Preparation method for powder defoaming agent

A technology of powder defoamer and starch, which is applied in the direction of foam dispersion/prevention, etc. It can solve the problems of poor defoaming stability, slowing down the release speed of defoaming active substances, and reducing the number of rinsing times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

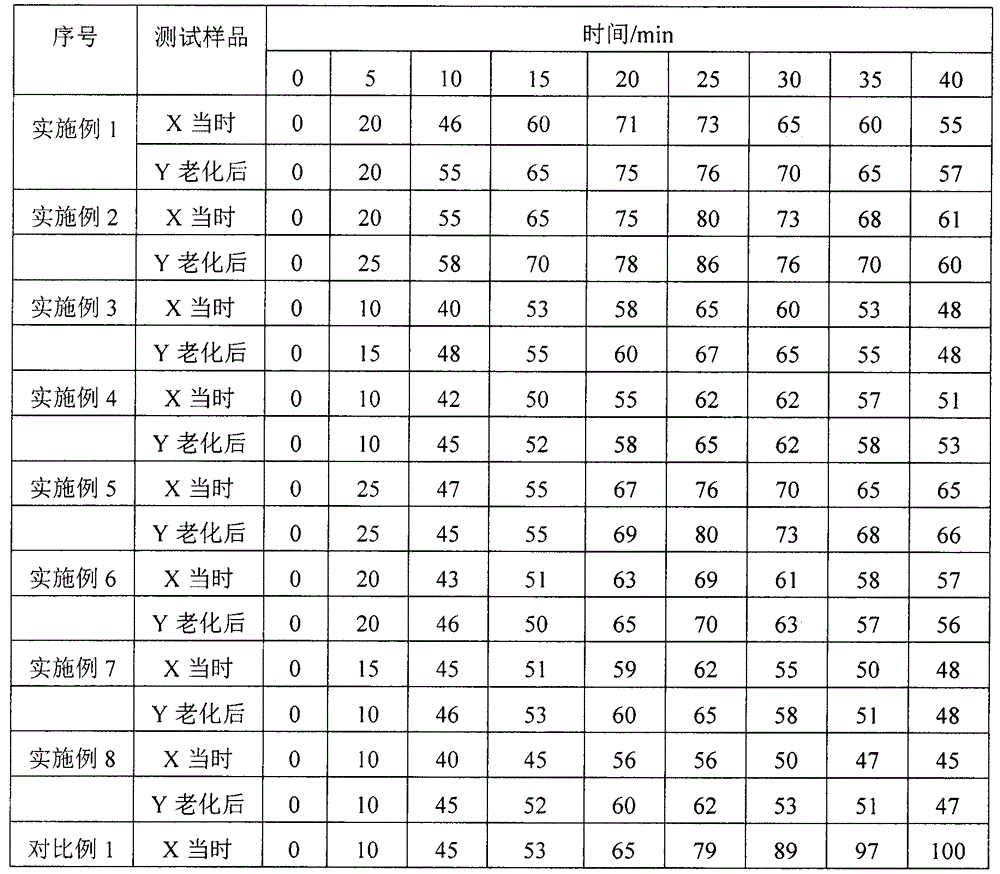

Examples

preparation example Construction

[0039] Preparation of antifoam actives

[0040] Polydimethylsiloxane with a viscosity of 800mPa·s, MQ resin (M:Q=0.66), and catalyst (mixed with KOH and methyl silicone oil) are first mixed, heated to 100°C to react, and then added with a specific surface area of 80m 2 / g hydrophobic silica, control the temperature of the reaction system and keep it warm at 100°C for 3h, and finally react for 1h at a vacuum degree of -0.02MPa to make the reaction more thorough, and finally cool to room temperature to obtain a dispersant with a viscosity of 50,000mPa·s foam actives.

Embodiment 1

[0043] Add 200g of antifoam active material with a viscosity of 1,000mPa·s, 50g of carboxymethyl cellulose and 20g of water into a mixer, mix with a disperser at 25°C, the speed is 500rpm, and the dispersion time is 10min to obtain a viscosity of 50,000mPa · s mixture M;

[0044] At room temperature, 80 g of 0.1 mol / L citric acid-sodium citrate buffer solution was added to 550 g of cornstarch, and stirred in a mixer for 5 minutes at a speed of 70 rpm to obtain intermediate N;

[0045] Add the mixture M, the intermediate N and 100 g of sodium polyacrylate into the mixer and mix with the rotation speed of the mixer at 1,000 rpm. Finally, dry the obtained powder through a drier to obtain a solid powder defoamer.

Embodiment 2

[0047] Add 50g of antifoaming active material with a viscosity of 50,000mPa·s, 10g of hydroxyethyl cellulose and 10g of water into a mixer, mix with a disperser at 100°C, the speed is 2,000rpm, and the dispersion time is 60min to obtain a viscosity of 100,000 mPa·s mixture M;

[0048] At room temperature, 60g of 0.2mol / L acetic acid-sodium acetate buffer solution was added to 850g of phosphodiester starch, and stirred in a mixer for 60min at a speed of 75rpm to obtain intermediate N;

[0049]Add the mixture M, the intermediate N and 20 g of polyacrylic acid into the mixer and mix them. The rotation speed of the mixer is 2,500 rpm. Finally, the obtained powder is dried by a dryer to obtain a solid powder defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com