A kind of preparation method of thermally stable NdFeB magnet

A NdFeB, thermally stable technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of poor thermal stability, reduced service life, and performance degradation of magnets, and achieve coercive force reduction, The effects of sufficient wrapping and reduced magnetic remanence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

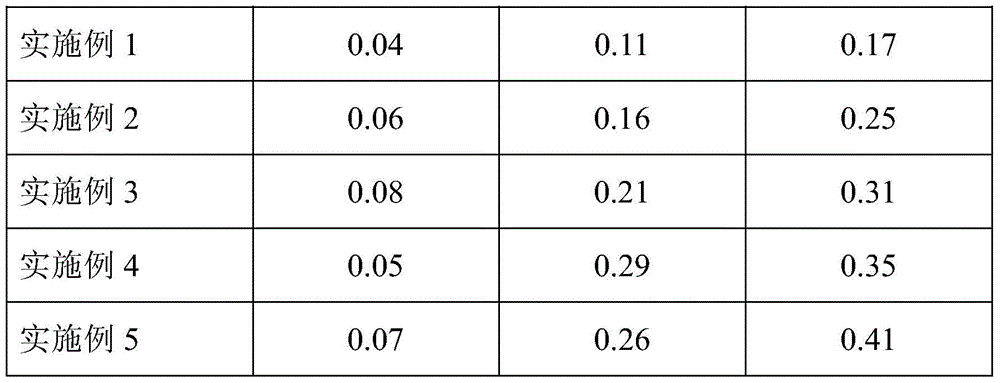

Examples

Embodiment 1

[0021] A method for preparing a thermally stable NdFeB magnet, comprising the following steps:

[0022] (1) Equipped with NdFeB magnetic powder, which is composed of the following components by weight percentage: Nd 25%, Ho 4%, F 2.6%, Ni 1.8%, Co 0.12%, Al 0.1%, B 0.95%, and the balance is Fe; When there are accidental impurities in the raw materials, or when trace impurities are introduced in the preparation process, it will not affect the completion of the present invention; F is added in the form of metal fluoride required in the proportioning;

[0023] (2) Mix the silane coupling agent KH-560 of 2% by weight of the magnetic powder and 150% of acetone and add it into the magnetic powder, and then vibrate for 1.5 hours with a 50KHz ultrasonic wave;

[0024] (3) Add 1.8% accelerator (N,N-dimethylaniline) of magnetic powder weight, 150% acetone and 11.5% epoxy resin, then oscillate with 50KHz ultrasonic waves for 1.5 hours and dry until the solid content 80wt%;

[0025] (4)...

Embodiment 2

[0027] A preparation method of a thermally stable NdFeB magnet is the same as in Example 1 except for the following parts: Nd 27%, Ho3%, F 2.8%, Ni 0.1%, Co 0.95%, Al 0.1%, B 1.05%, The balance is Fe. The preparation method is the same as in Example 1.

Embodiment 3

[0029] A preparation method of a thermally stable NdFeB magnet is the same as in Example 1 except for the following parts: Nd 27%, Ho 5%, F 2.8%, Ni 2.0%, Co 0.95%, Al 0.35%, B 1.05%, The balance is Fe. The preparation method is the same as in Example 1.

PUM

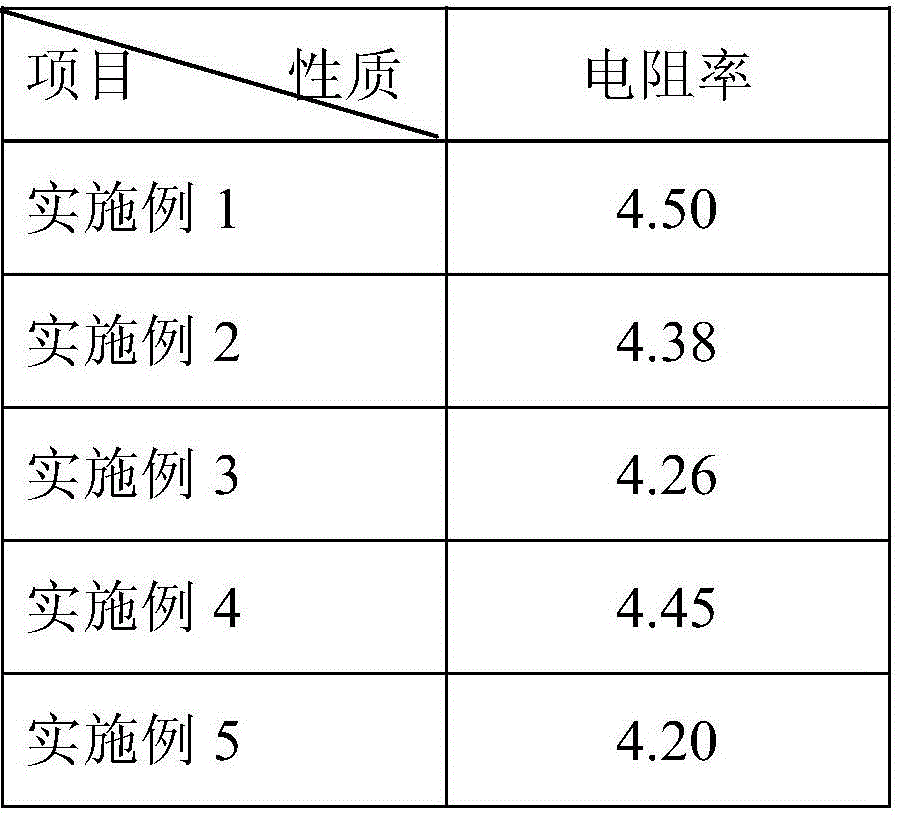

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com