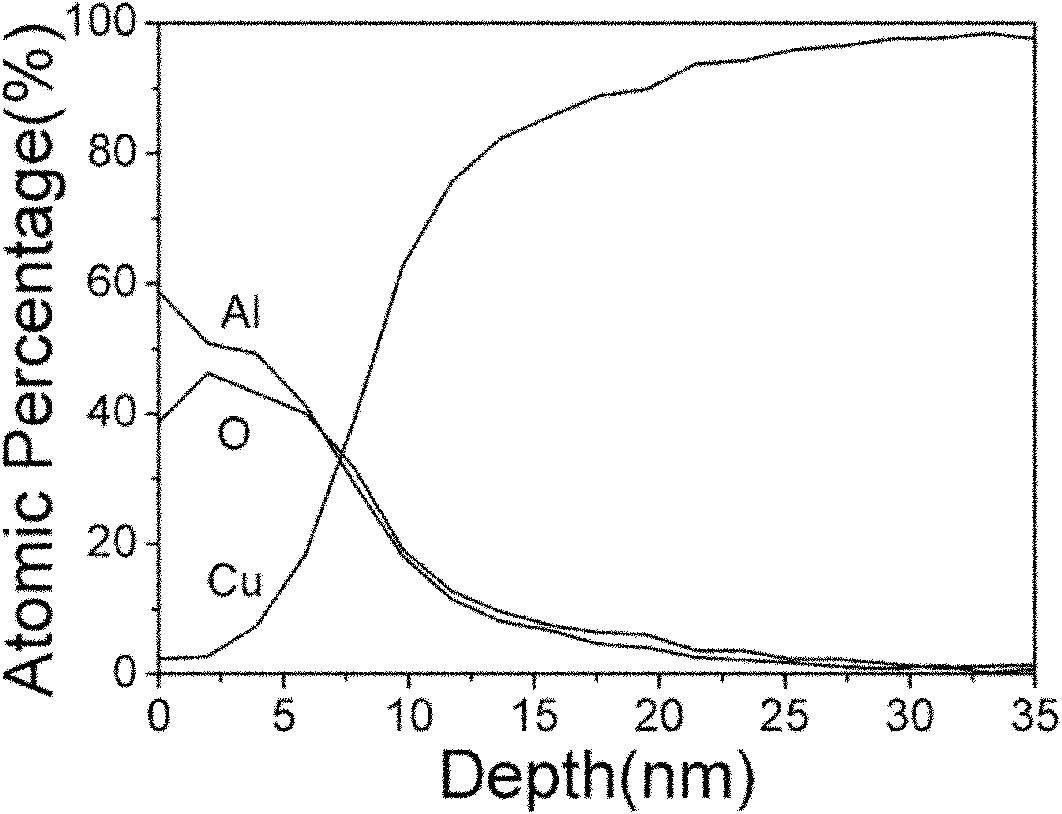

[0050] According to the XPS results, the maximum oxygen depth of the implanted copper film surface layer after oxidation is 120nm, as shown in the attached figure 1 shown;

[0051] The four-probe test results show that the surface resistance of the implanted copper film before oxidation is 0.37ohm / sq, and the resistance after oxidation is 1.65ohm / sq.

Embodiment 3

[0053] The glass slide with the copper film in Example 1 is fixed on the sample stage of the plasma immersion ion implantation equipment, and the airtight equipment is evacuated to 5 × 10 -4 Pa, and then carry out Al plasma immersion ion implantation, other implantation parameters are as follows:

[0054] Duty cycle: 0.05; workpiece negative bias: -30kV; injection dose: 2×10 17 ions-cm -2 .

[0055] Place the injected copper film in a heating furnace for oxidation, and the parameters are the same as the oxidation process in Example 1.

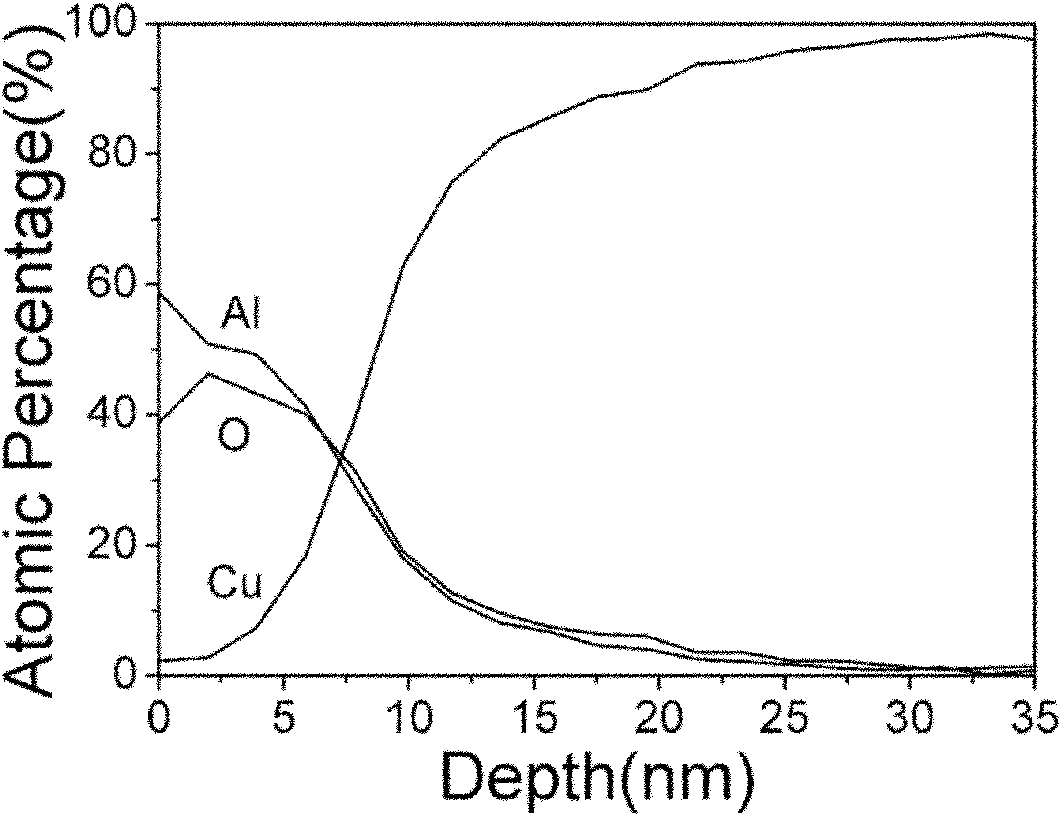

[0056] According to the XPS results, the maximum depth of oxygen injected into the surface layer of copper film after oxidation is about 30nm. figure 2 shown;

[0057] The four-probe test results show that the surface resistance of the implanted copper film before oxidation is 0.42ohm / sq, and the resistance after oxidation is 0.58ohm / sq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com