Preparation method of multi-purpose in-level oil-water separation material

An oil-water separation and grading technology, applied in the field of preparation of graded porous composite mesh membrane, can solve the problem of inability to separate metal ions, and achieve the effect of fast and effective adsorption process, improved adsorption time, and rapid process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

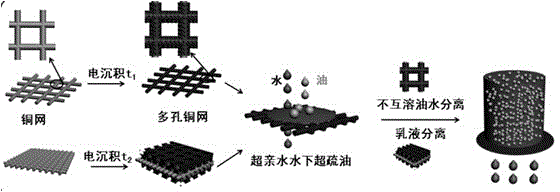

[0039] Specific implementation mode 1: In this implementation mode, graded oil-water separation materials are prepared according to the following steps:

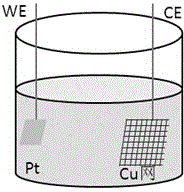

[0040] (1) Preparation of mesh porous Cu film

[0041] The porous Cu thin film (20-400 mesh) was prepared by the hydrogen bubble template method, and the specific steps were as follows: after the copper mesh substrate was acid-washed and alkali-washed to remove oil and oxides, a platinum sheet was used as the anode (2×2cm 2 ), copper mesh as counter electrode cathode (3×3cm 2 ) for electrodeposition ( figure 1 ), the bath composition includes 0.02-4mol L -1 CuSO 4 and 0.1-5mol L -1 h 2 SO 4 , pH=4.0±0.5, current density is 0.1-8.0A·cm -2 , the deposition time is 5-40s.

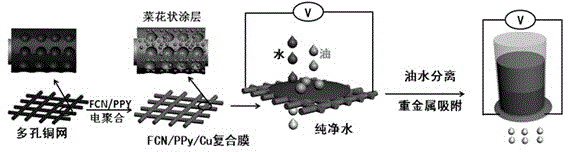

[0042] (2) Preparation of FCN / PPy composite film coating on mesh porous Cu film

[0043] The above-mentioned mesh porous Cu film is immersed in the prepared mixed solution, and the mixed solution contains 0.5-20mmol L-1 Pyrrole, 0.5-20mmol L -1 K ...

specific Embodiment approach 2

[0050] Specific embodiment two: In this embodiment, a multifunctional oil-water separation membrane is prepared according to the following steps:

[0051] (1) Preparation of mesh porous Cu film

[0052] Hydrogen bubble template method was used to prepare mesh porous Cu film (substrate copper mesh 100 mesh), and the specific steps were as follows: after pickling and alkaline cleaning of copper mesh substrate to remove oil and oxides, platinum sheet was used as anode (2 × 2 cm 2 ), copper mesh as counter electrode cathode (3×3cm 2 ), the bath composition includes 0.2mol L -1 CuSO 4 and 1mol L -1 h 2 SO 4 , pH=4.0±0.5, the current density is 8A cm -2 , the deposition time is 10s. The electron micrograph of the microscopic morphology of the mesh porous Cu thin film is shown in Figure 4 , it can be seen from the figure that the copper mesh presents a hierarchical porous structure.

[0053] (2) Preparation of FCN / PPy composite film coating on mesh porous Cu film

[0054] ...

specific Embodiment approach 3

[0064] Specific embodiment three: In this embodiment, a multifunctional oil-water separation membrane is prepared according to the following steps:

[0065] (1) Preparation of mesh porous Cu film

[0066] Hydrogen bubble template method was used to prepare mesh-like porous Cu film (substrate copper mesh 300 mesh), and the specific steps were as follows: after acid-washing and alkali-washing the copper mesh substrate to remove oil and oxides, a platinum sheet was used as an anode (2 × 2 cm 2 ), copper mesh as counter electrode cathode (3×3cm 2 ), the bath composition includes 0.4mol L -1 CuSO 4 and 1mol L -1 h 2 SO 4 , pH=4.0±0.5, the current density is 7A cm -2 , the deposition time is 20s. The electron micrograph of the microscopic morphology of the mesh porous Cu thin film is shown in Figure 5 , it can be seen from the figure that a porous mesh with a dense pore size can be obtained by electrodeposition of a dense copper mesh.

[0067] (2) Preparation of FCN / PPy co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com